A kind of wood flame retardant and preservative and the process for preparing flame retardant and preservative wood by using the same

A preservative, wood technology, applied in anti-corrosion, smoke-suppressing wood flame retardant and the process of treating solid wood with its flame retardant and anti-corrosion, in the field of flame retardant, can solve the problem of excessive investment in wood flame retardant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

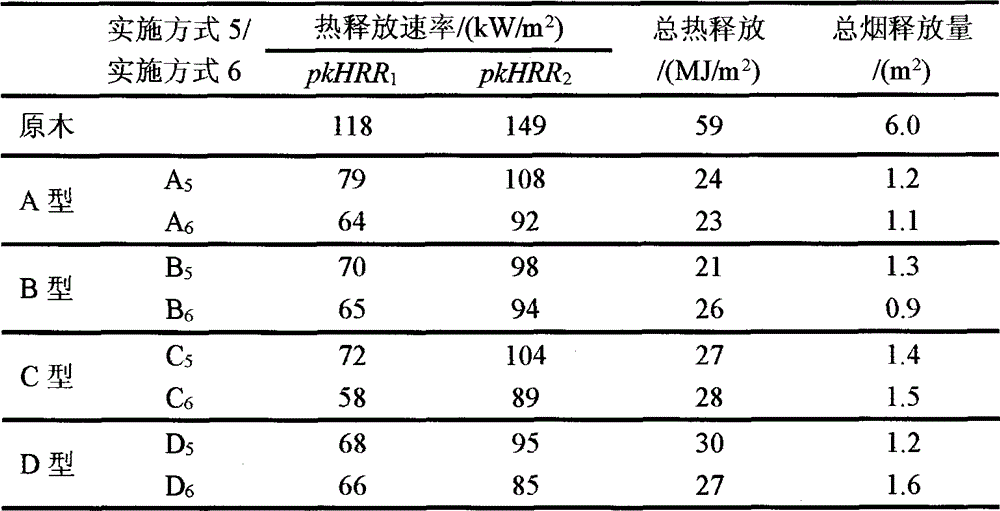

[0017] Specific embodiment one: The new type A wood flame retardant preservative of this embodiment is formulated according to the following weight percentages: BPW55-60%, diammonium phosphate 20-30%, boric acid 10-20%, ammonium molybdate 1-3 %.

specific Embodiment approach 2

[0018] Specific embodiment two: the new type B wood flame retardant preservative of this embodiment is formulated according to the following weight percentages: BPW50~60%, diammonium phosphate 20~30%, boric acid 15~20%, ammonium molybdate 1~2 %.

specific Embodiment approach 3

[0019] Specific embodiment three: The new type C wood flame retardant preservative of this embodiment is formulated according to the following weight percentages: BPW60-70%, diammonium phosphate 15-20%, boric acid 10-15%, ammonium molybdate 1-3 %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com