Coke oven burner hot-repairing material and preparation method thereof

A technology of hot repair material and furnace head, which is applied in the field of coking refractory materials. It can solve problems such as insufficient strength, cold repair is not allowed, and damage to matrix silica bricks, so as to achieve stable coke pushing current, avoid secondary coke, The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

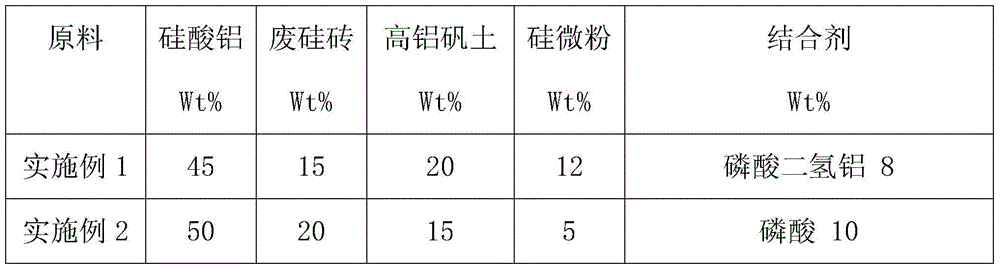

[0013] Raw material preparation: among the prepared raw materials: aluminum silicate aggregate particle size 0-2mm, and Al 2 o 3 ≥60wt%; waste silica brick particle size 0~1mm, and SiO 2 ≥92wt%; high bauxite particle size 2 o 3 ≥75wt%; silica powder particle size 2 ≥92wt%.

[0014] Mix aluminum silicate aggregate particles, waste silica brick particles, high-alumina bauxite micropowder, silica micropowder and binder according to the ratio in Table 1. Mix the materials in a mixer for 20 minutes, and put them into a sealed bucket after mixing. Place the material for 2 days to wake up, and make the hot repair material for the burner of the coke oven.

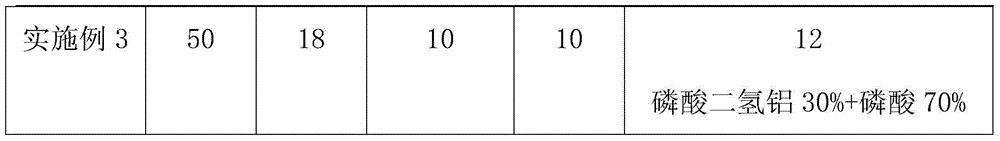

[0015] Table 1 embodiment raw material composition ratio table

[0016]

[0017]

[0018] Table 2 shows the comparative results of Examples and Comparative Examples.

[0019] Table 2 embodiment and comparative example result comparison table

[0020]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com