Method for analyzing influence of mentholated cigarette processing process on production environment

A technology for production environment and processing process, applied in the field of environmental detection and analysis, can solve problems such as lack of accurate determination of menthol cigarette menthol concentration, and achieve the effects of reducing production line and production environment pollution, simple operation and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

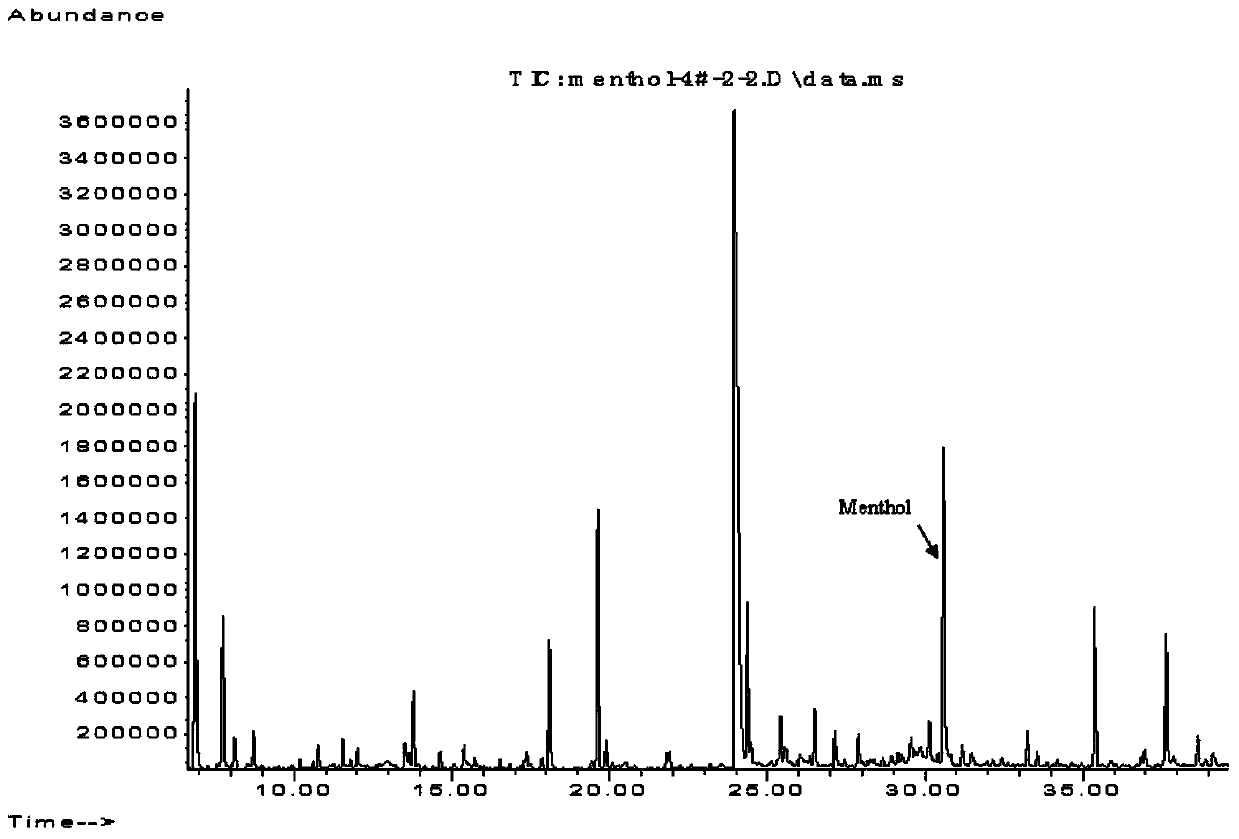

Image

Examples

Embodiment 1

[0041] 1 material

[0042] 1.1 Instrument

[0043] 6890GC / 5973MS gas chromatography / mass spectrometry (Agilent, USA); TurboMatrix ATD thermal desorption instrument (Perkin Elmer, USA); Carbotrap349 adsorption sampling tube, gas collection pump (Supelco, USA); flow meter (AALBORG, USA) .

[0044] 1.2 Reagents and samples

[0045] Cigarette samples (selected from Shanghai Cigarette Factory); menthol standard samples (purity 99.0%, Bailingwei Technology Co., Ltd.); absolute ethanol (purity 99.9%, American ACS Enke Chemicals).

[0046] 2 methods

[0047] In order to analyze the impact on the surrounding environment during the production of menthol cigarettes, the following experiments were carried out to investigate the diffusion and concentration changes of menthol in the production environment: In the same production site, 1# machine produced menthol cigarettes, 2#, 3#, Machine 4# produces other types of cigarettes at the same time (distance from machine 1#: 2#<3#<4#).

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com