Inorganic nano phase-change energy storage material prepared by double-decomposition reaction and preparation method thereof

A phase change energy storage material and metathesis reaction technology, applied in the field of low-carbon energy saving in buildings, can solve the problems of supercooling and phase separation of phase change energy storage materials, and achieve the effects of low cost, easy quality control and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Weigh industrial grade aluminum sulfate Al 2 (SO 4 ) 3 376.2g, add 1000g of water to dissolve, drop 0.1M dilute sulfuric acid to make the Al(OH)3 floc just dissolve, filter to remove impurities;

[0024] (2) Weigh 328g of trisodium phosphate and add it to the aqueous solution of step (1). The ratio of trisodium phosphate to aluminum sulfate is 2:1.1, and stir while adding to obtain nano-sized aluminum phosphate AlPO 4 Precipitate 244g, filter, and the filtrate is concentrated to sodium sulfate saturation;

[0025] (3) Add the filtrate of step (2) into twice the volume of ethanol to obtain nano-scale sodium sulfate Na 2 SO 4 .10H 2 O 966g and nanoscale aluminum sulfate Al 2 (SO 4 ) 3 .18H 2 O 66.6g, filtered;

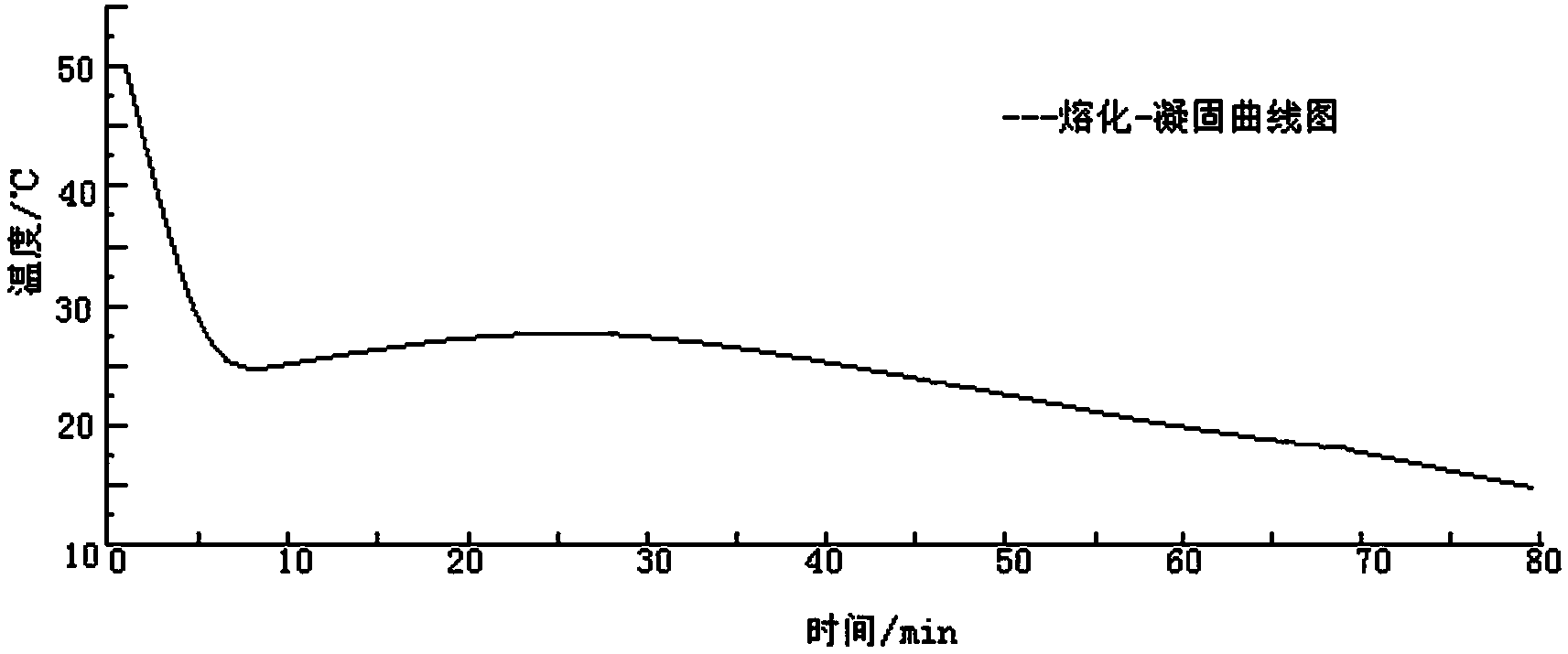

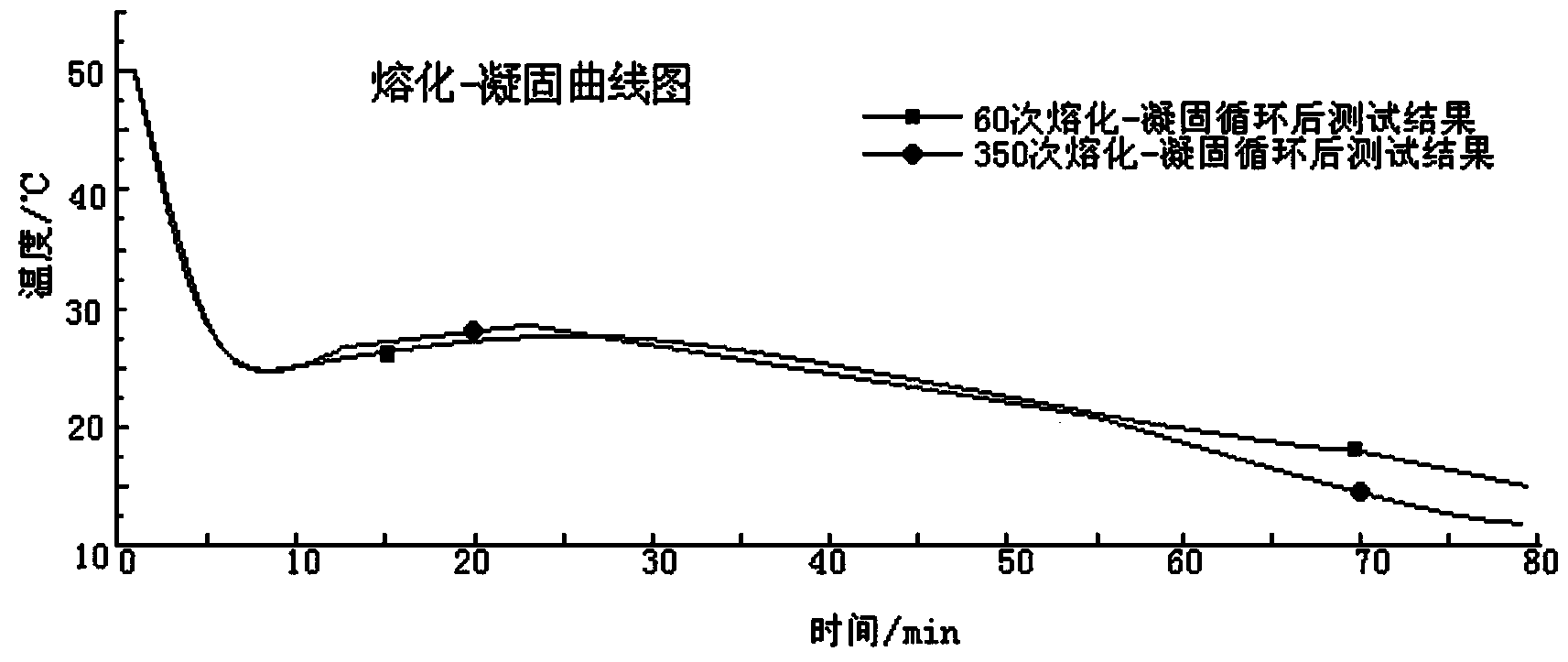

[0026] (4) Incorporate step (2) nano-AlPO 4 244g and step (3) nanoscale sodium sulfate Na 2 SO 4 .10H 2O 966g and nanoscale aluminum sulfate Al 2 (SO 4 ) 3 .18H 2 O 66.6g was mixed, added 1.3 kg of water and stirred, heated at 40°C for 60 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat storage density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com