Novel cantilever drilling machine lifting mechanism

The technology of a cantilever drilling machine and a lifting mechanism is applied in the field of machine tools, which can solve the problems of weak resistance to the eccentric moment of the cantilever, wear or breakage of a single lead screw, and passiveness, and achieve the effect of good use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

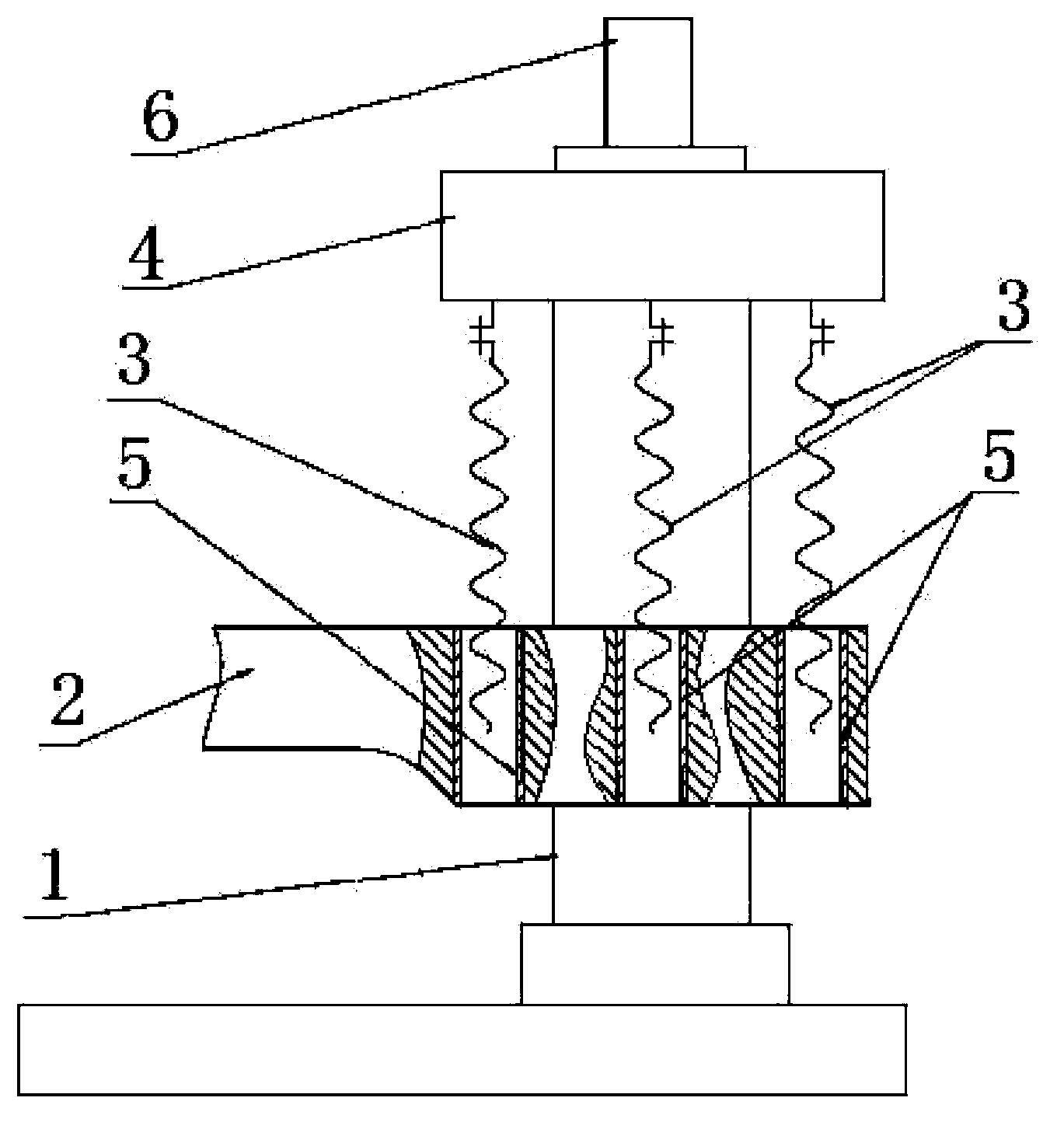

[0009] figure 1 Among them, it is composed of: column (1), cantilever (2), screw (3), reduction box (4), screw nut (5) and motor (6); it is on the column (1) of the drilling machine Three lead screws (3) coaxial with the column (1) are arranged respectively, so that the structure of the three lead screws (3) has a strong effect of resisting the eccentric moment of the cantilever (2). Therefore, the lead screw (3) Not easy to be frayed or broken.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com