Torsional oscillation attenuation device

A technology of attenuation device and torsional vibration, which is applied in the direction of vibration suppression adjustment, spring/shock absorber, mechanical equipment, etc., and can solve problems such as inability to attenuate torsional vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

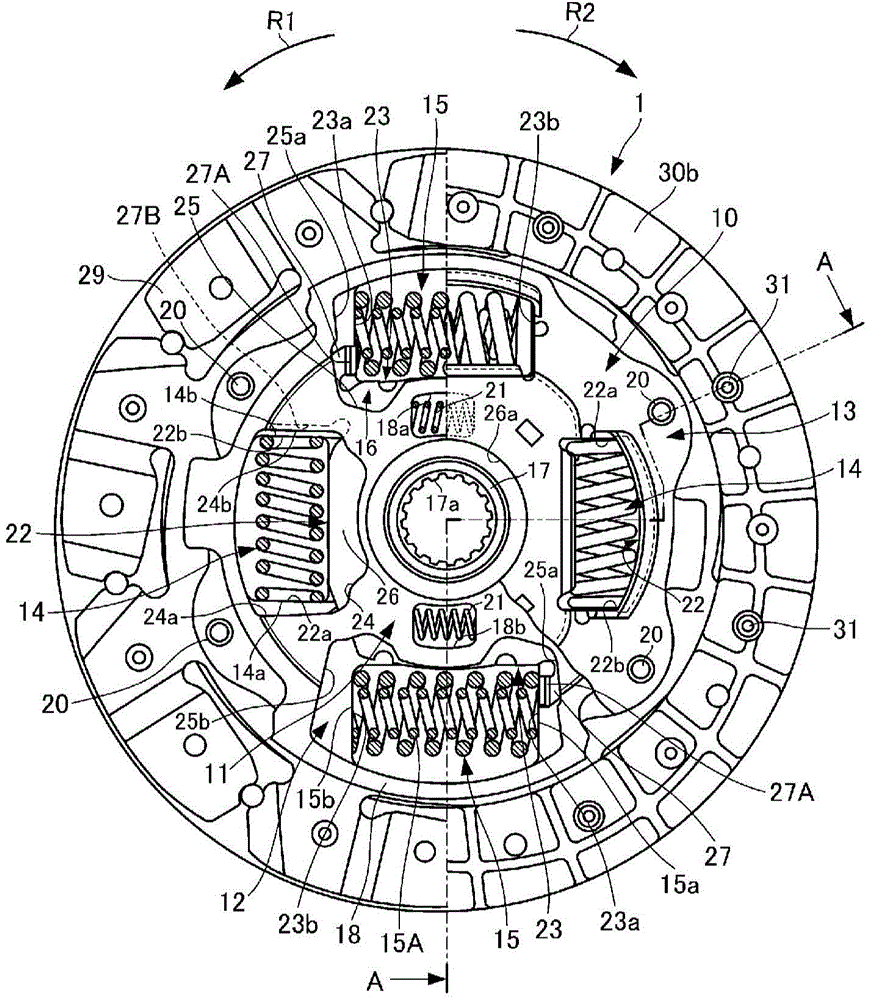

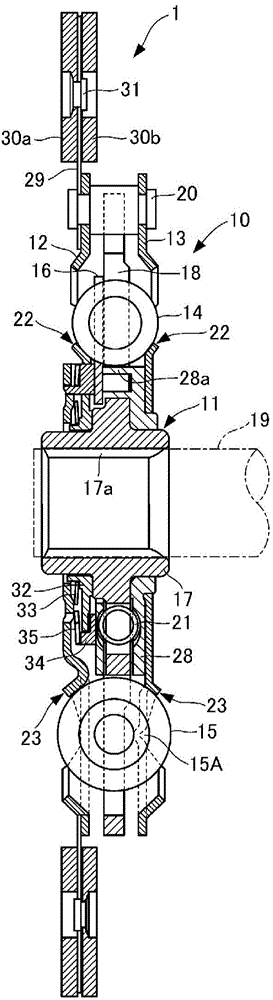

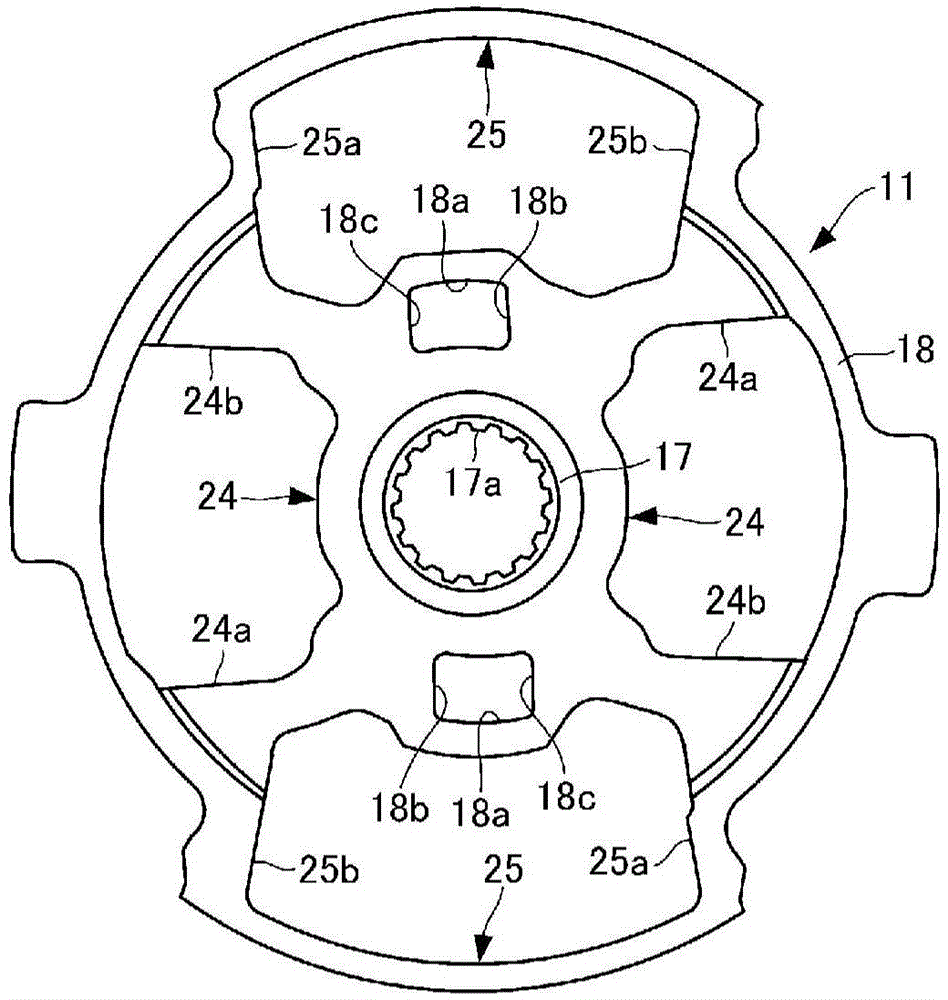

[0092] Hereinafter, embodiments of the torsional vibration damping device of the present invention will be described with reference to the drawings.

[0093] Figure 1 to Figure 21 It is a figure showing one embodiment of the torsional vibration damping device of the present invention, and an example in which the torsional vibration damping device is applied to a clutch device will be described.

[0094] First, the structure will be described.

[0095] exist figure 1 , figure 2 Among them, the clutch device 1 is equipped with a torsional vibration damping device 10, and the torsional vibration damping device 10 includes: a hub spacer 11 as a driven side rotating member; Discs 12 and 13 as drive side rotating members that can rotate freely; coil spring 14 as a first elastic member that elastically connects the hub spacer 11 and discs 12 and 13 in the direction of rotation, and a coil spring 14 as a second elastic member. the spring 15 ; the sub-plate 16 provided so as to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com