Self-locking tool quick change device

An exchange device and self-locking technology, which is applied in the field of self-locking tool rapid exchange device, can solve the problems of high failure rate, long tool change time, and large space occupation, so as to achieve less failure, short exchange time and small space occupation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

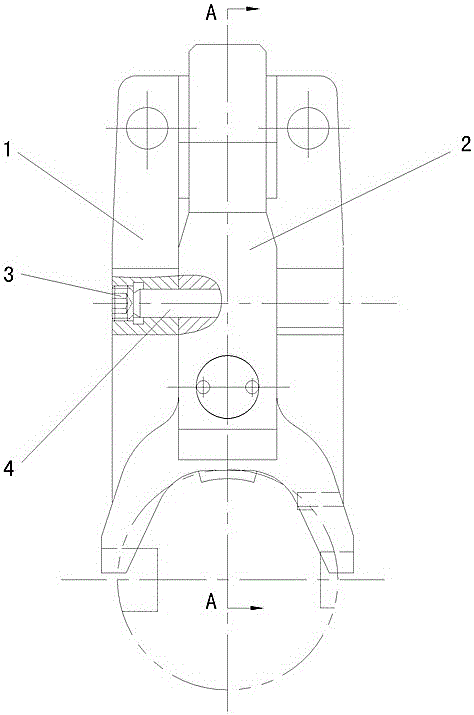

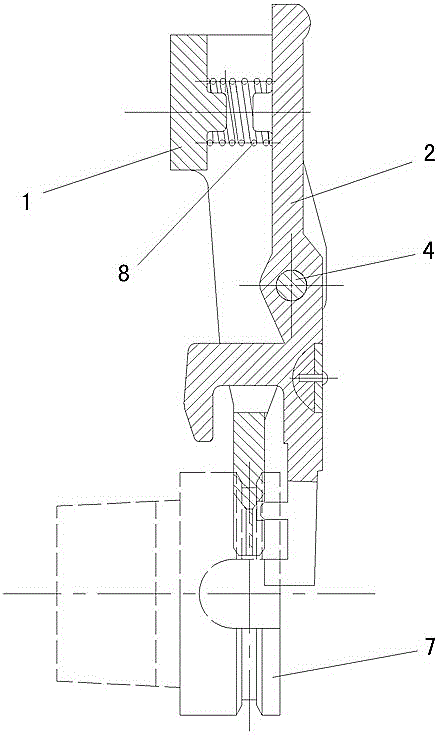

[0016] Such as figure 1 , 2 Shown: 1 is the fixed claw, 2 is the movable claw. The middle part of the fixed claw 1 and the movable claw 2 is rotationally connected by a pin shaft 4. The specific connection method is that there are symmetrical fixed claw pin holes 14 on both sides of the middle part of the fixed claw 1, and there are movable claw pin holes 26 in the middle of the movable claw 2, and the movable claw 2 Located in the middle, the pin shaft 4 is inserted in the pin hole 14 of the fixed claw and the pin hole 26 of the movable claw, and the end is equipped with an axially limited jacking screw 3 that is also threaded with the fixed claw 1, so that the movable claw 2 can be fixed relative to the fixed claw. The claw 1 rotates at a certain angle.

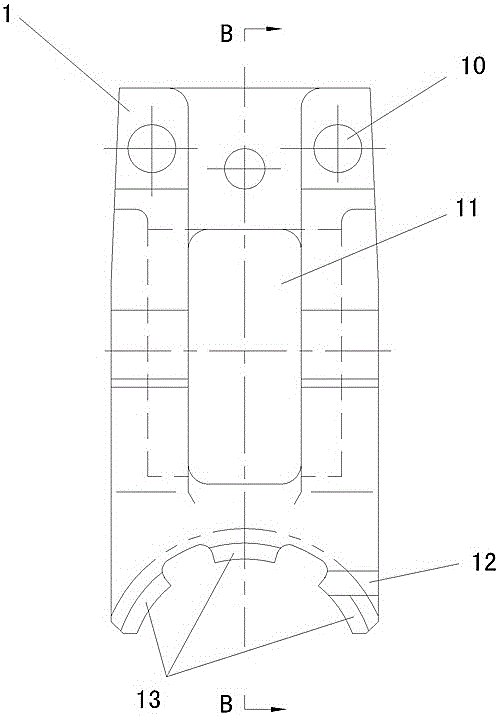

[0017] Such as image 3 , 4 , Shown in 5: a first spring abutment 15 is arranged at one end of the fixed claw 1. The other end of the fixed claw 1 is arc-shaped fork and has a protrusion 13 matching the groove on the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com