Preparation method of a new type of mineral silica flake desiccant, and related desiccant

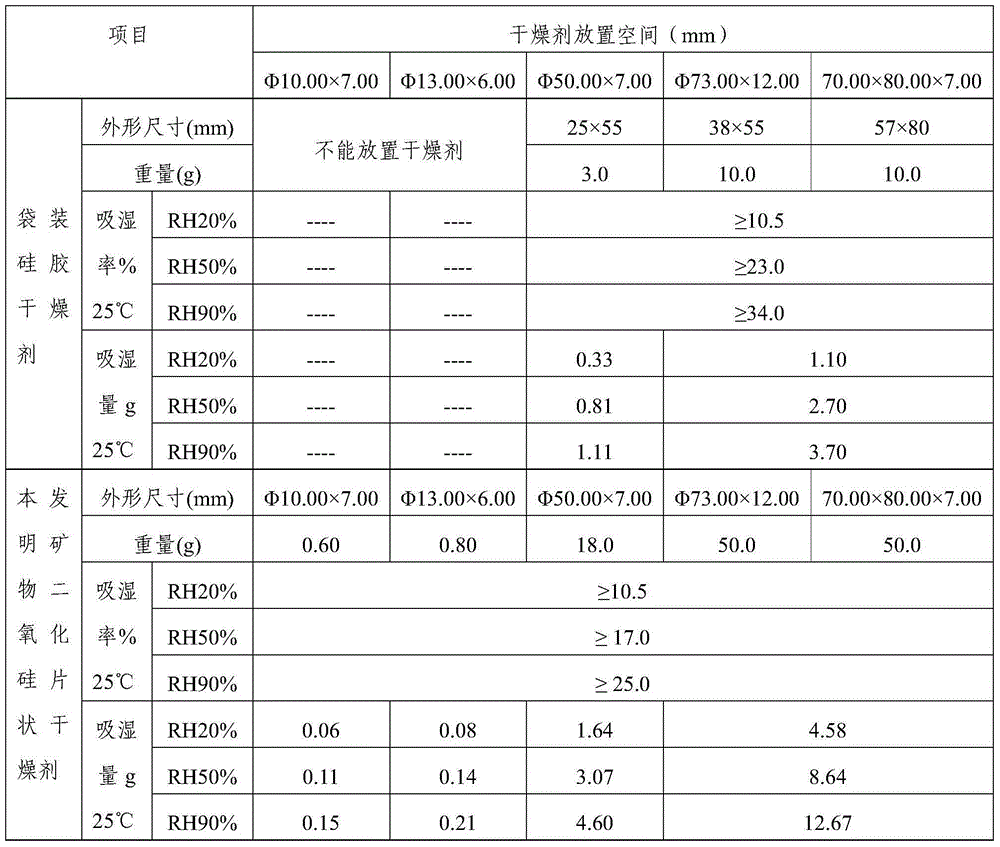

A silicon dioxide and desiccant technology, applied in the preparation of new mineral silica flake desiccant, the field of new mineral silica flake desiccant, can solve the problem that the packaging cannot be tightly fitted, and the process and space of the automation industry are limited. The problems of low dosage and other problems have achieved great application prospects and economic value, continuous automatic dosage and operation, and simple and easy preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: the preparation of mineral silica powder

[0042] Step 1: Natural Mineral Purification

[0043] Stir and soak 5 parts of montmorillonite ore soil with 80 parts of purified water for more than 50 hours, wait for it to fully expand, and sieve through 200 mesh or more to separate large particles of impurity ore soil.

[0044] Step Two: Wrap

[0045] Put 8 parts of the above-mentioned purified minerals and fine-pored (type A) silica powder (particle size above 400 mesh) into the flake machine, grind for more than 60 hours, and centrifuge the mixed material in a high-speed centrifuge (rotating speed of 2000 rpm above), remove the particles, and prepare the coating solution.

[0046] Step Three: Dry

[0047] Concentrate the prepared coating solution and dry it in vacuum to obtain mineral silica desiccant powder.

Embodiment 2

[0048] Embodiment 2: the preparation of mineral silica powder

[0049] Step 1: Natural Mineral Purification

[0050] Stir and soak 2 parts of montmorillonite ore soil and 3 parts of attapulgite clay with 100 parts of purified water for more than 50 hours, wait for them to fully expand, and then sieve through 200 mesh or more to separate large particles of impurity ore soil.

[0051] Step Two: Wrap

[0052] Put the above-mentioned purified minerals together with 3 parts of fine-pore (type A) silica gel powder (particle size: more than 400 mesh) and 2 parts of coarse-pore (type B) silica gel powder into the peeling machine, grind for more than 60 hours, and put The mixed material is centrifuged in a high-speed centrifuge (with a speed of more than 2000 rpm) to remove particulate matter and obtain a coating solution.

[0053] Step Three: Dry

[0054] Concentrate the obtained coating solution and dry it in a drying box to obtain mineral silica desiccant powder.

Embodiment 3

[0055] Embodiment 3: Preparation of mineral silica flake desiccant

[0056] Step 1: Granulation

[0057] Firstly, 5 parts of the natural mineral silica powder prepared in Example 1 were sprayed evenly and slowly into about 2 parts of purified water in the granulation pot for granulation.

[0058] Step Two: Dry

[0059] The granules obtained in the previous step are properly dried in an oven.

[0060] Step Three: Sieve

[0061] The particles dried in the previous step are sieved in a swinging machine equipped with a 1mm sieve.

[0062] Step 4: Compression molding

[0063] The granules sieved in the previous step are pressed and formed in a suitable mold with a corresponding size on a mechanical tablet forming machine.

[0064] Step Five: Activation

[0065] The granules compressed in the previous step are dried to obtain a new type of mineral silica flaky desiccant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com