Method for preparing tetrapod-like zinc oxide nanorod

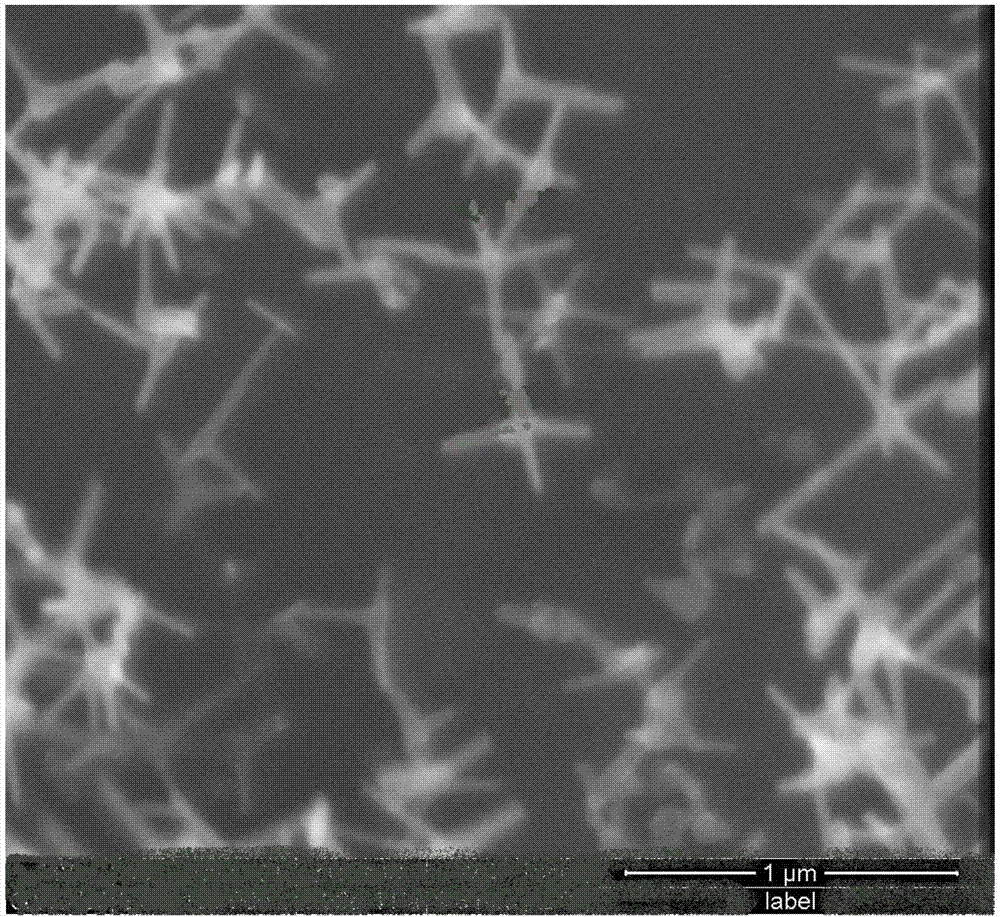

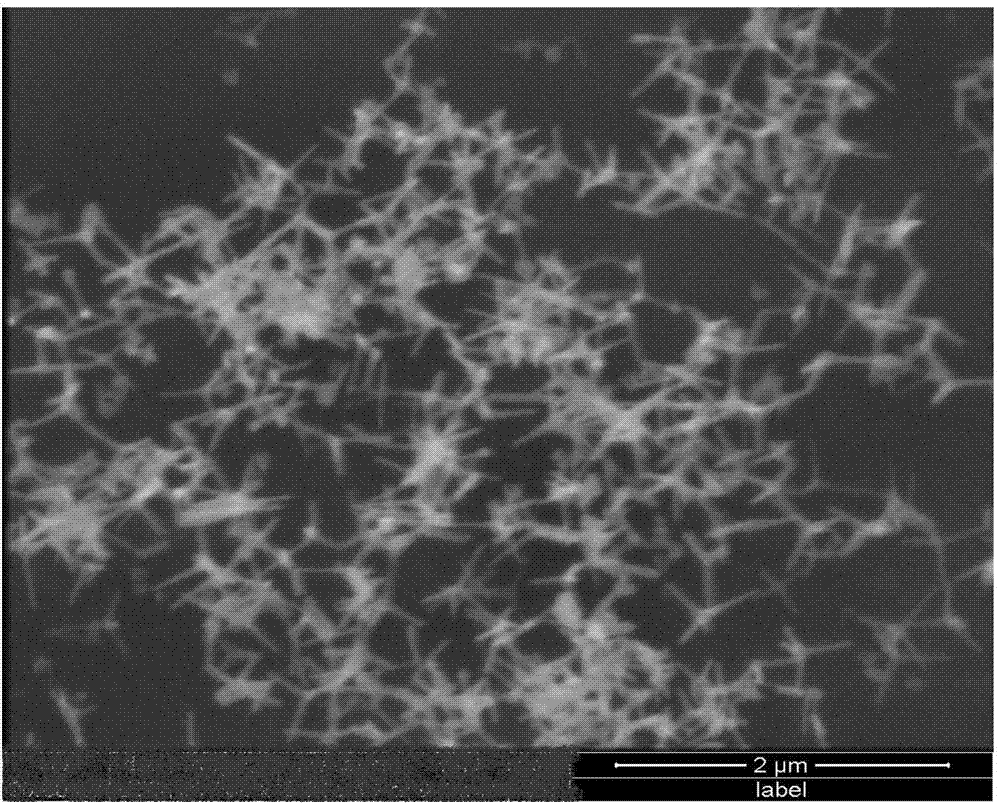

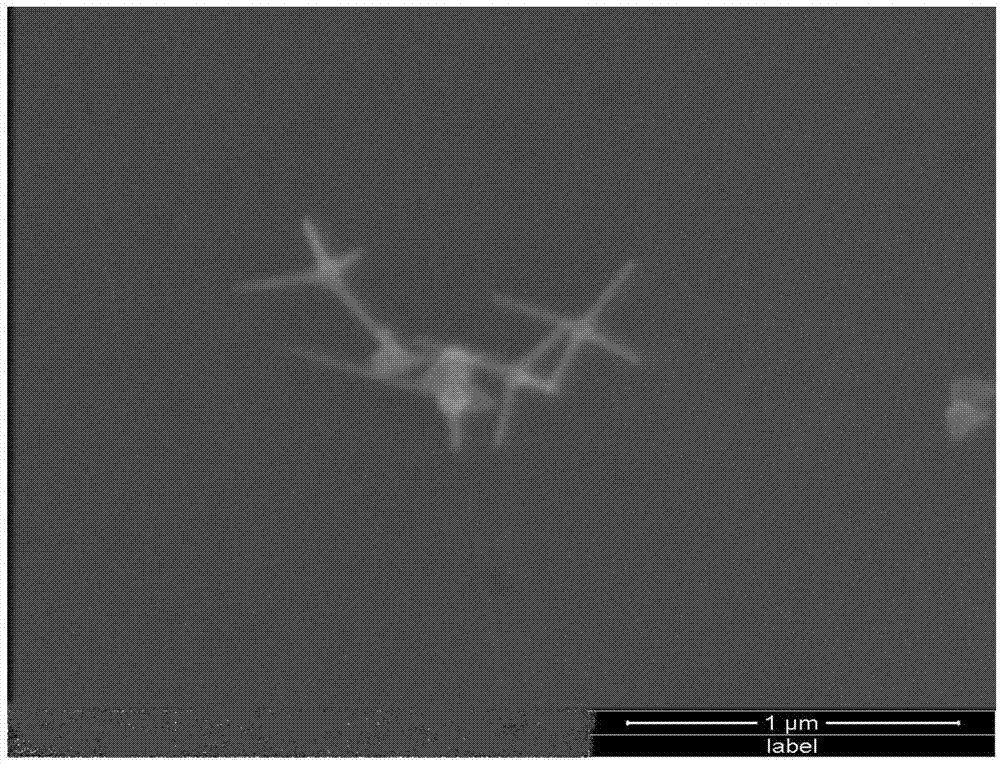

A four-needle zinc oxide and nanorod technology, which is applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of large size and low purity of nanorods, and achieve simple operation, high purity and high product quality. The effect of size and shape stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Shred zinc foil with a purity >99.9% and clean it ultrasonically, fill it in one end of a small quartz tube (6) with an inner diameter of 5 mm and leave a gap, and plug the other end with refractory asbestos (9) and leave a gap; then fill it Put the small quartz tube (6) of crushed zinc foil (8) in the porcelain boat; put the porcelain boat (7) into the middle and rear part of the large quartz tube (3) with an inner diameter of 30mm in the tube resistance furnace, and the large quartz tube (3) Three hole plugs are required at the open end, which are nitrogen inlet, oxygen inlet and tail gas outlet respectively. Use a flow meter to adjust the total flow of nitrogen and oxygen into the large quartz tube (3) to be 20 sccm. The nitrogen tube mouth directly passes into the bottom of the large quartz tube (3). Continue to feed nitrogen after it is empty; the oxygen nozzle is placed in the middle of the large quartz tube (3). Oxygen is fed in at a rate of 5% by volume. The ox...

Embodiment 2

[0030] Shred the zinc foil with a purity >99.9% and clean it ultrasonically, fill it in one end of a small quartz tube (6) with an inner diameter of 13mm and leave a gap, and plug the other end with refractory asbestos (9) and leave a gap; then fill it Put the small quartz tube (6) of crushed zinc foil (8) in the porcelain boat, and set the inclination angle of 45°; put the porcelain boat (7) into the large quartz tube (3) with an inner diameter of 65mm in the tubular resistance furnace The opening end of the large quartz tube (3) is required to be provided with three-hole plugs, which are nitrogen inlet, ozone inlet, and exhaust gas outlet. Use a flow meter to adjust the total flow of nitrogen and ozone into the large quartz tube (3) to be 350 sccm. The nitrogen tube mouth directly passes into the bottom of the large quartz tube (3). Continue to feed nitrogen after it is empty; the ozone nozzle is placed in the middle of the large quartz tube. Ozone is introduced at a ratio ...

Embodiment 3

[0032]Shred the zinc foil with a purity >99.9% and clean it ultrasonically, fill it in one end of a small quartz tube (6) with an inner diameter of 20mm and leave a gap, and plug the other end with refractory asbestos (9) and leave a gap; then fill it Put the small quartz tube (6) of broken zinc foil (8) in the porcelain boat, and set the inclination angle of 20°; put the porcelain boat (7) into the large quartz tube (3) with an inner diameter of 100mm in the tubular resistance furnace At the rear, the open end of the large quartz tube (3) requires three-hole plugs, which are nitrogen inlet, oxygen inlet, and exhaust gas outlet. Use a flow meter to adjust the total flow of nitrogen and oxygen into the large quartz tube (3) to 200 sccm. The nitrogen tube mouth directly passes into the bottom of the large quartz tube (3). Continue to feed nitrogen after it is empty; the oxygen nozzle is placed in the middle of the large quartz tube (3). Oxygen is introduced at a ratio of 40% by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com