Apparatus for guiding tube processing devices

A technology of processing device and guide tube, applied in metal processing equipment, pipe cutting device, manual planing equipment, etc., can solve problems such as being unsuitable for pipe processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

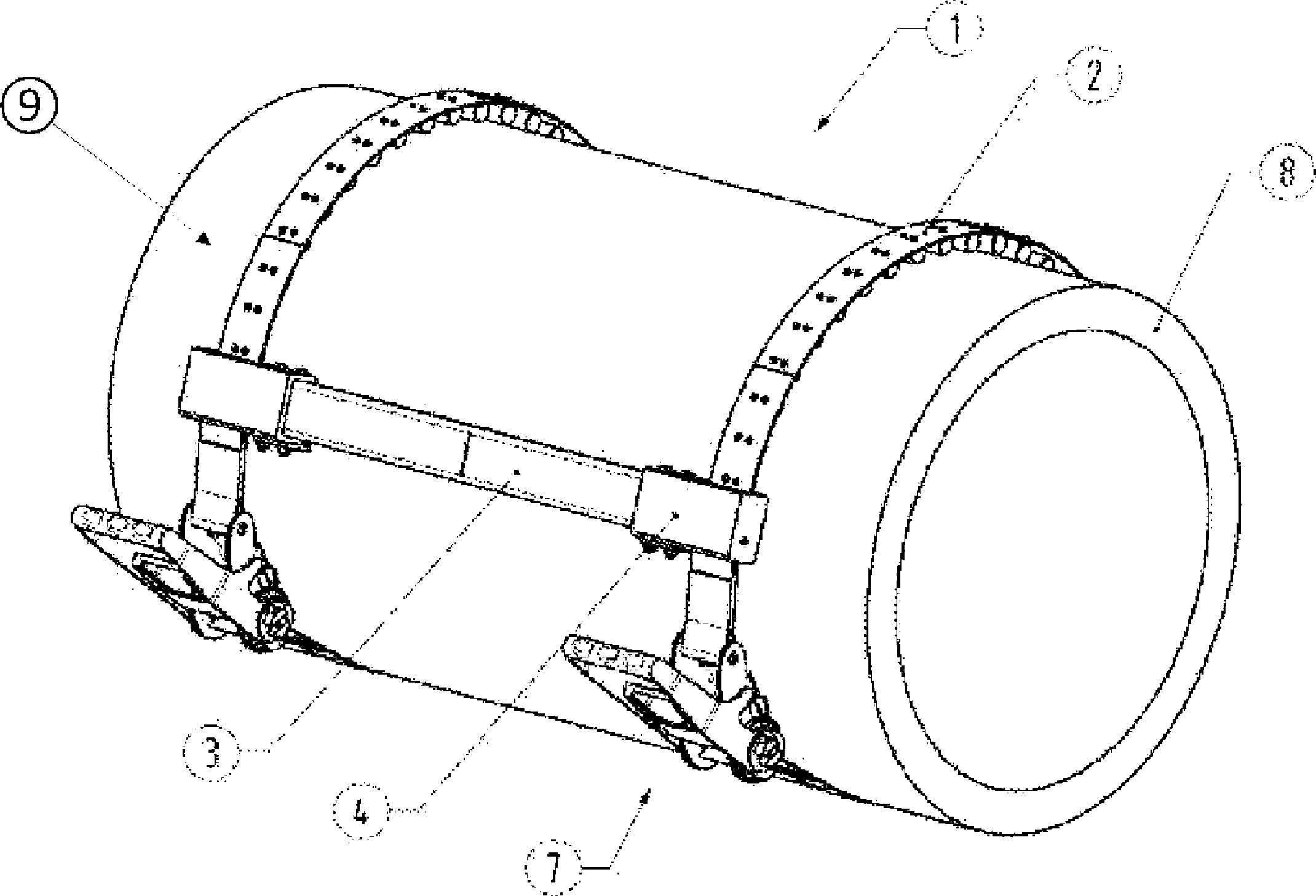

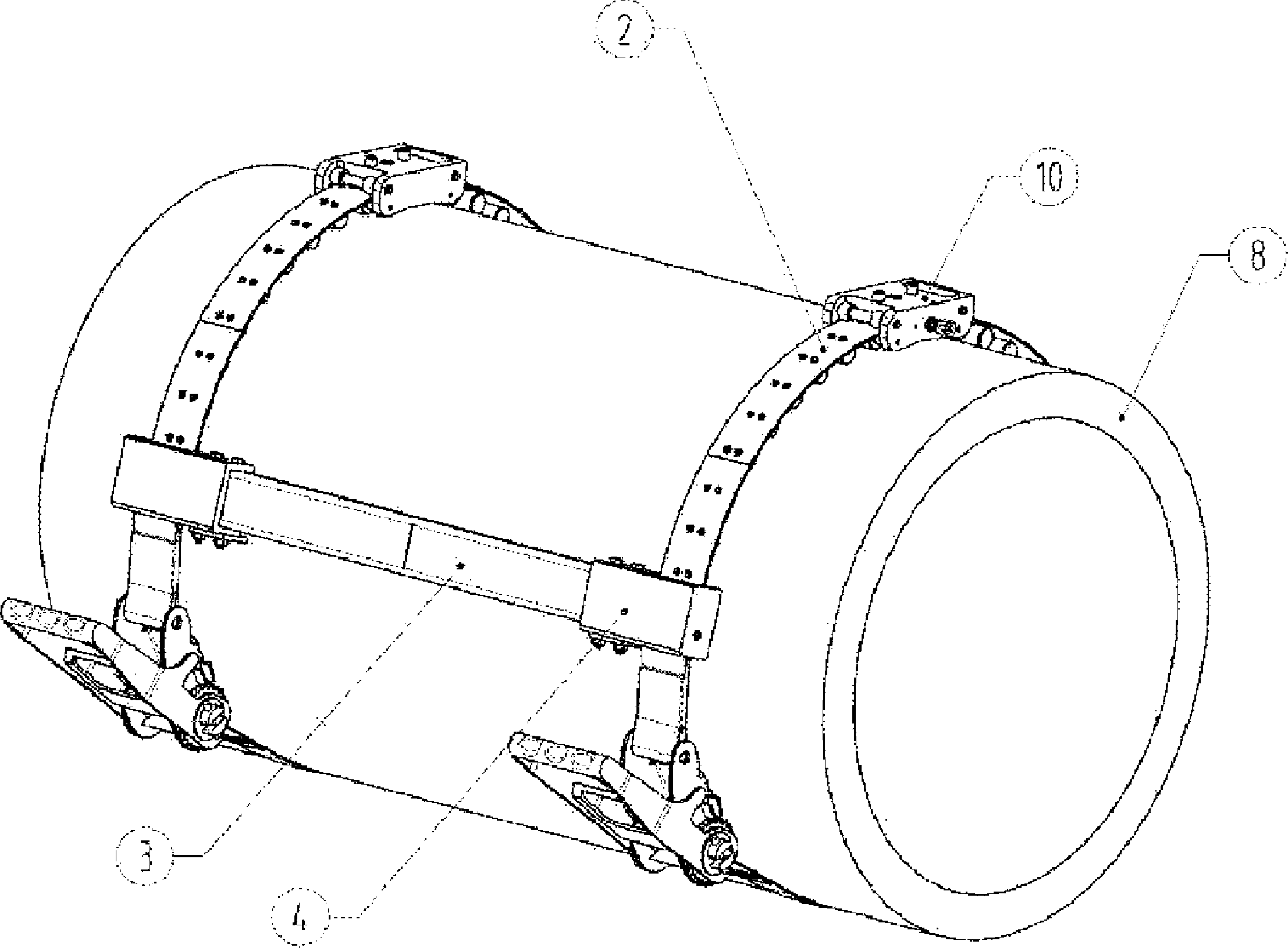

[0048] figure 1 The device according to the invention is shown mounted on a circumference. The two strips 2 , preferably of spring steel, are adapted to the extension of the circumference of the tube 8 . The material of the strips 2 is chosen such that it has a high torsional strength as well as torsional rigidity, which means that the strips 2 can hardly be deformed along their length, but they are easy to deform with a high degree of flexibility along their length Adapt to the circumference of the tube 8. By means of spacers 5 arranged on the bottom side 6 of the strip, the strip is at a constant distance from the outer circumference of said tube 8 or from its surface. The two strips 2 of the device run parallel to each other. The strip ends of two strips 2 lying on the same side of the circumference or positioned side by side are in each case connected together by means of a carrier 3 . Thus, the device 1 forms a type of frame 9 positioned on the outer circumference of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com