De-icing mechanism for high-voltage wire de-icing device

A technology of high-voltage wires and deicing racks, which is applied in the installation of cables, electrical components, and overhead installations. It can solve problems affecting the construction of the national power grid, avoid strand breakage under high voltage, improve the effect of deicing, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

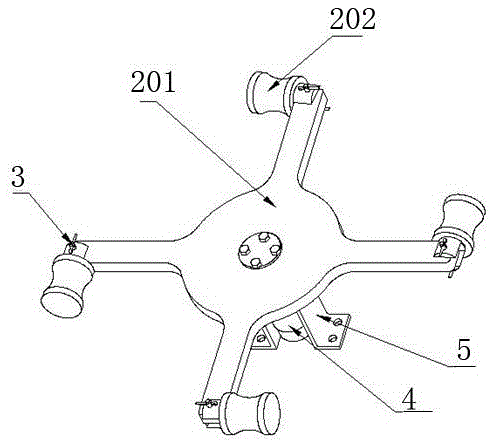

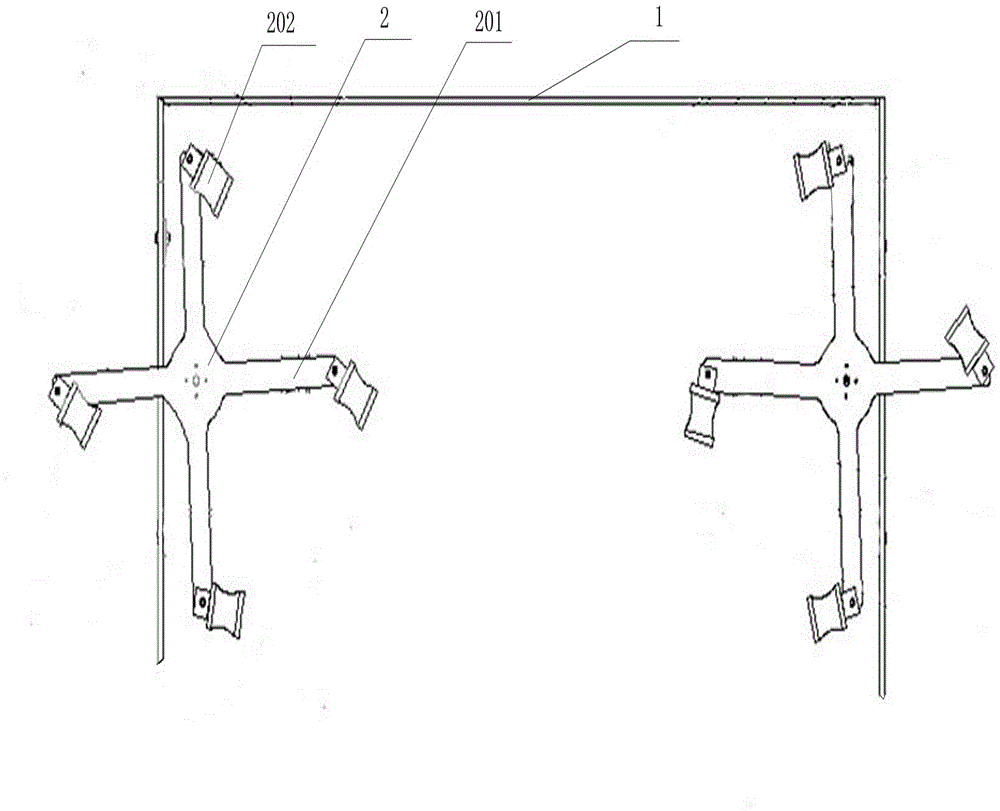

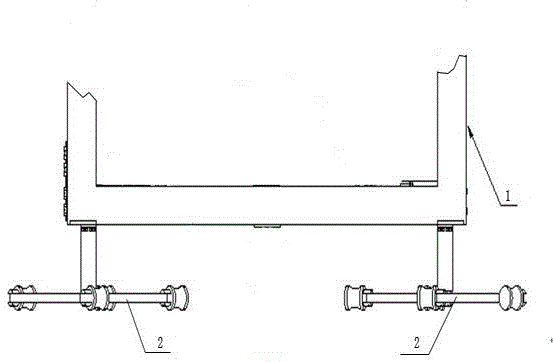

[0016] As shown in the figure, the deicing mechanism for the high voltage wire deicing device includes a frame 1 and a deicing assembly 2 arranged on the frame 1 . The deicing assembly 2 is provided with a deicing rack 201 driven by the power mechanism, and the periphery of the deicing rack 201 is provided with a deicing rubber rod 202 capable of hitting high-voltage wires during the rotation of the deicing rack 201 .

[0017] The deicing assembly 2 is arranged between the upper and lower high-voltage wires through the frame 1, so as to strike the upper and lower high-voltage wires simultaneously during the rotation.

[0018] There are two deicing assemblies described in this specific embodiment, and the rotation directions of the two deicing assemblies are opposite. tap.

[0019] The deicing assembly can also be two groups, each gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com