Non-wear induction speed reducing and changing machine

A variable speed, wear-free technology, applied in the field of speed reducers, can solve the problems of reducing the service life of the speed reducers, reducing the working efficiency of the speed reducers, and wasting equipment power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

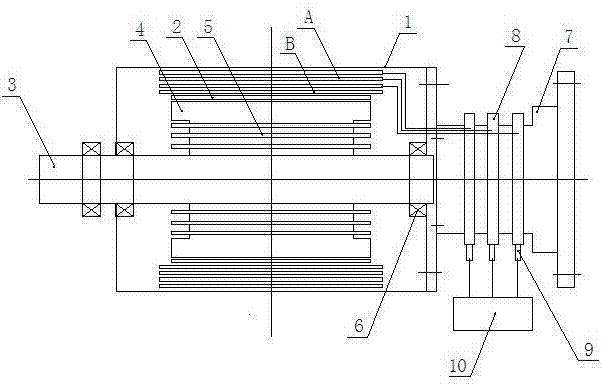

[0008] see figure 1 , the wear-free induction deceleration machine of the present invention comprises a low-speed rotating body and a high-speed rotating body placed in the low-speed rotating body, the low-speed rotating body has a cylindrical shell 1, and the inner wall of the cylindrical shell 1 is connected with a low-speed rotating body iron Core 2, low-speed rotating body core 2 is evenly distributed with low-speed rotating body induction coil A and low-speed rotating body induction coil B from outside to inside, the high-speed rotating body includes high-speed rotating body shaft 3 and connected with high-speed rotating body shaft 3 The high-speed rotating body iron core 4, the high-speed rotating body iron core 4 is evenly distributed with the high-speed rotating body induction coil 5, the high-speed rotating body 3 of the high-speed rotating body passes through the bearing 6 and the cylindrical shell 1 of the low-speed rotating body Connected, there is a gap between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com