Bidirectional exhaust cable cooler

A cooler and air extraction technology, applied in the direction of cooling/ventilation of substations/switchgears, cooling busbar devices, etc., can solve the problems of unfavorable cooling, power consumption, low operational reliability, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

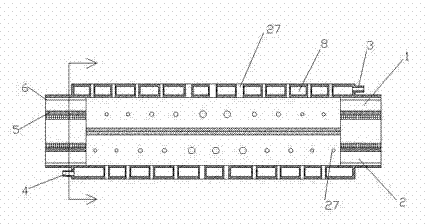

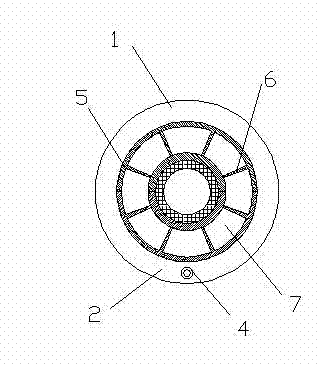

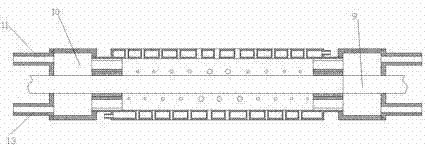

[0014] A two-way suction type cable cooler, including a main body and an air suction part 10, wherein the main body includes an upper semicircle part 1 and a lower semicircle part 2, and the upper semicircle part 1 and the lower semicircle part 2 are fastened to form a cylinder , a sealing strip is provided at the interface between the upper semicircle part 1 and the lower semicircle part 2; a cylindrical coolant barrier layer is provided on the outer peripheral surface of the cylinder, and the interior of the cylinder has a 9, the cylindrical coolant barrier layer surrounds the cavity, and the upper right end of the cylindrical coolant barrier layer is fluidly connected with a liquid inlet 3, and the lower left end is fluidly connected with a liquid outlet 4. The cylindrical cooling liquid barrier layer is also provided with a circular air hole 27, and the inner peripheral side wall of the circular air hole 27 can seal the circular air hole 27 and the inner cavity of the cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com