Electric rail clamping device of throw-off carriage

A technology of rail clamps and unloading vehicles, which is applied in the direction of conveyor objects, transportation and packaging, etc., which can solve the problems of poor operation reliability, complicated structure, and danger, and achieve high safety and reliability, simple structure, and high applicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

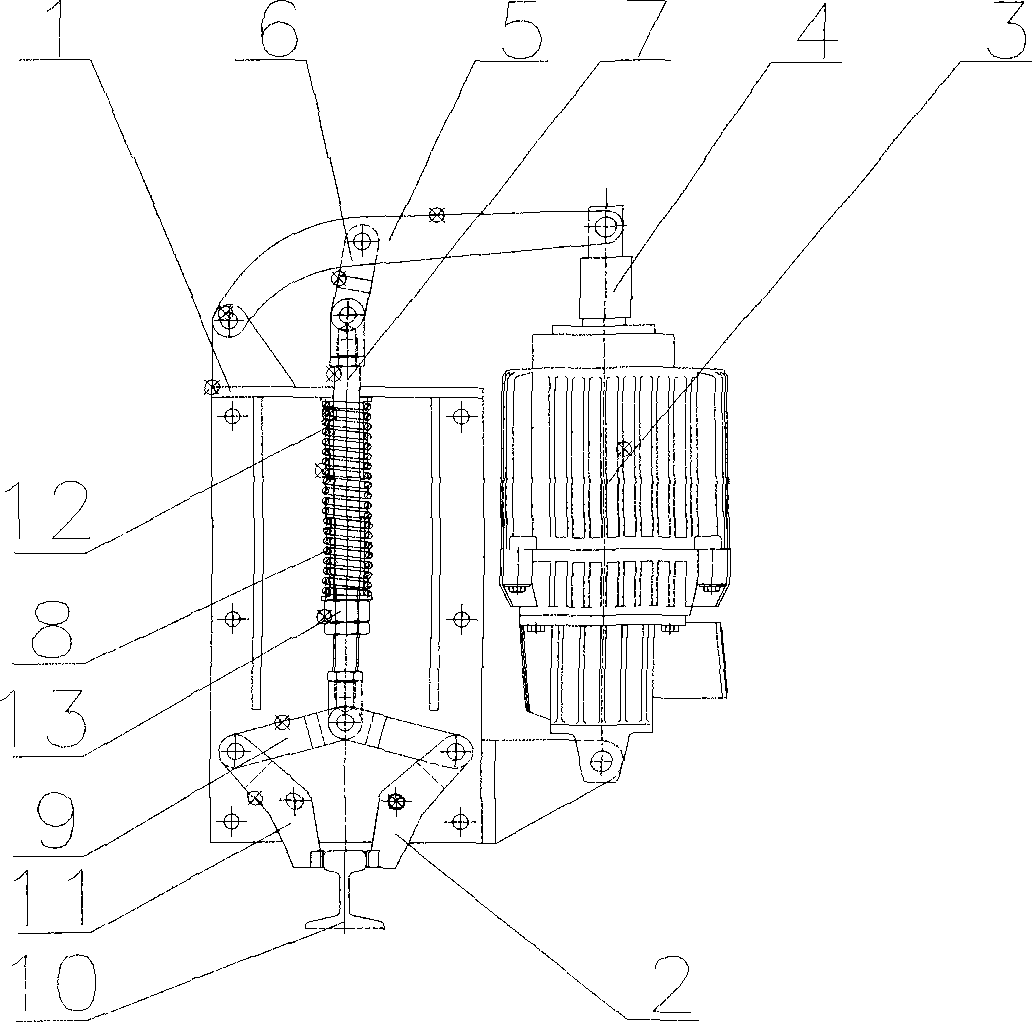

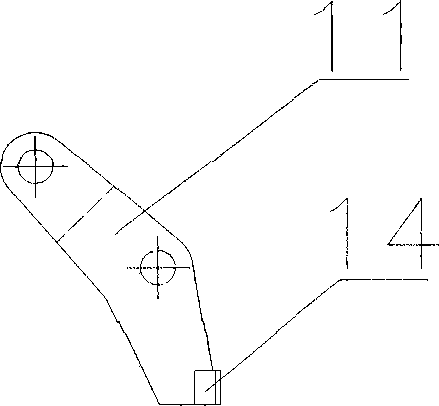

[0018] see figure 1 , an electric rail clamp for an unloading vehicle provided by the present invention includes a rail clamp bracket 1 arranged on one side of the unloading vehicle, and a rail clamp 2 connected by power and an electric rail clamp are installed on the rail clamp bracket 1 . Hydraulic push rod pusher 3, a large connecting rod 5 is hinged between the top of the rail clamp bracket 1 and the push rod 4 on the top of the electrohydraulic push rod pusher 3, and an upper connecting rod is hinged below the large connecting rod 5 in turn 6 and the main strut 7, the outer wall of the main strut 7 is covered with a spring 8, the rail clamp 2 includes two sets of lower links 9 hinged at the bottom of the main strut 7 at the same time, the two sets of lower links 9 two groups of clamping blocks 11 for clamping the track 10 are hinged symmetrically at the bottom.

