Rail switch lifting device

A technology of lifting device and switch, which is applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of running piles, complex structure, and easy damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

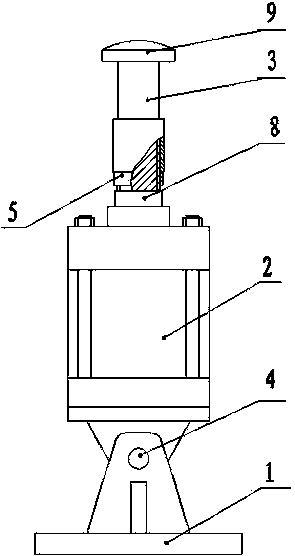

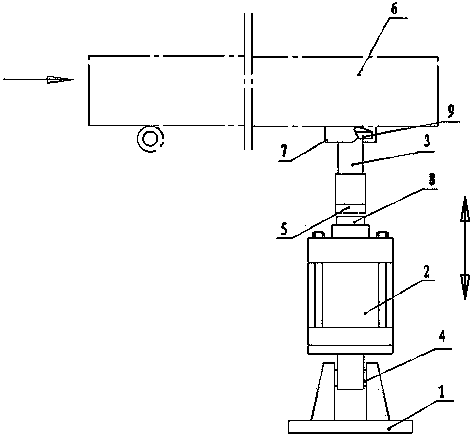

[0019] Such as figure 1 The point switch lifting device shown includes a support base 1, a cylinder 2 and a connecting block 3. The clip 9 at the upper end of the connecting block 3 is in clearance fit with the slot 7 under the steel rail 6, and the clip 9 is in the Can swing laterally in the draw-in groove 7, the chuck 9 on the upper end of the connecting block is preferably a spherical crown, which can reduce the friction between the connecting block 3 and the steel track 6; The connection is preferably a threaded connection, and a lock nut 5 is arranged between the connecting block 3 and the guide post 8 of the cylinder 2 to play a reinforcing role; 3. The top is spherical, and the cylinder 2 can preferably be a heavy-duty cylinder of the type QGBZ125*60-MP3 produced by Jinan Jiefeite Cylinder Co., Ltd.; the connection between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com