Taste-modified type smoke-free tobacco product and manufacturing method thereof

An improved technology for smokeless tobacco, applied in tobacco, tobacco processing, application, etc., can solve problems such as difficult to retain cigarette aftertaste, strength, strong irritation, uneven release, etc., to reduce the spicy taste and irritation , weaken the stimulation, improve the effect of sensory quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

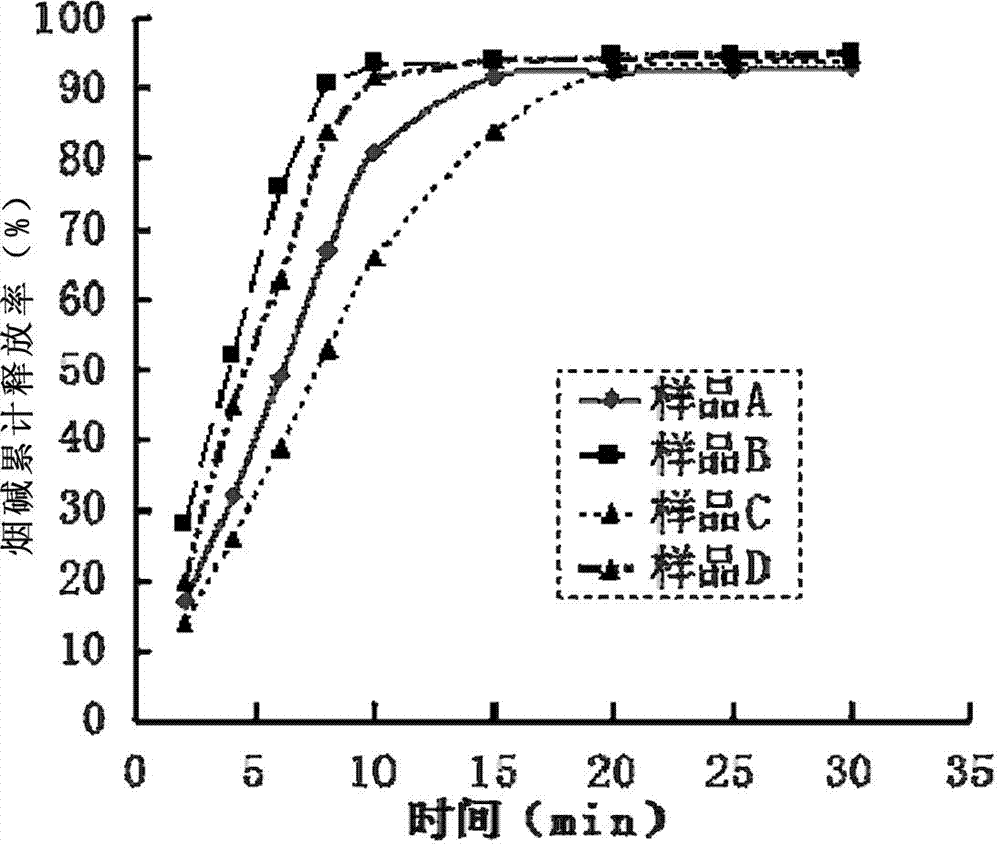

[0045]Example 1: Take the tobacco raw material and place it in an oven at 60°C, take it out when the moisture is 8% after drying, crush and sieve, keep the sieve between 60 mesh and 100 mesh, and weigh and mix evenly according to the formula ratio; then Wrap the tobacco powder with 150-200-mesh fine-pore material, put it into 4 times the weight of water, and soak it in water for 3 minutes; press filter the smoke powder after water extraction to a moisture content of 25%, and add the formula weight 2 % flavoring agent (salt with calcium gluconate and potassium iodide added) and 1% sweetener (sucrose and aspartame), and at a temperature of 75 ° C, wet heat treatment for 2 hours; After the tobacco material is carried out moisture adjustment, the moisture content after adjustment is 45%; Then, in the material after moisture adjustment, add and account for the sodium bicarbonate of formula gross weight 2% and mix homogeneously as acid-base regulator; Add 5% of the sustained-release...

Embodiment 2

[0046] Example 2: Take the tobacco raw material and put it in an oven at 60-65°C, take it out after drying until the moisture reaches 10%, crush and sieve, keep the sieve between 40 mesh and 100 mesh, and weigh and mix evenly according to the formula ratio ; Then wrap the tobacco powder with 150-200-mesh fine-pore material, put it into 7 times the weight of water, soak in water and extract it for 11 minutes; filter the smoke powder after water extraction to a moisture content of 30%, and add the formula 5% flavoring agent (riboflavin added salt) and 6% sweetener (honey and maltitol) by weight, and under the condition of 85 ℃, wet heat treatment for 4 hours; Tobacco material is carried out moisture adjustment, and the moisture content after adjustment is 30%; Then, in the material after moisture adjustment, add and account for the sodium carbonate of formula gross weight 3% as acid-base regulator and mix homogeneously; After acid-base adjustment, tobacco Add the sustained-relea...

Embodiment 3

[0047] Example 3: Take the tobacco raw material and place it in an oven at 65°C, take it out after drying until the moisture is 9%, crush and sieve, keep the sieve between 10 mesh and 100 mesh, and weigh and mix evenly according to the formula ratio; then Wrap the tobacco powder with 150-200-mesh fine-pore material, put it into 10 times the weight of water, soak in water for 15 minutes; press filter the tobacco powder after water extraction to a moisture content of 50%, and add 6% of the weight of the formula flavoring agent (edible refined salt) and 9% sweetener (brown sugar), and at a temperature of 90°C, heat-humid treatment for 5 hours; the moisture content of the tobacco material after the heat-humid treatment was adjusted, and the moisture content after adjustment 55%; then, in the material after moisture adjustment, add sodium carbonate accounting for 4% of the total weight of the formula as an acid-base regulator and mix uniformly; add 2% of its total weight in the toba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Broken particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com