A yarn bobbin suitable for yarn fluffing, pilling and grinding, and its preparation and application

A technology for pilling and yarn bobbins, which is applied in the preparation of test samples, the use of mechanical devices, measuring devices, etc., can solve the problems of the stability of the wound yarn layer and the structural characteristics of the simulated fabric without a solution. The film is evenly and stably pasted, with good bonding effect and not easy to peel off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention also provides a method for preparing the above-mentioned yarn bobbin suitable for fluffing, pilling and grinding, the steps of which are as follows:

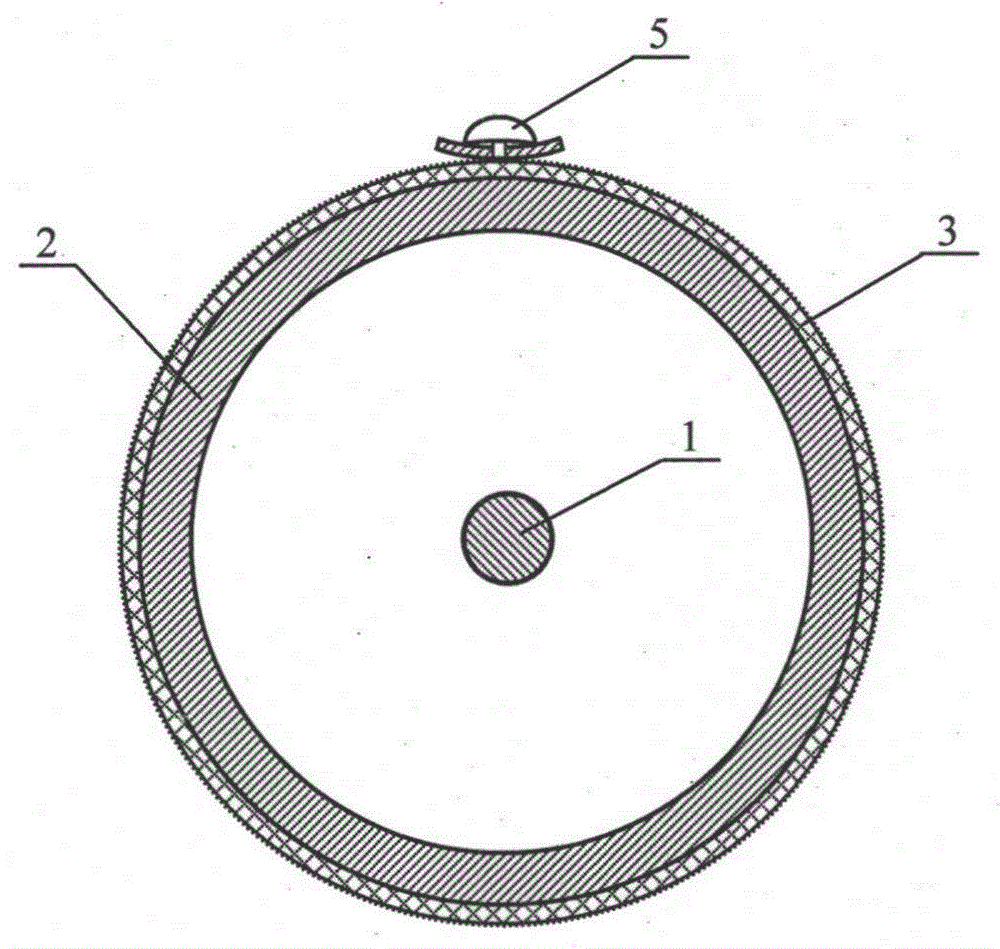

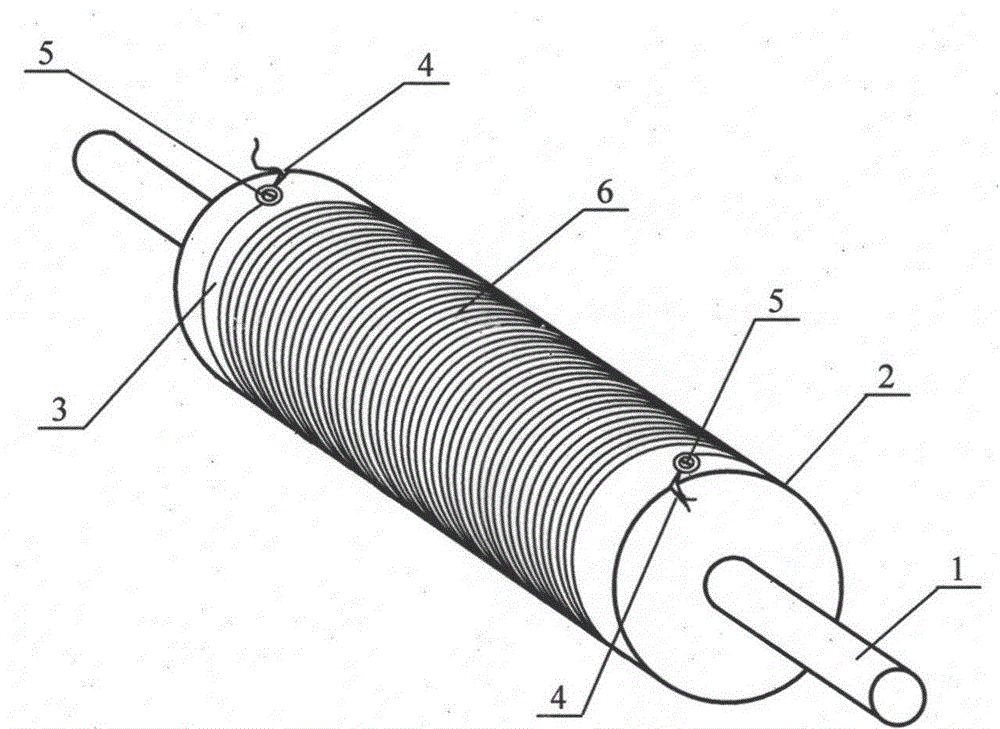

[0029] The first step, pasting the polymer film 3: first paste the smooth surface of the polymer film 3 with a smooth surface on one side and a rough surface on the other side with a thickness of 0.5-3 mm to the metal cylinder 2 through an adhesive, Its rough surface is used to contact with the winding yarn 6, so that the ground winding yarn 6 is stably depressed in it by the rough surface of the polymer film 3 and held by the rough surface, keeping the winding yarn 6 wound in the outer layer. Stablize;

[0030] The second step, slotting the yarn tube: on the edge corners of the left and right ends of the metal tube 2, respectively open a slot 4, and the left and right slots 4 are located on the cylindrical surface of the metal tube 2. , and the edge of the slot 4 along the opposite direction of the...

Embodiment 1

