TSV process method without metal CMP

A process method and metal technology, applied in the field of metal-free CMP TSV process, can solve the problems of high barrier layer cost, expensive CMP equipment, no mention of metal-free CMPTSV process, etc., to reduce costs, lower industrialization threshold and The effect of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0044] A TSV process method free of metal CMP, comprising the following steps:

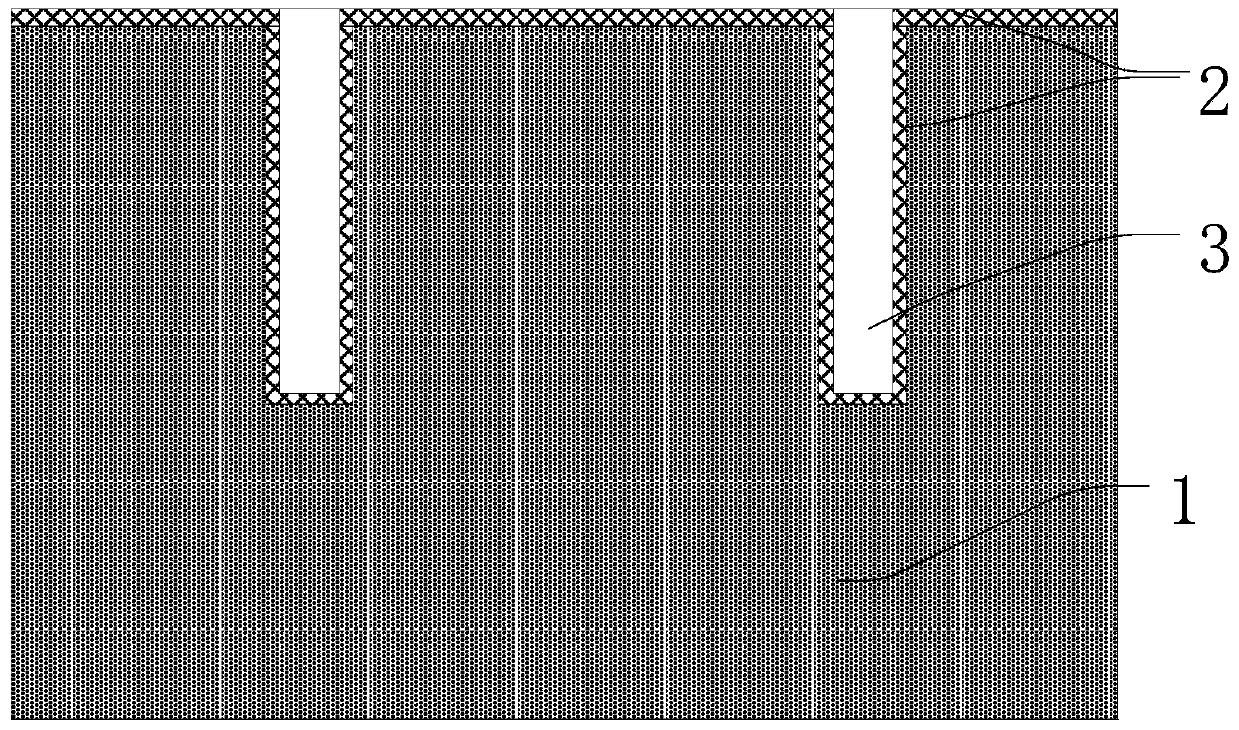

[0045] S1. If figure 1 As shown, a wafer 1 is provided as a substrate, a blind hole 3 (TSV hole) is formed in the wafer 1 by a deep reactive ion etching process, and an insulating layer 2 is formed on the upper surface of the wafer 1 and the inner wall of the blind hole 3 ;

[0046] The depth and diameter of the blind hole 3 can be determined according to specific requirements, and the aspect ratio is generally not less than 3:1. The material of the insulating layer 2 may be materials such as silicon dioxide, silicon nitride, silicon oxynitride, organic polymer, etc., and the layer structure may be a one-layer or multi-layer structure of the above materials.

