Wind power plant

A ring-shaped, pontoon technology, applied in wind power generation, wind engines, wind engines at right angles to the wind direction, etc., can solve the problem that wind power stations cannot be installed in deep-water shelf areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

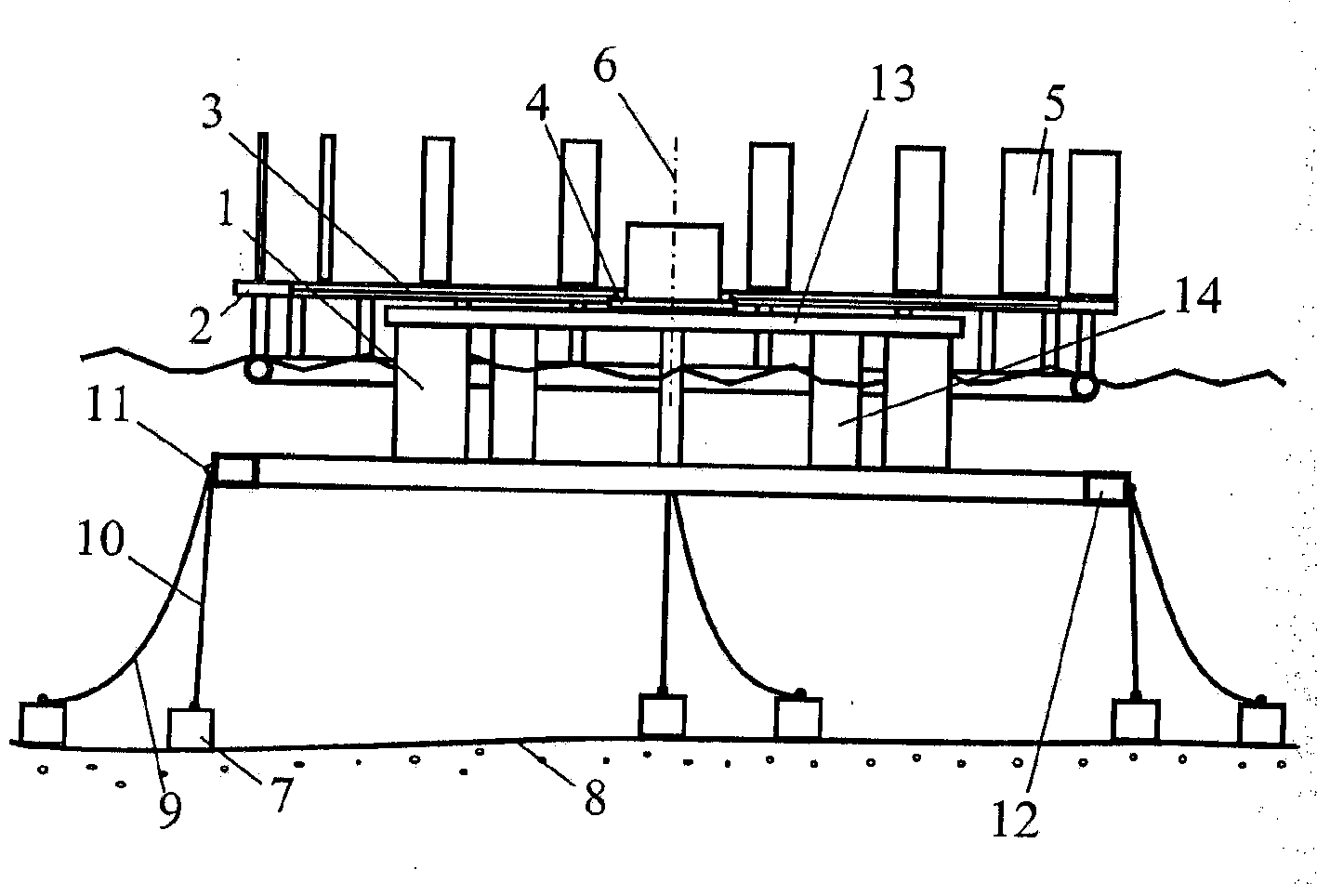

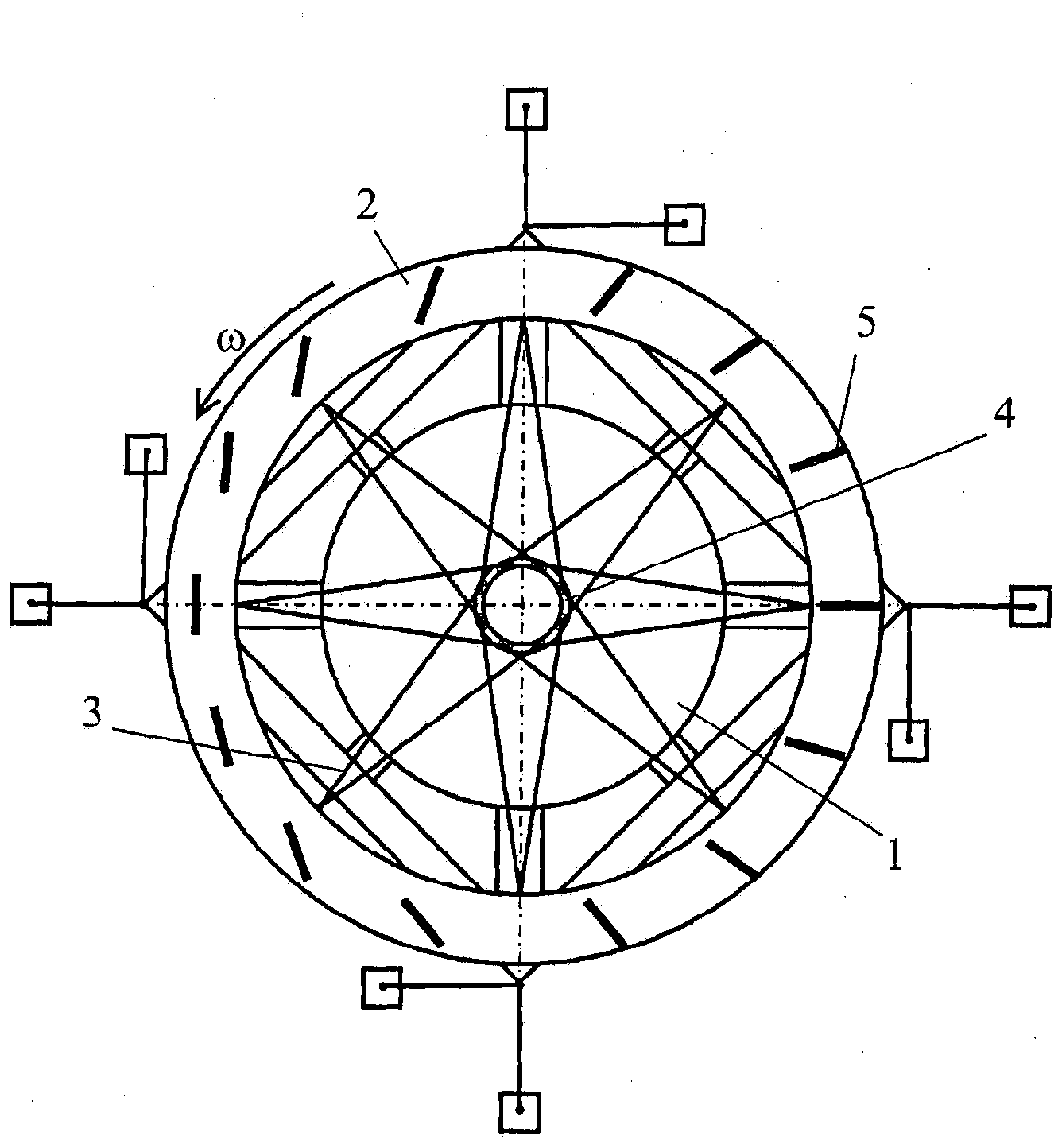

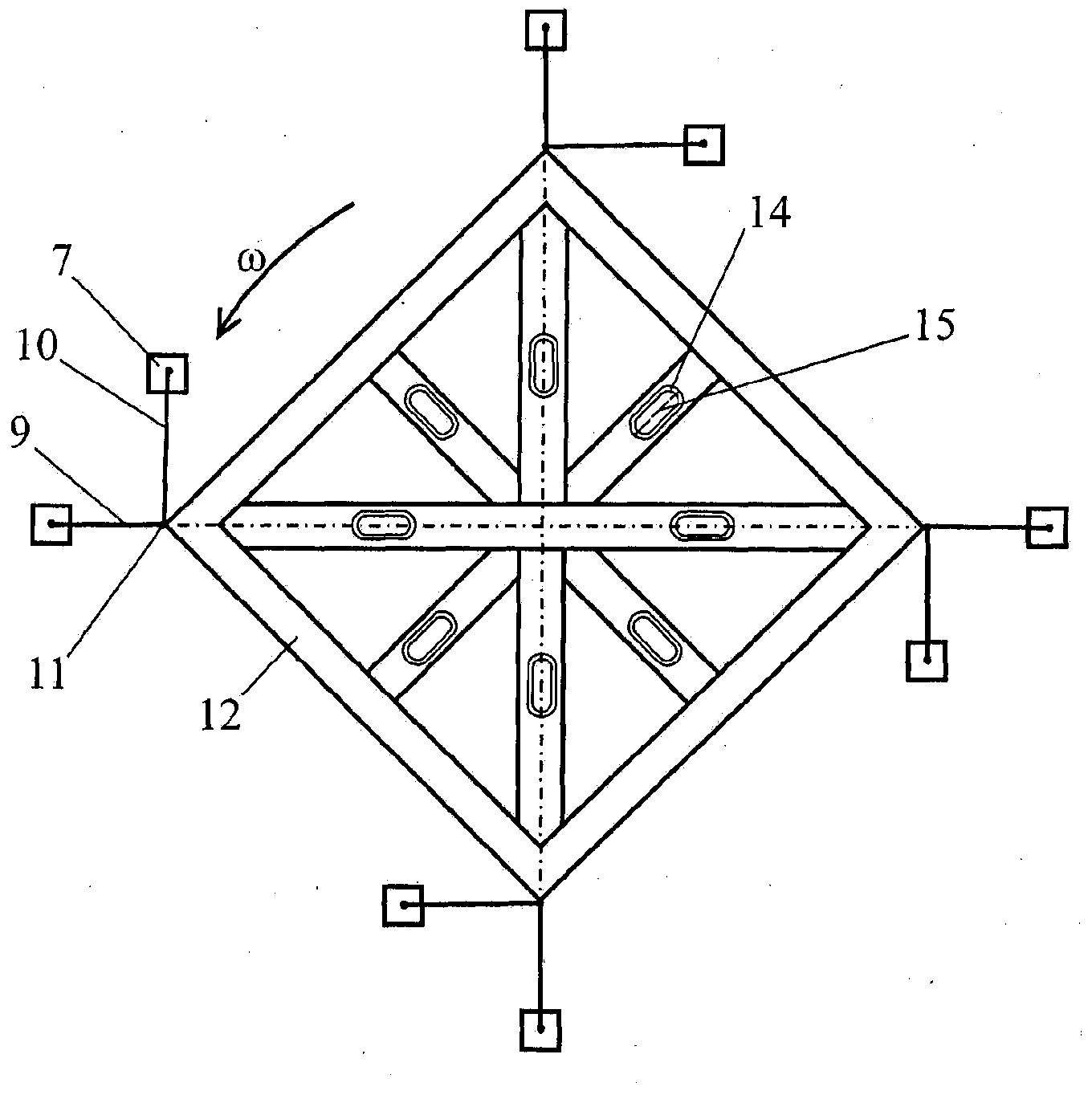

[0024] The wind power plant comprises a platform 1 surrounded by an annular pontoon 2, a kinematic mechanism 3 capable of transferring the rotational energy of the annular pontoon 2 to a receiving unit 4 of an energy converter (the energy converter is not fully shown in the figure).

[0025] The blades 5 are arranged on an annular pontoon 2 rotatable relative to a vertical axis 6 . The platform 1 is formed to be floatable and is provided with positioning means comprising at least 6 anchors 7 located on the bottom 8 of the body of water, preferably in pairs, and by means of flexible members (cables or chains) 9 and 10 are connected to the platform 1 such that the horizontal plane projection of one flexible member 9 is oriented radially to the axis of rotation 6 of the annular pontoon 2 and the projection of the second flexible member 10 is oriented tangentially, the anchor 7 connected to it relative to the flexible The points 11 of attachment of the members 9 and 10 to the floa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com