Detection system, detection method and adjustment method for uniformity of cutting edge of printing scraper

A detection system and detection method technology, applied in electromagnetic measurement devices, electric/magnetic roughness/irregularity measurement, etc., can solve problems such as hidden product quality hazards and uncontrolled scraper uniformity, and achieve rapid analysis, response and improvement. Printing production efficiency and printing quality, and the effect of preventing abnormality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0030] Any feature disclosed in this specification (including any appended claims, abstract and drawings), unless expressly stated otherwise, may be replaced by alternative features which are equivalent or serve a similar purpose. That is, unless expressly stated otherwise, each feature is one example only of a series of equivalent or similar features.

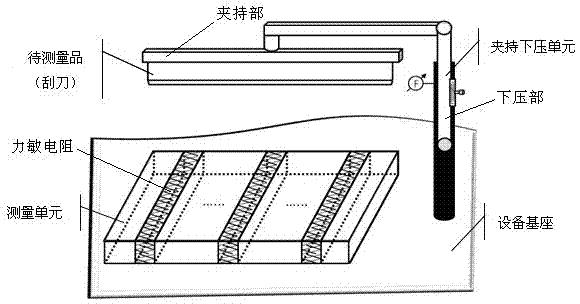

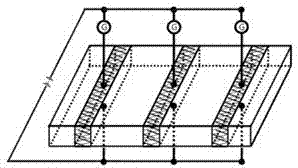

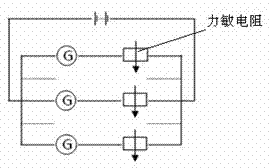

[0031] In order to monitor the uniformity of the squeegee edge to improve the printing quality, the invention provides a detection system, detection method and adjustment method for quickly detecting the uniformity of the squeegee. The detection da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com