Mobile phone motor automatic assembly production line

A production line and motor technology, applied in electromechanical devices, electric components, manufacturing motor generators, etc., can solve the problems of poor uniformity of incoming materials for product components, increasing labor demand gap, and rising production costs of micro motors, saving labor. resources, the effect of promoting process improvement and innovation, and enhancing competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

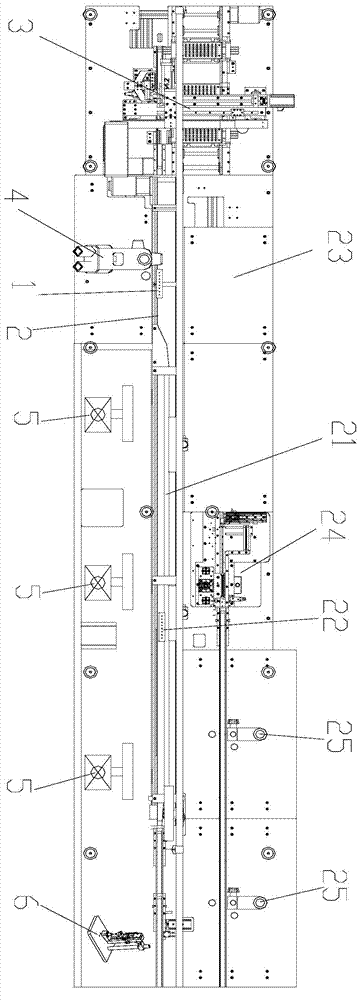

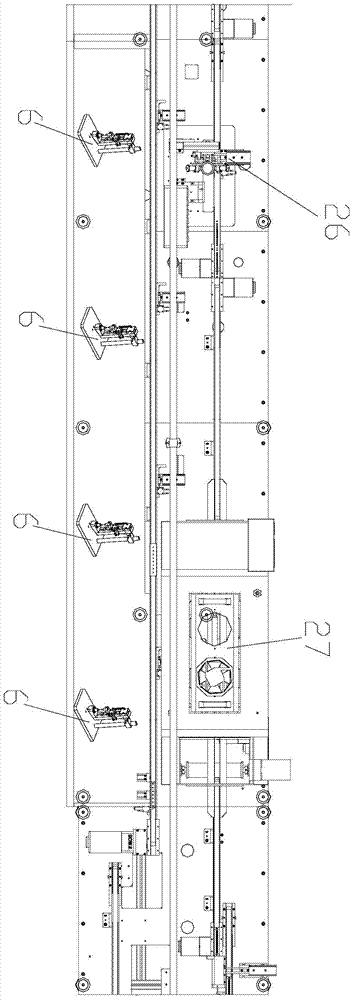

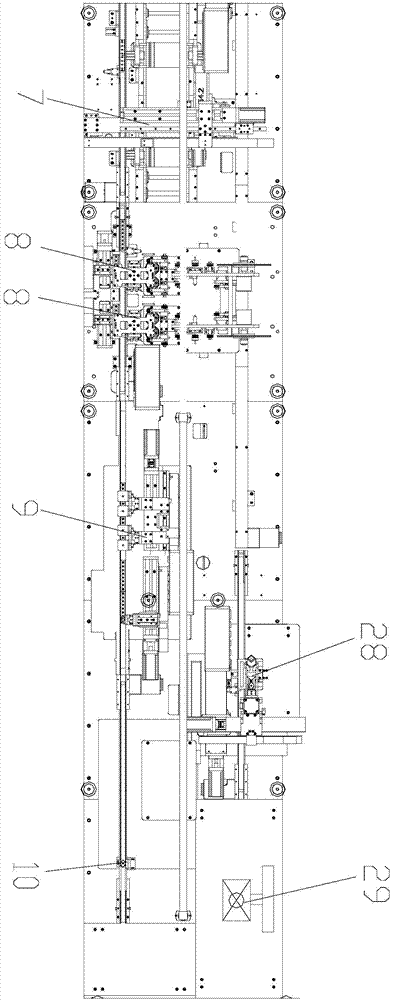

[0055] Such as figure 1 Shown is the top view of the first part of the embodiment of the mobile phone motor automatic assembly production line embodiment; as figure 2 Shown is the top view of the second part of the embodiment of the automatic assembly line for mobile phone motors of the present invention; image 3 Shown is the top view of the third part of the embodiment of the mobile phone motor automatic assembly production line embodiment; as Figure 4 Shown is the top view of the fourth part of the embodiment of the mobile phone motor automatic assembly production line embodiment; as Figure 5 Shown is the top view of the fifth part of the embodiment of the mobile phone motor automatic assembly production line embodiment; as Figure 6 Shown is the top view of the sixth part of the embodiment of the automatic assembly line for mobile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com