Intelligent Least Squares Pesticide Waste Liquid Incinerator Furnace Temperature Optimization System and Method

A least squares, incinerator technology, applied in general control systems, control/regulation systems, temperature control and other directions, can solve the problems of too low or too high furnace temperature, difficult to control furnace temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

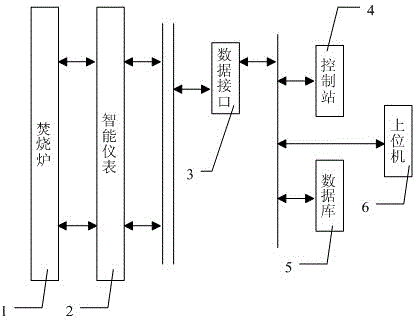

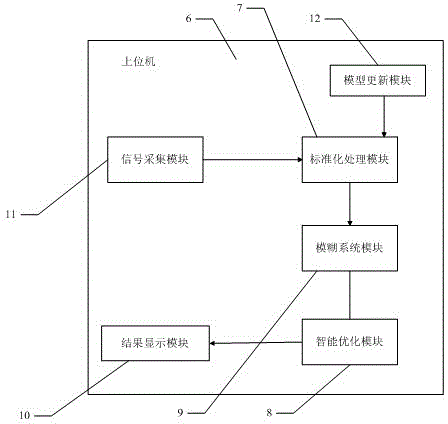

[0105] refer to figure 1 , figure 2 , an intelligent least squares system for optimizing the furnace temperature of a pesticide waste liquid incinerator, including an on-site intelligent instrument 2 connected to an incinerator object 1, a DCS system and a host computer 6, and the DCS system includes a data interface 3 and a control station 4 And database 5, described field smart instrument 2 is connected with data interface 3, and described data interface is connected with control station 4, database 5 and host computer 6, and described host computer 6 comprises:

[0106] The standardization processing module 7 is used to preprocess the model training samples input from the DCS database, centralize the training samples, that is, subtract the average value of the samples, and then standardize it:

[0107] Calculate the mean: TX ‾ = 1 N Σ i = ...

Embodiment 2

[0153] refer to figure 1 , figure 2 , an intelligent least squares method for optimizing the furnace temperature of the pesticide waste liquid incinerator, the specific implementation steps of the method are as follows:

[0154] 1) Determine the key variables used, collect the data of the variables when the production is normal from the DCS database as the input matrix of the training sample TX, and collect the corresponding furnace temperature to optimize the operating variable data as the output matrix O;

[0155] 2) Preprocess the model training samples input from the DCS database, and centralize the training samples, that is, subtract the average value of the samples, and then standardize them so that the mean value is 0 and the variance is 1. This processing is accomplished using the following algorithmic procedure:

[0156] 2.1) Calculate the mean: TX ‾ = 1 N Σ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com