Side bending prevention device of truss welding production line

A welding production line and anti-bending technology, which is applied in the direction of auxiliary devices, welding equipment, welding equipment, etc., can solve problems such as truss deformation, truss side bending, and aggravation, so as to prevent steel bar side bending, reduce labor intensity, and save production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

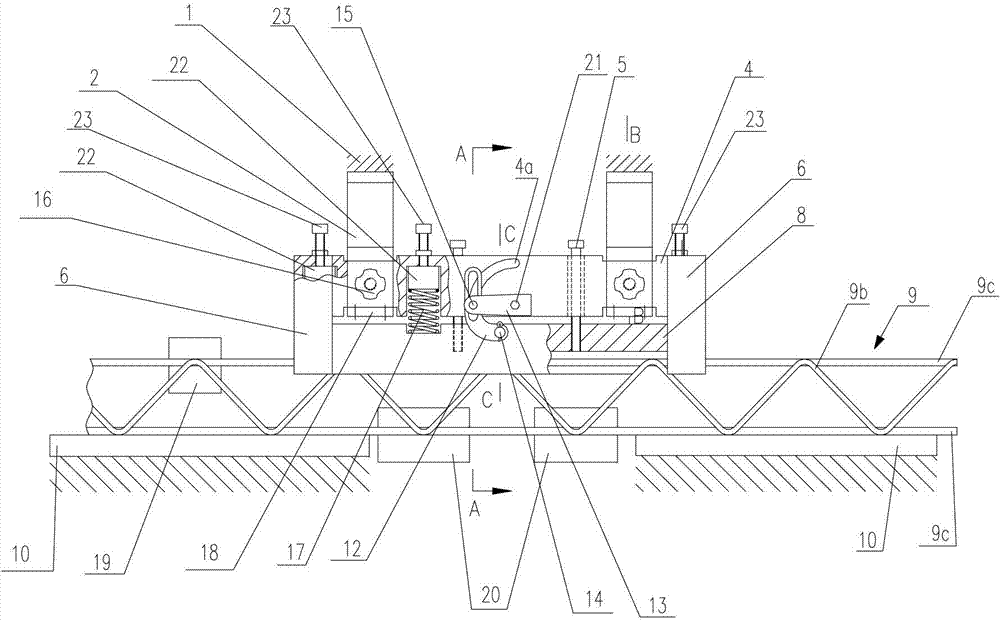

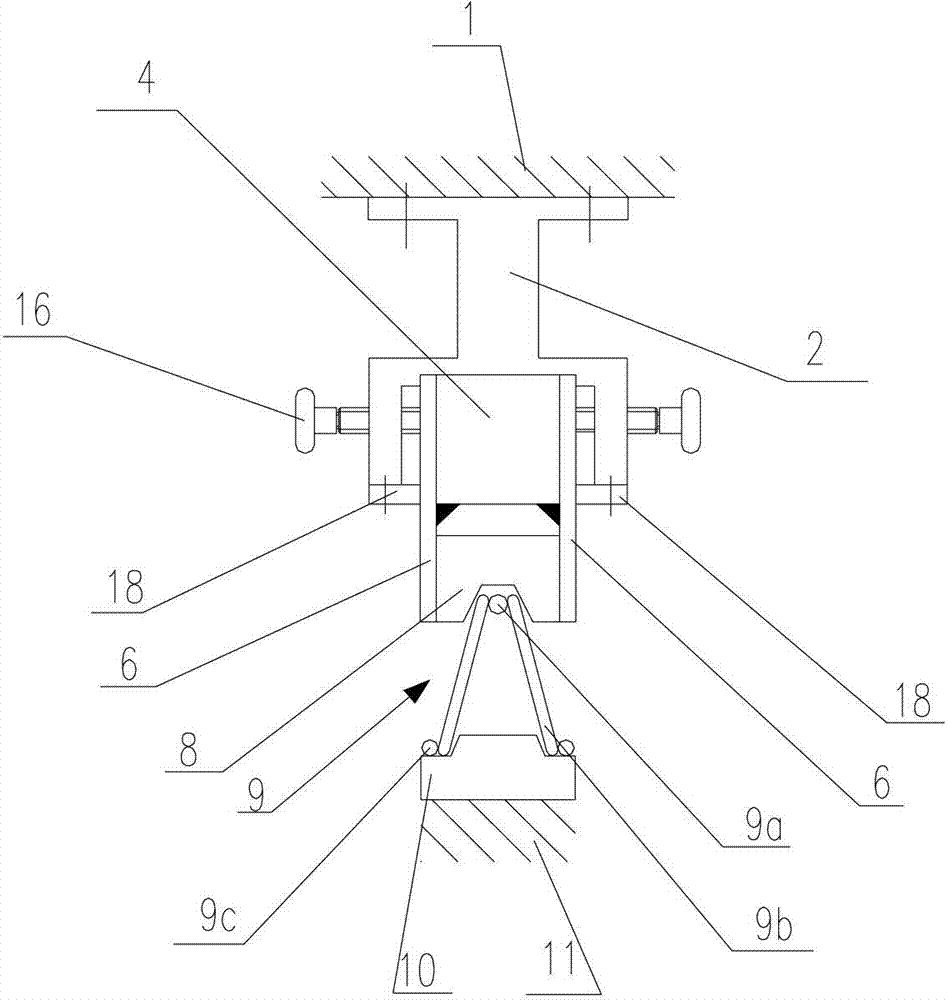

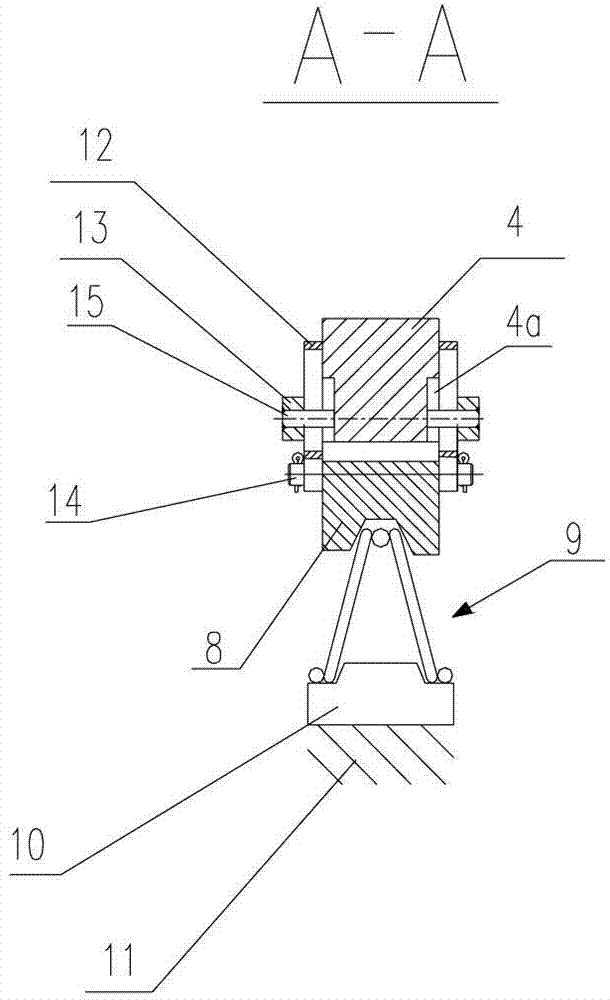

[0018] figure 1 is the front view of the present invention; figure 2 Yes figure 1 left view of image 3 Yes figure 1 A-A sectional view in ; Figure 4 Yes figure 1 Middle C-C sectional view; Figure 5 Yes figure 1 The B-B section diagram.

[0019] The truss 9 in the present invention is welded on both sides of an upper spiral 9a by the top of two zigzag webs 9b, and the bottoms of the two zigzag webs 9b are respectively welded on two lower spirals 9c.

[0020] The anti-side bending device of a truss welding production line provided by the present invention is located above the lower welding electrode 20 on the side of the upper welding electrode 19 of the truss welding production line. The structure of the anti-bending device of the present invention includes: a trapezoidal groove 8a is arranged at the bottom of a strip-shaped anti-bending te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com