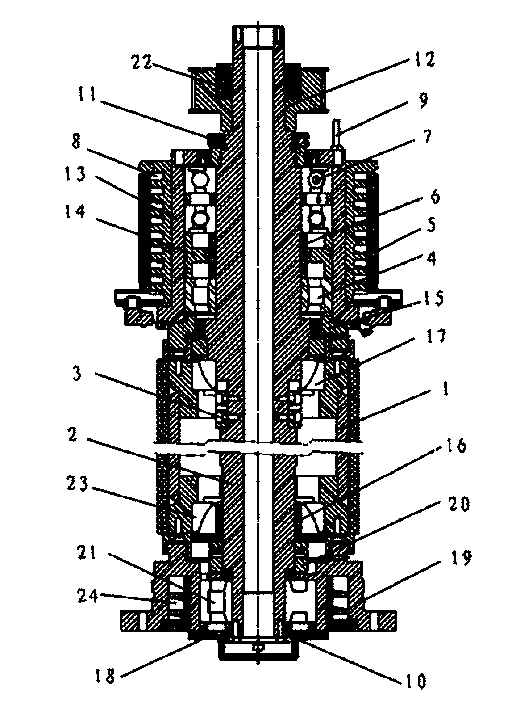

Main shaft system of multi-wire cutting machine

A multi-wire cutting machine and spindle technology, which is applied to fine working devices, working accessories, stone processing equipment, etc., can solve the problems of poor cooling environment, poor sealing effect, short system working life, etc. The effect of simple parts, easy assembly and replacement of line rollers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

[0024] see figure 1 As shown, a multi-wire cutting machine spindle system includes a wire roller 1, a mandrel 2, and the wire roller 1, mandrel 2 and nut 20 are axially fastened and connected, and the upper end of the mandrel 2 is fastened to the pulley 12 through an expansion sleeve 22 For torque input, it also includes: a first spherical bearing 17 and a second spherical bearing 23 that are supported and positioned at both ends of the wire roll 1, the first spherical bearing 17 is directly connected to the mandrel 2, and the second spherical bearing 23 is connected to the mandrel A sliding sleeve 16 is provided between the two, a key 3 is provided between one end of the wire roller 1 and the mandrel 2, a bearing seat 13 is provided outside the upper end of the mandrel 2, and a pair of angular contact balls are provided between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com