Washer feeding device

A technology of feeding device and washer, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low production efficiency, delay, and excessive labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

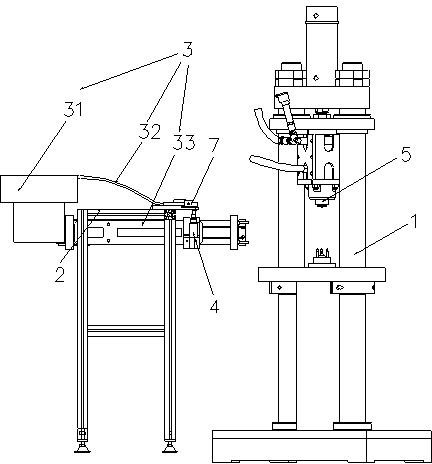

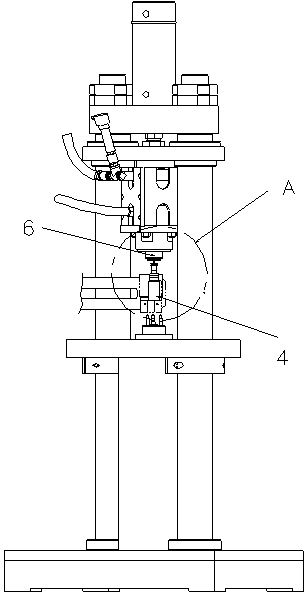

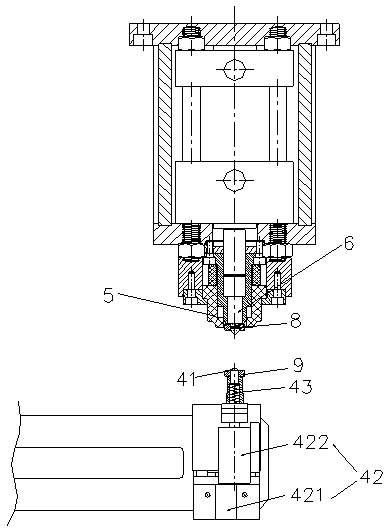

[0028] like figure 1 ,like figure 2 ,like image 3 and as Figure 4 As shown, a gasket feeding device is applied to the feeding device for conveying metal gaskets, including a frame 1 and a workbench 2, and a feeding mechanism 3 and a retrieving manipulator 4 are installed on the workbench 2, and on the frame 1 is provided with a first station to be processed 5, and an indenter 6 capable of absorbing the washer 9 is installed at the first station to be processed 5, and a magnet 8 is provided at the end of the indenter 6. The washer 9 is adsorbed by the set magnet 8, and the washer 9 on the reclaiming manipulator 4 is adsorbed to the pressure head 6, so as to prepare for the subsequent assembly work.

[0029] It also includes an automatic control device, through which the feeding status of the gasket feeding device is controlled to achieve an automatic effect.

[0030] The retrieving manipulator 4 is arranged below the feeding mechanism 3, and the workbench 2 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com