Rotation type steering column sub-packing platform

A technology of steering column and sub-assembly table, which is applied in the direction of assembly machine, workbench, transportation and packaging, etc. It can solve the problems of inconvenient assembly of steering column sub-assembly table, failure of torque sensor, large site occupancy, etc. Achieve the effect of improving the utilization rate of the site, eliminating the dead angle of transfer and ensuring the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

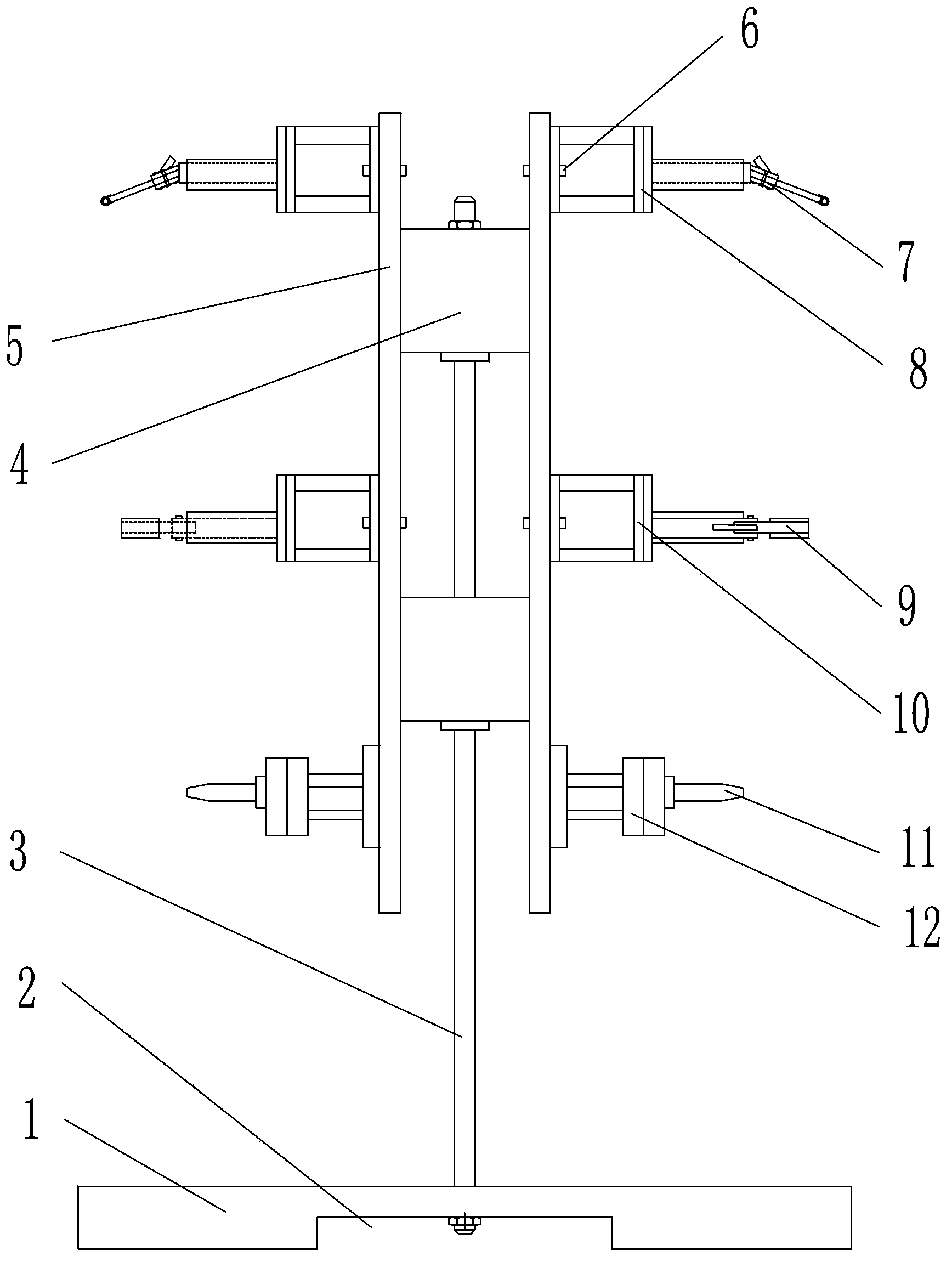

