A wheeled motor vehicle

An obstacle-breaking vehicle and maneuvering technology, applied in hoisting devices, hoisting devices, etc., can solve problems such as poor self-maneuvering ability, lack of slewing mechanism, and unsuitability for disaster rescue, so as to improve operating efficiency and avoid time delays Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with specific embodiments of the drawings, which are explanations of the present invention rather than limitations.

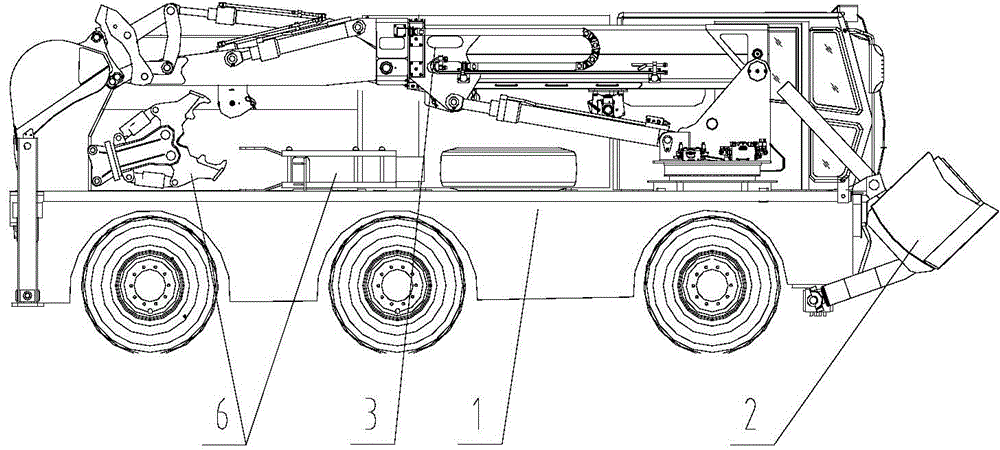

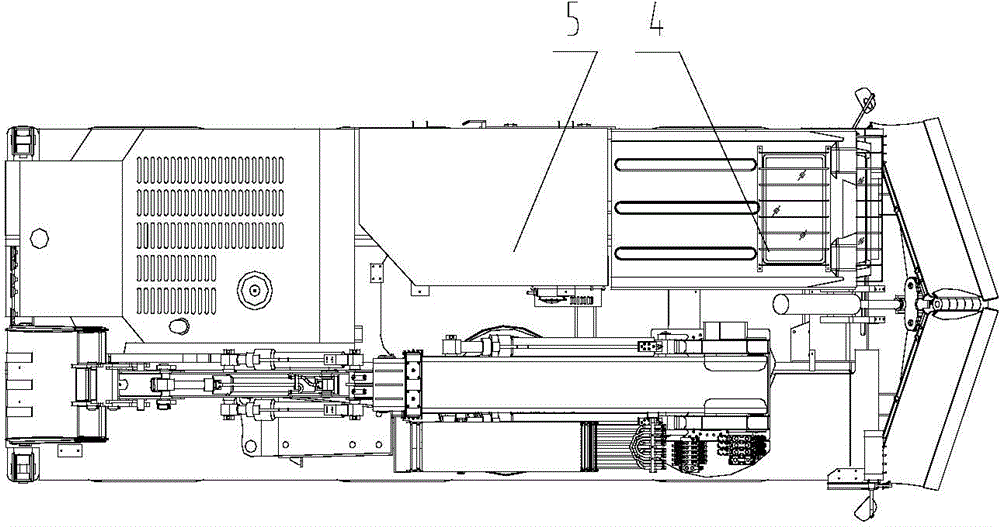

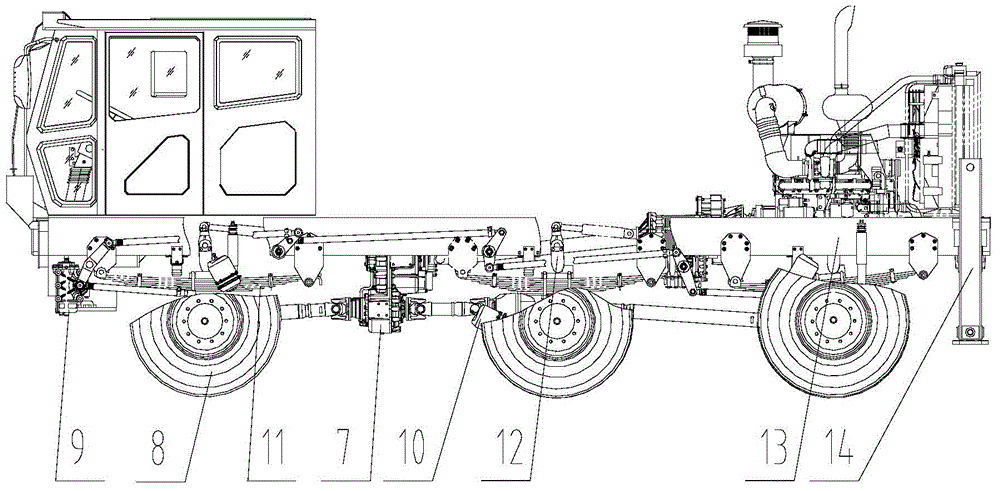

[0033] Such as figure 1 , 2 As shown, the wheeled motorized obstacle breaking vehicle includes a cab 4 and a motorized chassis 1, on which a telescopic boom arm compound operating mechanism 3 and a push-shoveling device 2 are arranged. The telescopic boom arm compound operating mechanism 3 is located above the side of the motorized driving chassis 1, and various operating attachments 6 are fixed between the telescopic boom arm and arm compound operating mechanism 3 and the motorized driving chassis 1. The rear is provided with a portable machine tool cabin 5, and the manual tools in the portable tool cabin 5 can also be used in the narrow space where the machine cannot be deployed, which greatly expands the use function of the machine, saves time for natural disaster rescue, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap