Knitting machine with mutually differentiated control channels for the needles

A circular knitting machine, group control technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve problems such as needle and sinker damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

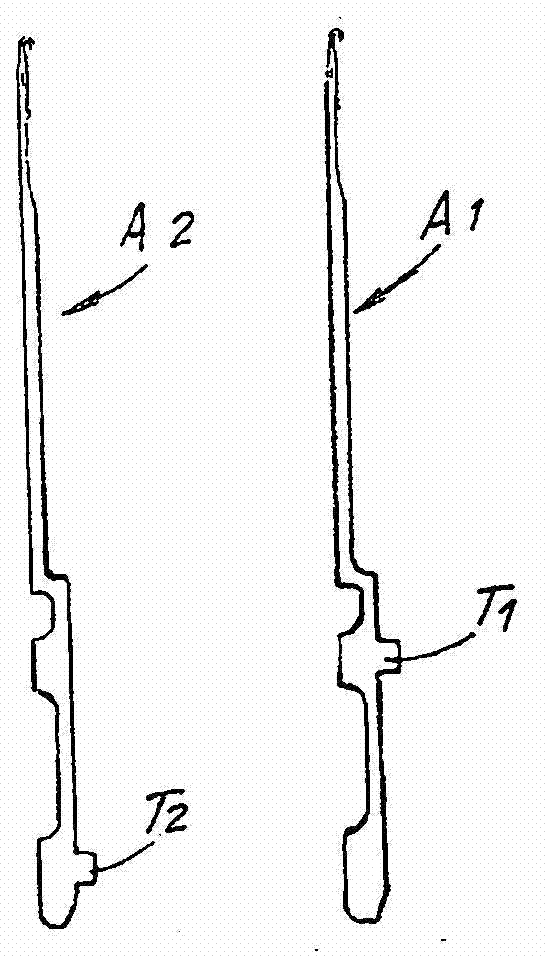

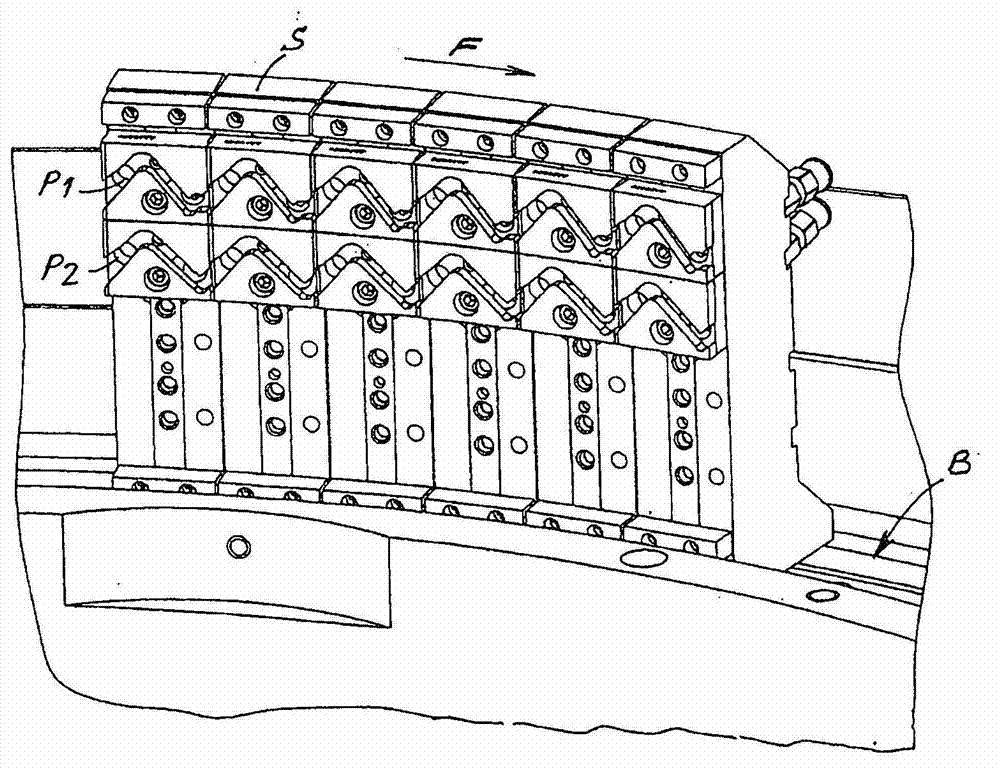

[0025] The overall structure of the knitting machine implemented by the present invention basically corresponds to the conventional machine, and it is figure 1 and 2 shown in and have been described in the previous part of the present invention.

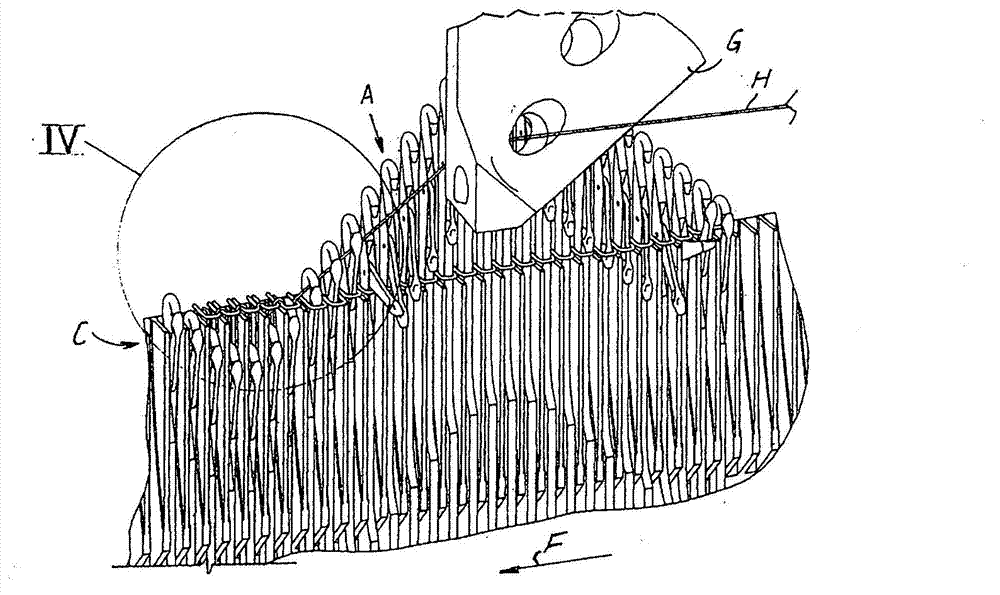

[0026] Figure 6 The front side shows the cams used by the machine according to the invention instead of the traditional ones. More specifically, there are different types of triangles according to the invention: hereinafter referred to as "type A triangles" ( Figure 6 ) triangle defines the first needle track P1 ( figure 2 ), the triangle hereinafter referred to as "R-shaped triangle" defines the second needle path P2. exist Figure 6 Also shown in is a third type of cam, called "N-type cam", used in known machines for both needle tracks P1 and P2. still in Figure 6 Among them, F represents the rotation direction of the needle cylinder, and the vertical lines LA, LR, and LN correspond to the lowest points of the descending...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com