Textile machine, standby position determining method of driven member of winding unit, and winding unit

A technology for driving parts and standby positions, applied in the field of textile machinery, which can solve problems such as heavy burden on manufacturing operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

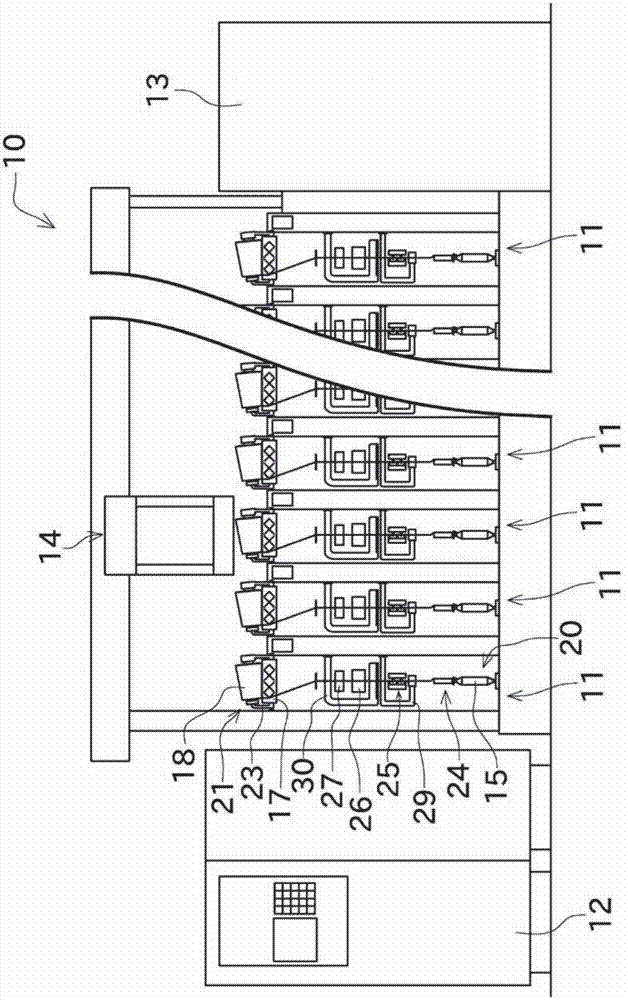

[0038] Next, an automatic winder according to an embodiment of the present invention will be described with reference to the drawings. figure 1 It is a front view showing a schematic configuration of the automatic winder 10 of the present embodiment.

[0039] Such as figure 1 As shown, an automatic winder (textile machine) 10 includes a plurality of winding units 11 arranged in parallel, a machine control device 12, a yarn supply bobbin supply device 13, and a doffing device 14 as main components.

[0040] The machine control device 12 is configured to be able to communicate with each winding unit 11 . The operator of the automatic winder 10 can collectively manage the plurality of winding units 11 by appropriately operating the machine control device 12 .

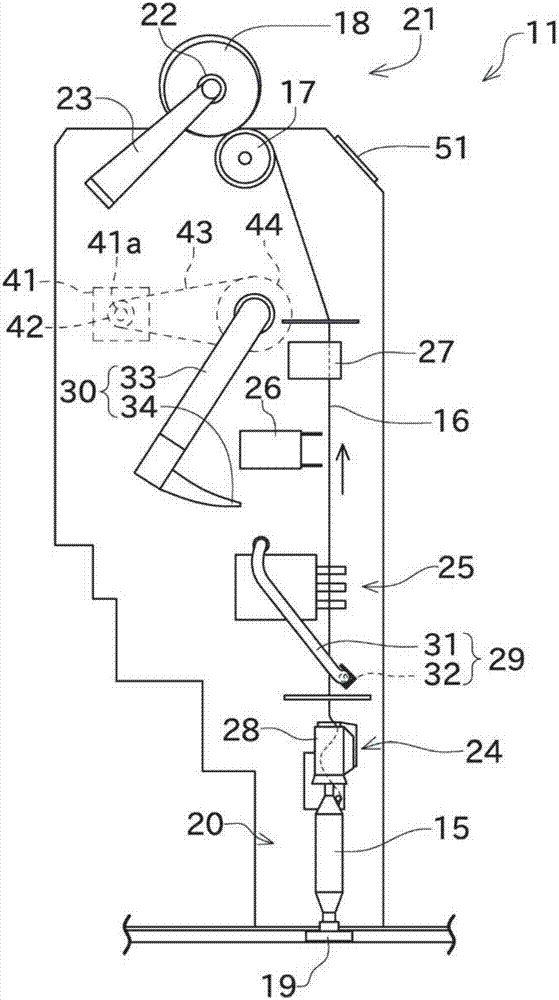

[0041] Each winding unit 11 is configured to unwind the yarn from the yarn supply bobbin 15, and wind the unwound yarn 16 to the take-up bobbin while moving the unwound yarn 16 laterally. The winding bobbin in the state...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com