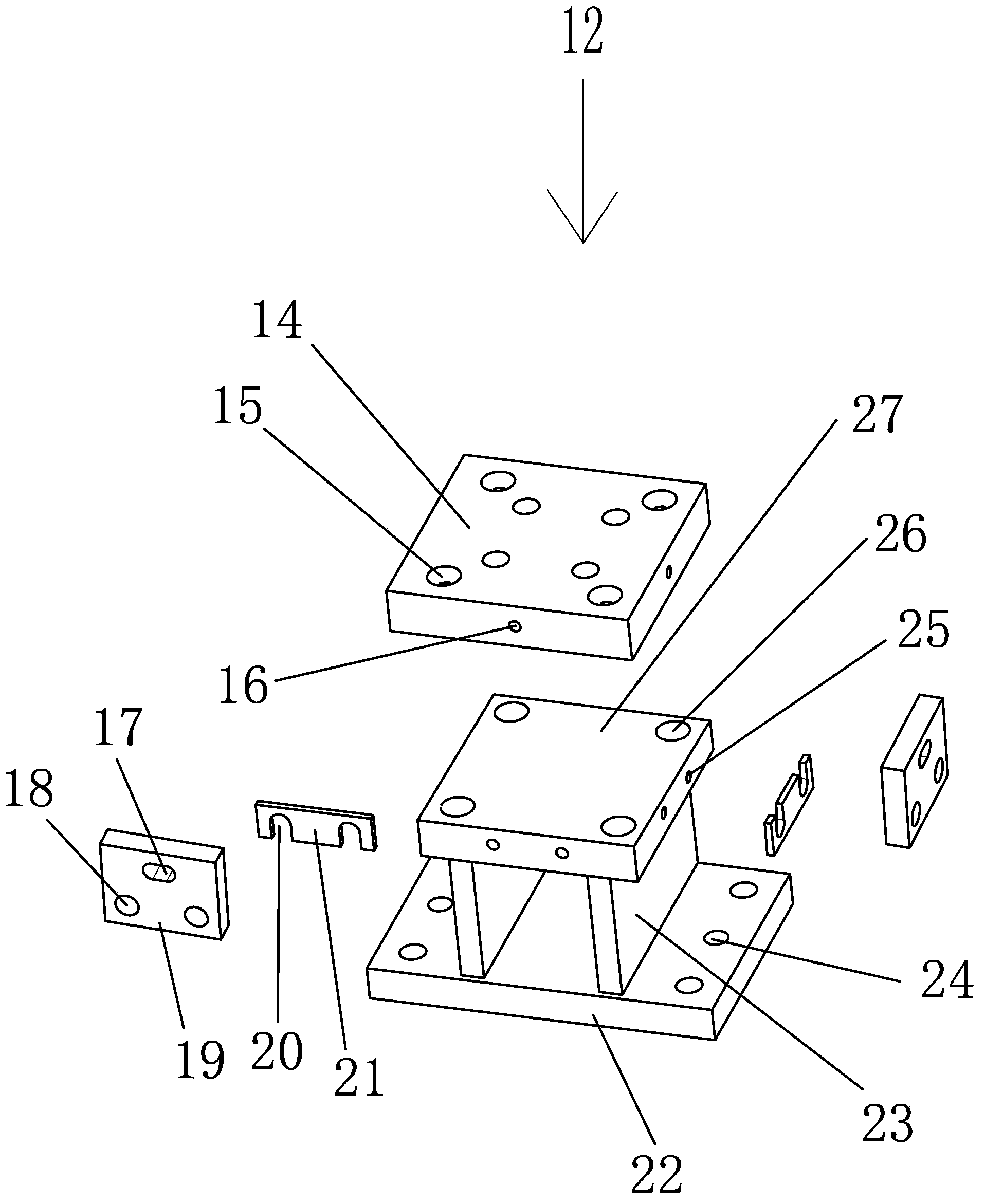

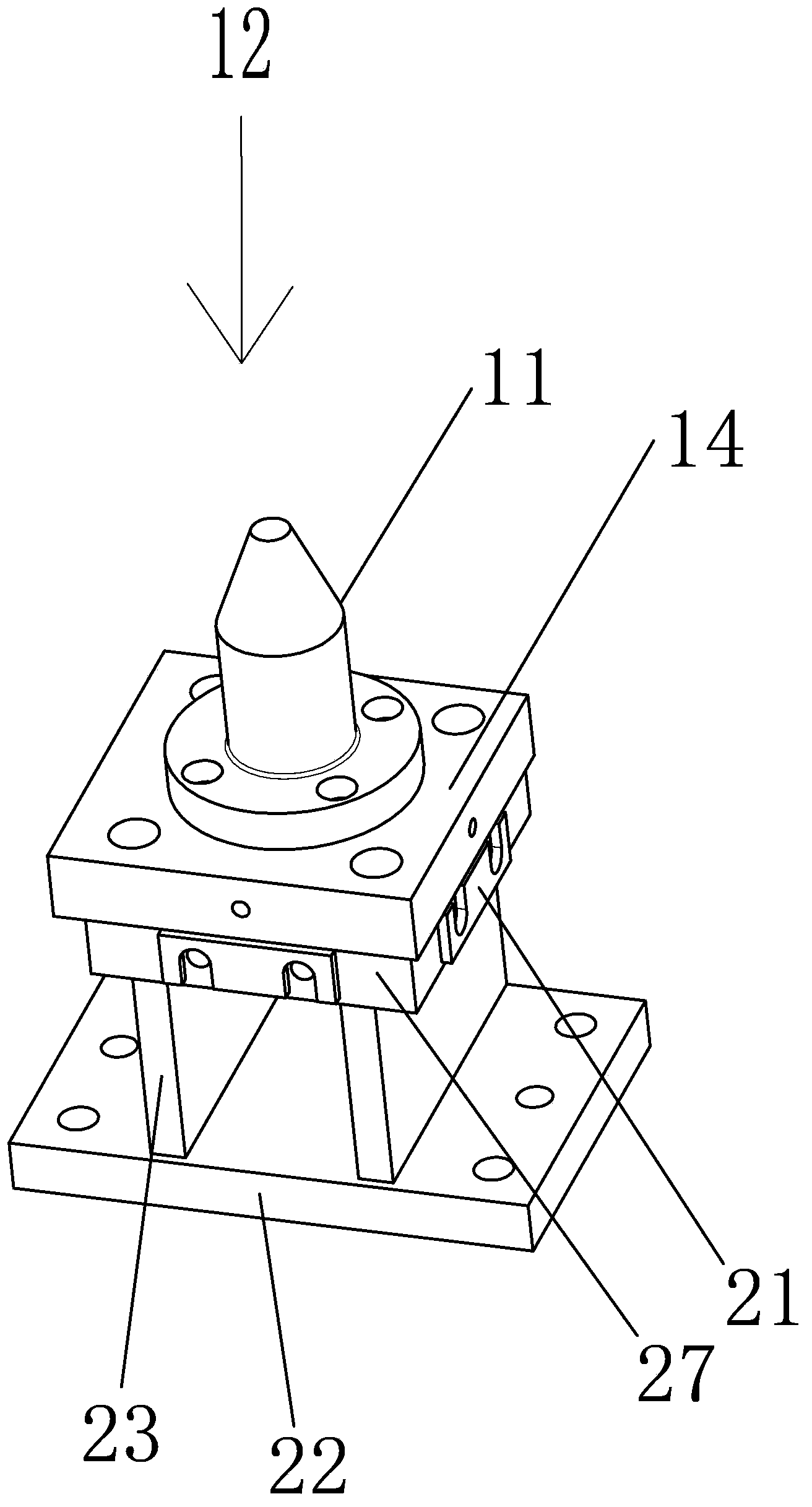

[0034] Embodiment: a kind of rotary steering column packing table, such as figure 1 , Figure 5 , Figure 6 As shown, it includes: including: a base 1, a bearing 4, a vertical plate 5 and a displacement bolt 6, a vertical column 3 is erected and fixed on the base, the bearing sleeve is tightly fixed and installed on the vertical column, and the vertical plate is fixedly connected vertically On the outer surface of the bearing, a vertically downward upper chute 28 is provided on the upper end of the vertical plate, and a vertical downward downward chute 29 is provided on the vertical plate below the upper chute, and the center of the upper chute The centerlines of the line and the lower chute are on a straight line; in the upper chute, a horizontally outwardly facing ignition switch locking pliers mounting seat 8 is installed on the upper chute, and on the ignition switch locking pliers mounting seat 8 is fixedly installed with The ignition switch locking pliers 7 facing outw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com