Piezoelectric extrusion type magnetorheological clutch and transfer torque calculating method of piezoelectric extrusion type magnetorheological clutch

A squeeze and clutch technology, applied in the direction of fluid clutch, clutch, calculation, etc., can solve the occasions that cannot be used to transmit large torque and limited use space, clutch transmission performance and service life decline, magnetorheological The clutch is easy to leak and other problems, to achieve the effect of good sealing, enhanced torque transmission capacity, and elimination of slip process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

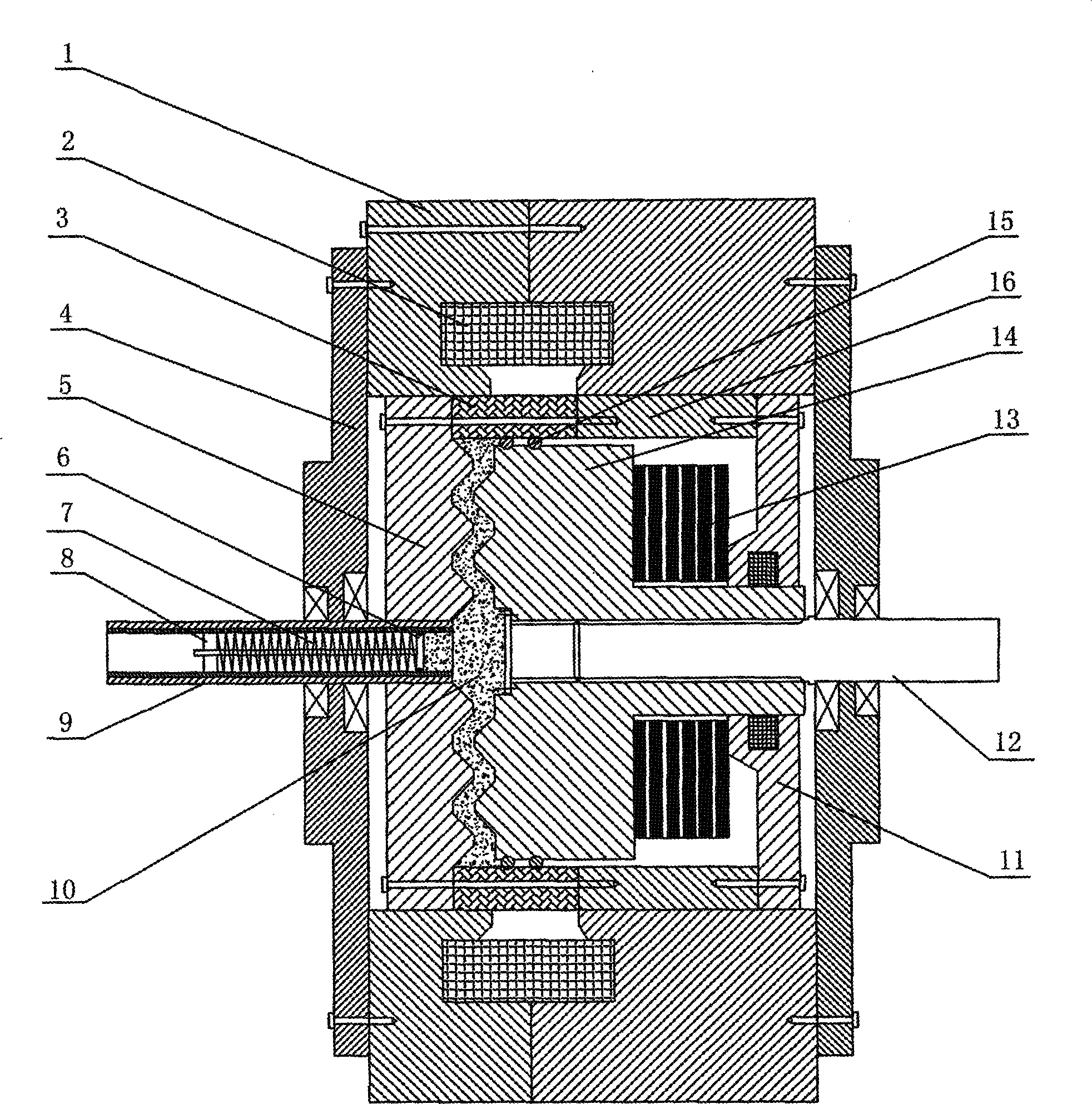

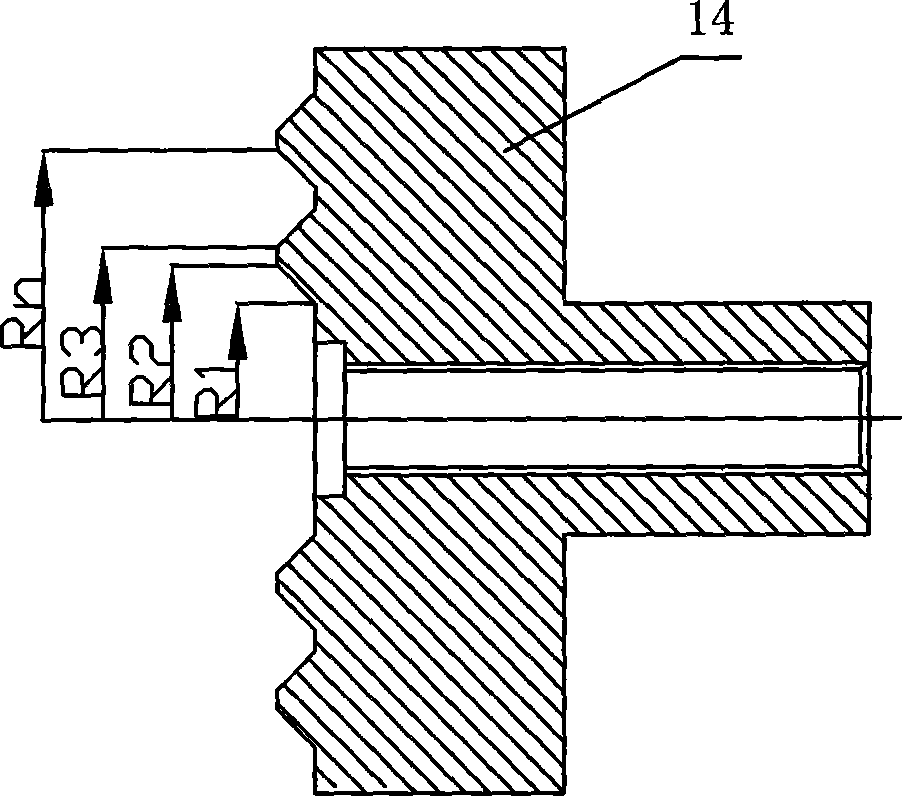

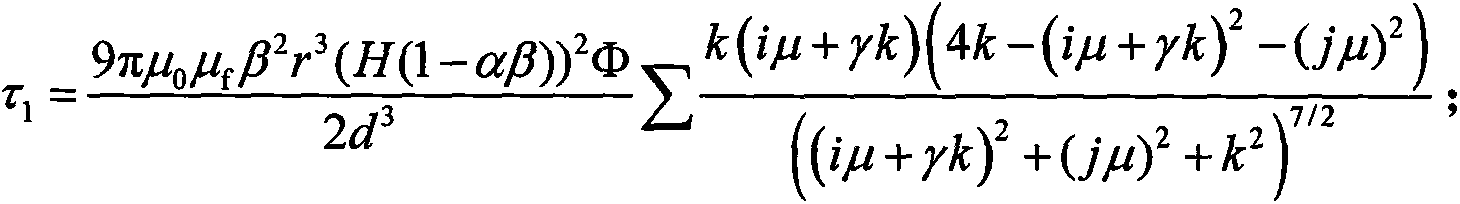

[0020] refer to figure 1 , figure 2 It is an embodiment of the piezoelectric extrusion magneto-rheological clutch and its transmission torque calculation method of the present invention. The piezoelectric extrusion magneto-rheological clutch includes a housing 1 provided with a cylindrical through hole, and the housing 1 The two ends are respectively provided with outer end caps 4 that close the through holes, and the coil 2 is arranged in the housing 1, and the driving disk 5 and the driven disk 14 are arranged in the said through holes, and the driving disk 5 and the driven disk 14 is provided with a magnetorheological fluid 10, and the working surface of the driving disk 5 is provided with at least two circles of concentric convex strips, the convex strips are concentric with the driving disk 5, and the working surface of the driven disk 14 is provided with At least two circles of grooves adapted to the protruding strips. The driving disk 5 is connected with the driving s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com