Embodiment 2

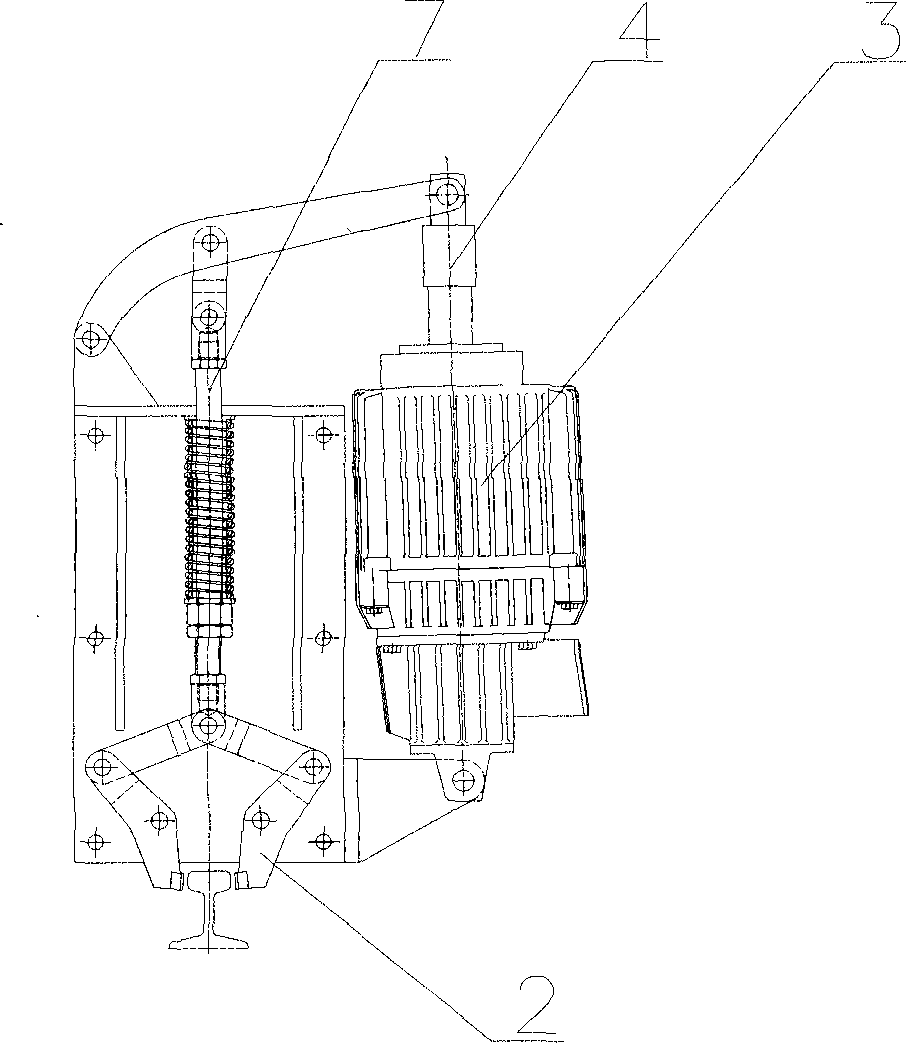

[0020] The working process of the present invention is: when the electrohydraulic push rod pusher 1 is energized, its push rod 4 is pushed out, and the thrust is transmitted to the main strut 7 through the connecting rod mechanism, so that the main strut 7 moves upward, and the rail clamp 2 Complete the release action (such as figure 2 On the contrary, when the push rod 4 is retracted, the main strut 7 pushes the lower link 9 under the pre-compression force of the spring 8, so that the lower end of the clamping block 11 clamps the track 10.

Embodiment 3

[0022] As a further improvement to Embodiment 1, a guide sleeve 12 is provided between the spring 8 and the main strut 7 to prevent the spring 8 from being deformed after being compressed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com