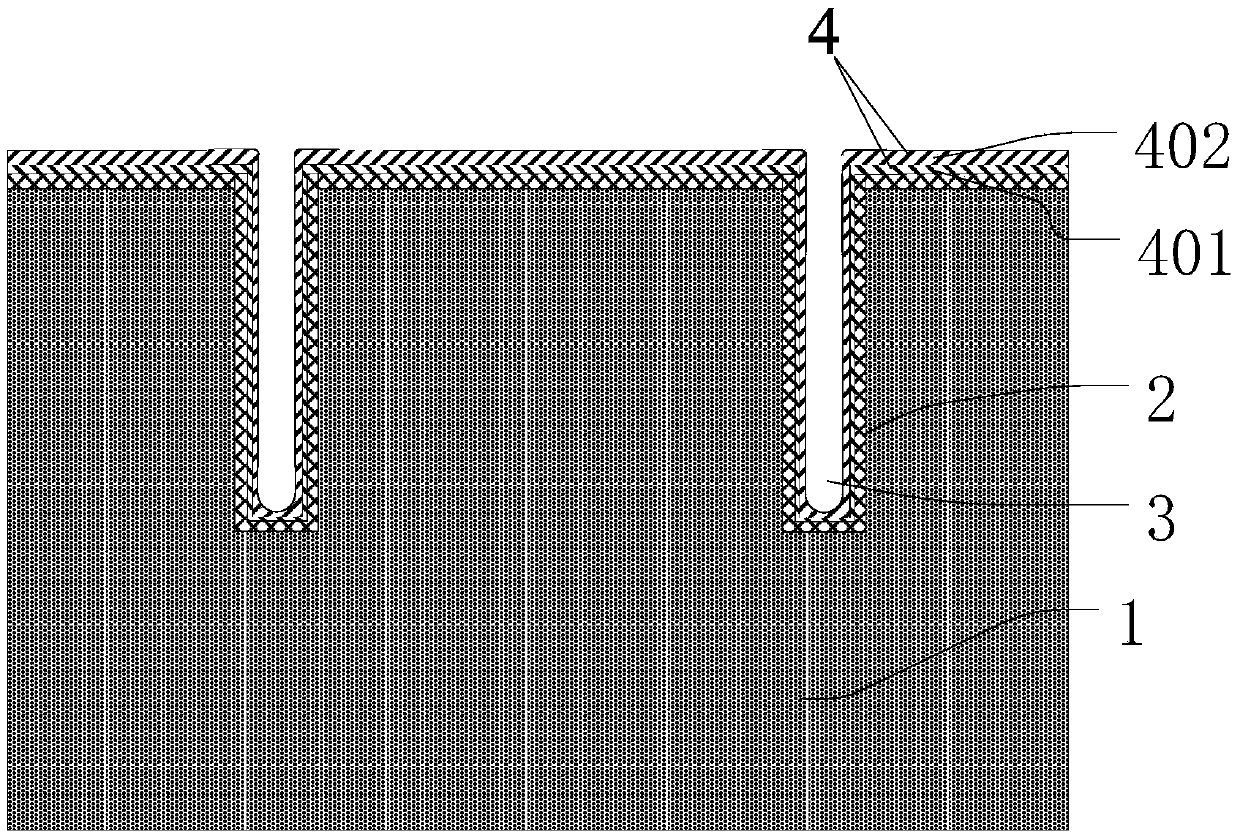

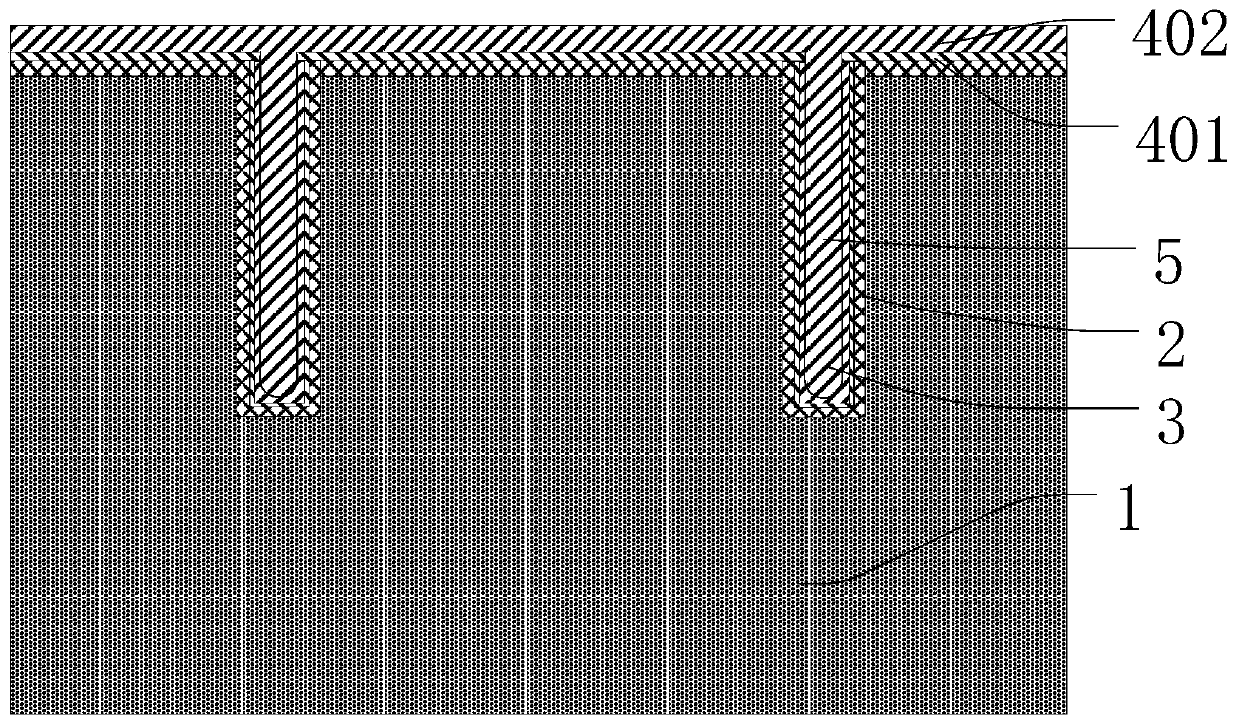

[0047] S2. If figure 2 As shown, a barrier layer 401 and a seed layer 402 are deposited on the upper surface of the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com