Determination method and application of hydrogen sulfide content in methanol solution

A technology of methanol solution and determination method, which is applied in the direction of color/spectral characteristic measurement, etc., can solve problems such as difficulty in popularization and use, expensive instruments and equipment, etc., and achieve the effect of ensuring absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

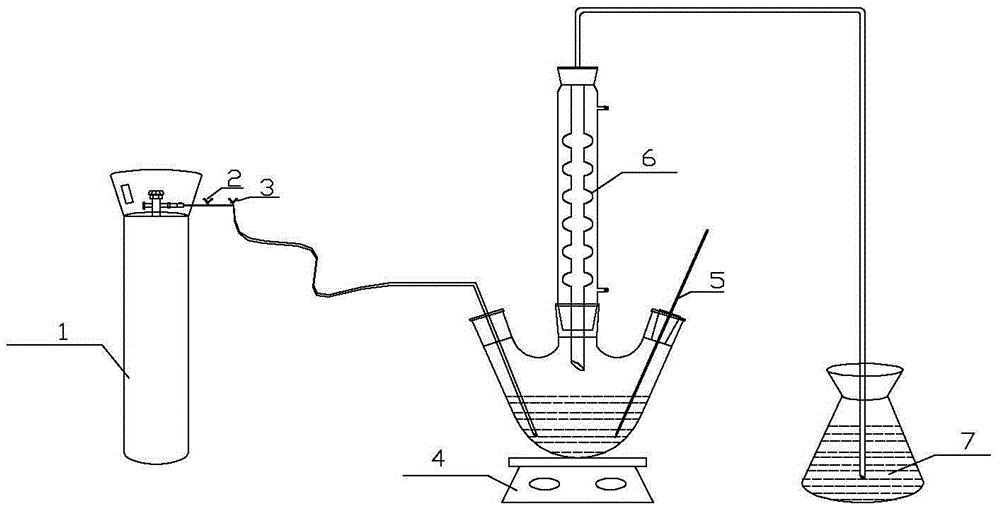

Method used

Image

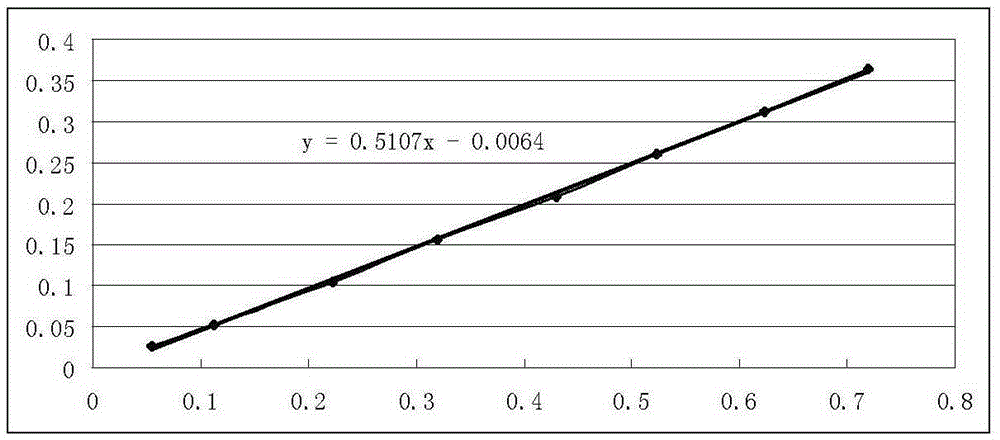

Examples

Embodiment 1

[0036] A. Preparation of detection reagents:

[0037] a. Deionized water deoxygenation: pass distilled water through an ion exchange column to obtain deionized water, and pass nitrogen gas (purity > 99.99%) to saturation to remove dissolved oxygen in the water. The water used in this experiment was double distilled water.

[0038] b. Prepare p-aminodimethylaniline solution: weigh 2g of p-aminodimethylaniline hydrochloride [NH 2 C 6 h 4 N(CH 3 ) 2 ·2HCl] dissolved in 200mL of water, slowly add 200mL of concentrated sulfuric acid, dilute to 1000mL with water after cooling, shake well, the concentration is 2g / L.

[0039] c. Prepare ferric ammonium sulfate solution: weigh 2.5g of ferric ammonium sulfate [Fe(NH 4 )(SO 4 ) 2 12H 2 O], dissolve in water containing 5mL of concentrated sulfuric acid, dilute to 250mL with water, shake well, the concentration is 10g / L.

[0040] d. Preparation of zinc acetate-sodium acetate solution: weigh 50g of zinc acetate (ZnAc 2 2H 2 O) a...

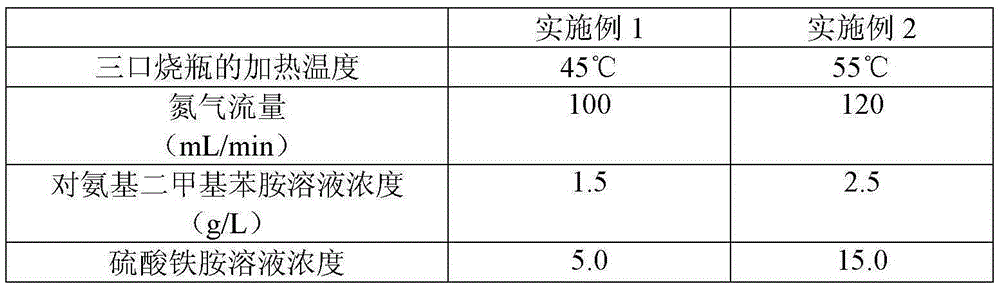

Embodiment 2

[0056] Wherein the steps of A, B, and C are the same as in Example 1, except that the specific conditions in step D, such as the heating temperature of the three-necked flask, the amount of raw materials added, and the nitrogen flow rate, etc., are specifically shown in Table 2.

[0057] The methanol solution to be tested used in Examples 1-2 is 200 mL of regenerated methanol solution in the "low temperature methanol washing" section of Shaanxi Shenmu Chemical Industry Co., Ltd.

[0058] In order to further verify the accuracy of the present invention's method for measuring hydrogen sulfide content in methanol solution, take respectively 200mL of regenerated methanol solution in the "low temperature methanol washing" section in Example 1 and Example 2, respectively adopt the assay method of the present invention, total sulfur analysis The content of hydrogen sulfide in the regenerated methanol solution was determined by the instrumental method, and the results were compared, se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com