[0033] The preparation method of the present invention is adopted to obtain a bobbin with a polyurethane film with a thickness of 1mm on the surface, and the double-strand yarn of the full wool 2×8.2tex with a yarn number of 16.4tex is wound on the surface of the bobbin with a tension of 10cN , the winding yarn 6 is naturally stably depressed in the polyurethane film with a rough outer surface and held by its rough surface. There is no dislocation and overlapping of the winding yarn 6 in the whole close-packed winding. The whole friction along the axis of winding yarn 6, winding yarn 6 has no movement; friction along the axis of metal cylinder 2, winding yarn 6 has no obvious movement and tumbling; the friction of the compounded Lissajous curve trajectory of the two, winding yarn 6 has no Noticeable movement and tumbling. The head end of the winding yarn 6 is wound 3 times on the left yarn head nail and the tail end is wound 1 circle on the right yarn head nail, which can eff...

Embodiment 2

[0035]The preparation method of the present invention is adopted to obtain a bobbin with a rubber film with a thickness of 2 mm on the surface, and the cashmere / polyester composite yarn of 7.7 tex is wound on the surface of the bobbin with a tension of 3 cN, and the wound yarn 6 is naturally stably Depressed in and gripped by the roughened rubber membrane on the outer surface. There is no dislocation and overlapping of the winding yarn 6 in the whole close-packed winding. The whole friction along the axis of winding yarn 6, winding yarn 6 has no movement; friction along the axis of metal cylinder 2, winding yarn 6 has no obvious movement and tumbling; the friction of the compounded Lissajous curve trajectory of the two, winding yarn 6 has no Noticeable movement and tumbling. The head end of the winding yarn 6 is wound 2 times on the left yarn head nail and the tail end is wound 2 times on the right yarn head nail, which can effectively fix the winding yarn 6. The acute angle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com