Installation structure of jointless conductive nickel ring

A technology of installation structure and nickel ring, which is applied in the direction of furnace, heat treatment equipment, heat treatment furnace, etc., can solve problems such as easy shaking, unguaranteed outer circle size, scrapped nickel ring, etc., to improve work reliability and quality of outlet , The effect of simplifying the structure of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

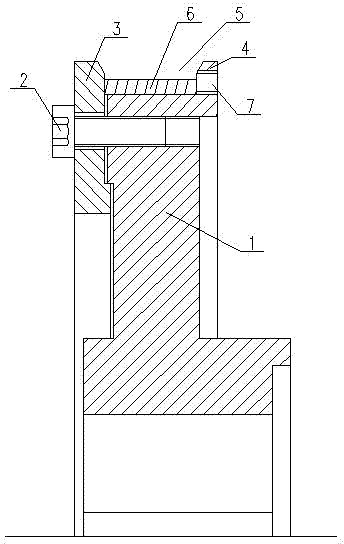

[0009] like figure 1 As shown, the installation structure of the non-interface conductive nickel ring includes: a contact copper wheel 1, a contact wheel cover 3 connected to the contact copper wheel 1 through a connecting screw 2, and the contact wheel 4 on the outer edge 4 of the contact copper wheel 1. A wiring groove 5 is formed between the outer sides of the wheel cover 3, and there is a non-interface conductive nickel ring 6 in the wiring groove 5 outside the contact copper wheel 1, and the two ends of the non-interface conductive nickel ring 6 are connected to the contact wheel cover 3 respectively. The outer side and the outer edge 4 of the contact copper wheel 1 are offset, and some disassembly process screw holes 7 are arranged on the outer edge 4 of the contact copper wheel 1.

[0010] When the above-mentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com