Safety valve maintenance platform

A technology of safety valve and maintenance platform, which is applied in the direction of workbench, lifting device, lifting frame, etc., can solve problems such as hidden safety hazards, dumping of safety valve, inconvenient disassembly, etc., and achieve the effect of improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific drawings and embodiments.

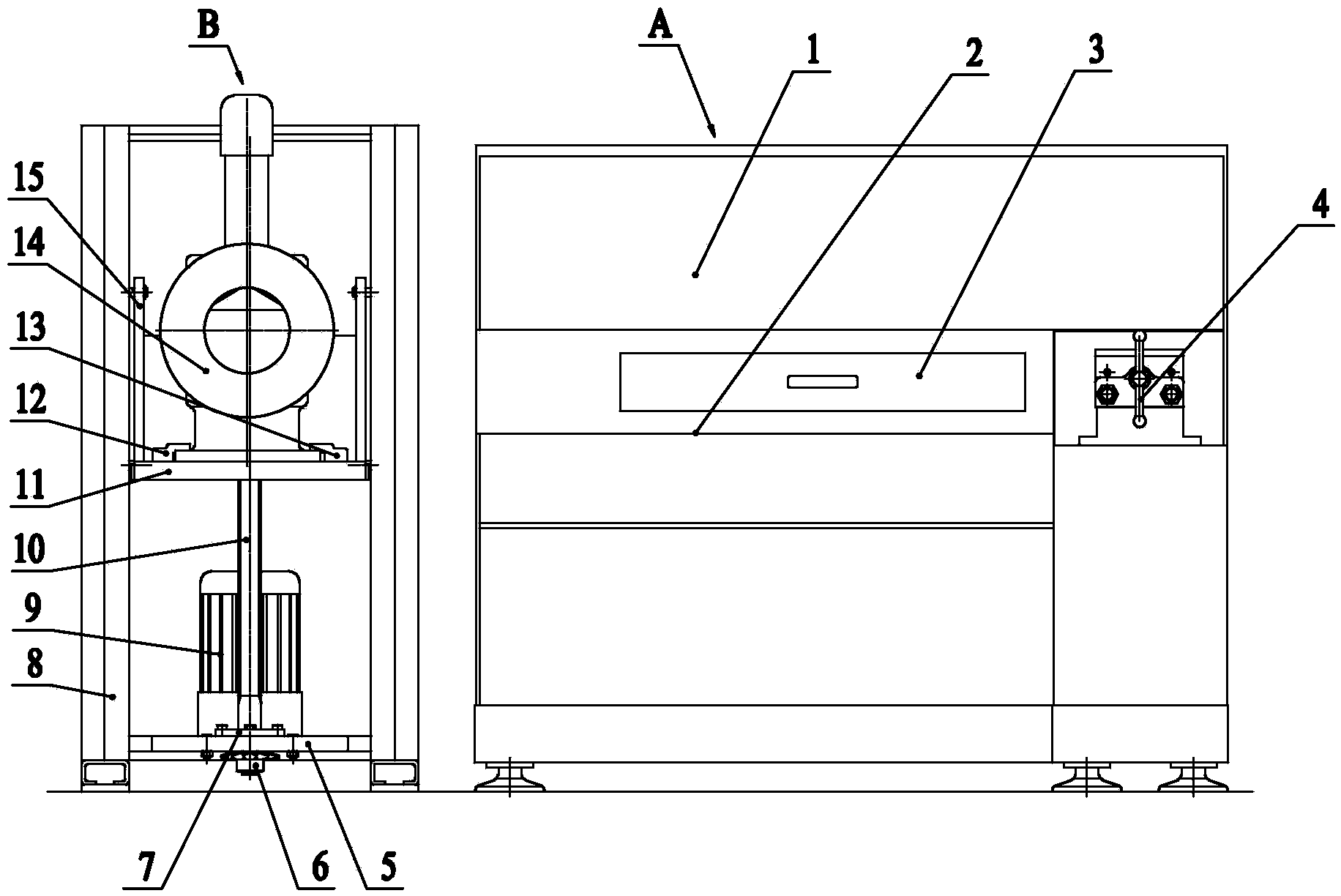

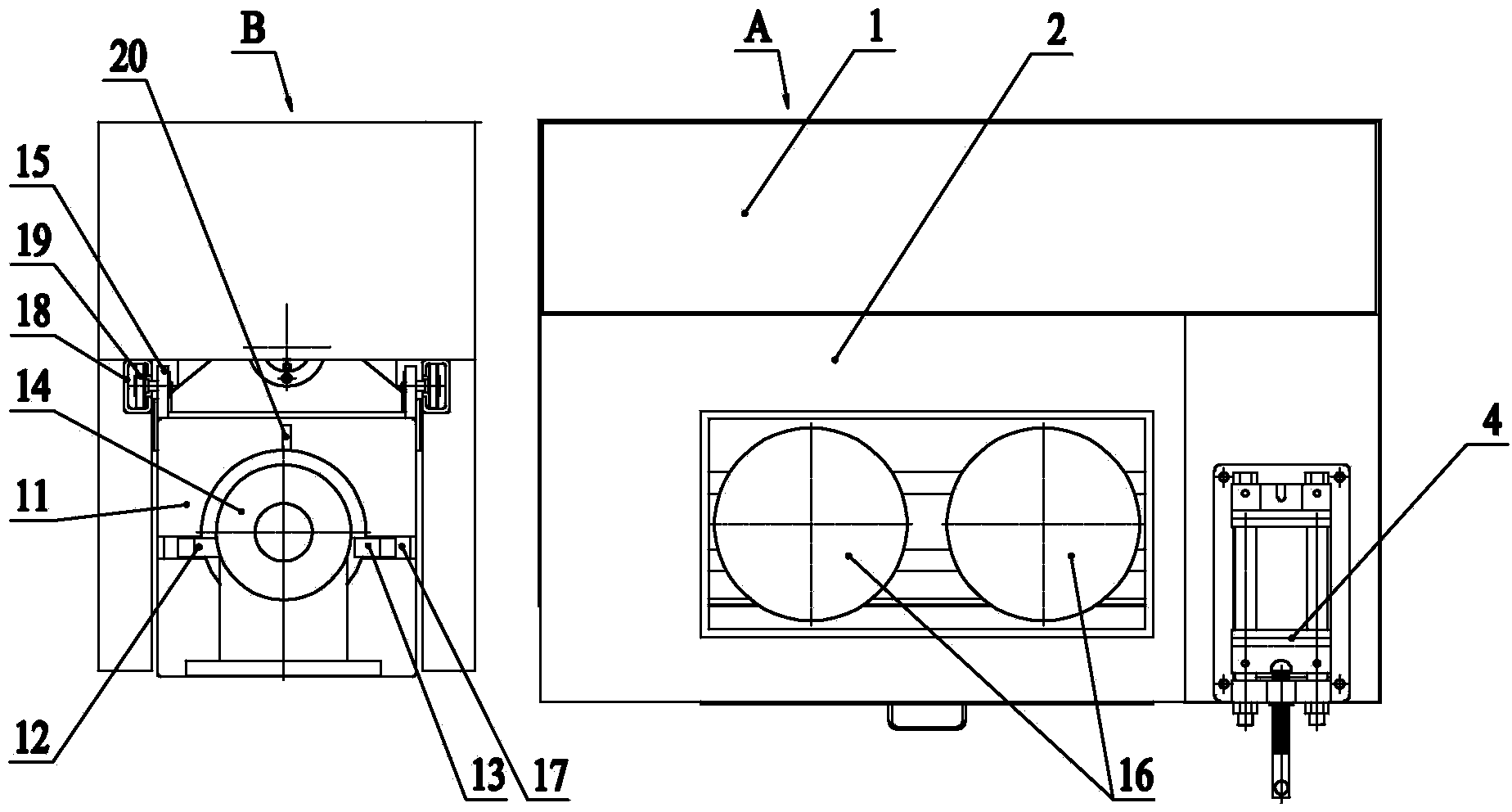

[0021] As shown in the figure: the safety valve repair station in the embodiment mainly includes two parts, a repair workbench A and a hoist B.

[0022] Such as figure 1 , figure 2 As shown, the rear part of the maintenance workbench A is a workbench shell 2, and the front part of the maintenance workbench A is provided with a worktable 2, on which a grinding plate 16 is arranged, and on the right side of the workbench 2 There are vise 4. There are two grinding plates 16 on the worktable 2, one is a coarse grinding plate 16, and the other is a fine grinding plate 16. A drawer 3 is arranged inside the workbench housing 2 .

[0023] Such as figure 1 , figure 2 As shown, the lifts B are arranged side by side on the left side of the maintenance workbench A, and the lifts B are used to lift the safety valve 14 to be maintained to a height suitable for disa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com