Production method of biodiesel

A biodiesel and production method technology, applied in biofuel, fatty acid production, petroleum industry, etc., can solve problems such as poor separation effect of acid residue, low energy utilization rate, and reduced acid value, so as to improve the efficiency of esterification reaction, The effect of saving methanol consumption and reducing alcohol consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Pretreatment of raw oil

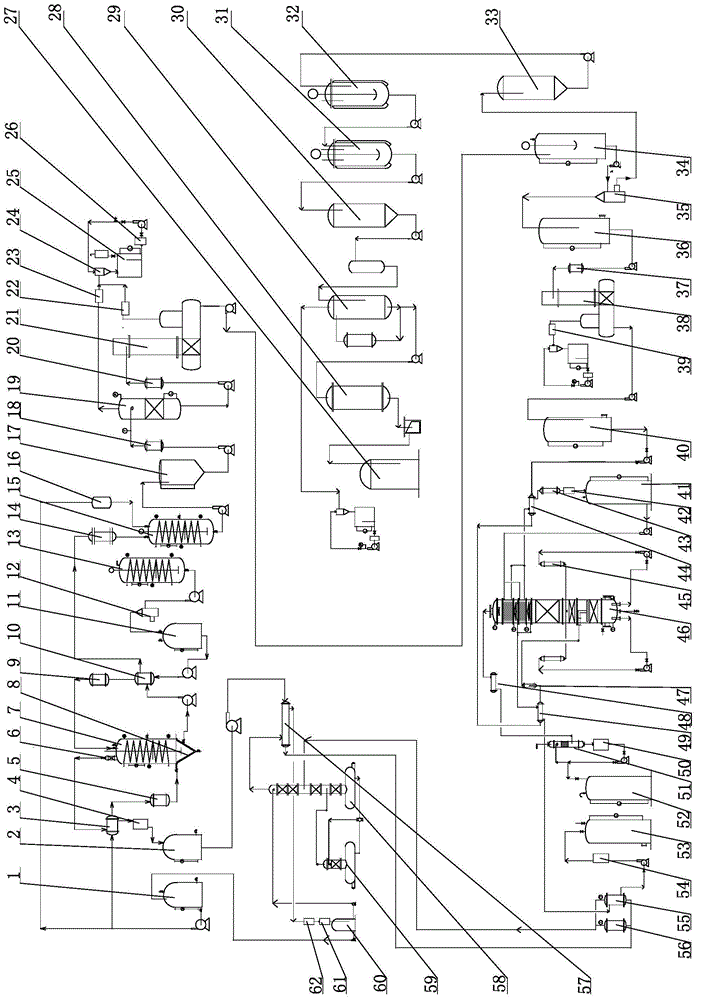

[0034] Such as figure 1 As shown, the acid value of 14 tons is 120mgKOH / g, the impurity content is 1%, the water content is 5%, the saponification value is 190mgKOH / g, and the density is 0.91kg / m 3 Put the waste oil into the raw oil pretreatment kettle 13, add 1.4 tons of water, turn on the stirring device of the raw oil pretreatment kettle 13, and feed steam to the raw oil pretreatment kettle 13 at the same time, heat the waste oil to 60°C, and continue steaming Keep constant temperature, after stirring for 40 minutes, add 42kg methanesulfonic acid, continue to stir at constant temperature for 60 minutes, then add 4.2kg of polyacrylamide with a molecular weight of 12 million, stir at constant temperature for 60 minutes, open the valve at the bottom of raw material oil pretreatment kettle 13, The waste oil is pumped into No. 1 butterfly centrifuge 12 with an oil pump for centrifugal separation, and the waste oil that removes mechanical impu...

Embodiment 2

[0052] In the pretreatment step 1 of the feedstock oil in Example 1, 14 tons of oil had an acid value of 120 mgKOH / g, an impurity content of 1%, a moisture content of 5%, a saponification value of 190 mgKOH / g, and a density of 0.91 kg / m 3Put the waste oil into the raw oil pretreatment kettle 13, add 2.1 tons of water, turn on the stirring device of the raw oil pretreatment kettle 13, and supply steam to the raw oil pretreatment kettle 13 at the same time, heat the waste oil to 80 ° C, and continue to pass steam Keep constant temperature, after stirring for 20 minutes, add 14kg methanesulfonic acid, continue to stir at constant temperature for 30 minutes, then add 7kg of polyacrylamide with a molecular weight of 10 million, and stir at constant temperature for 30 minutes, open the valve at the bottom of raw material oil pretreatment kettle 13, and use The waste oil is pumped into No. 1 butterfly centrifuge 12 by the oil pump for centrifugation, and the waste oil that removes col...

Embodiment 3

[0054] In the pretreatment step 1 of the feedstock oil in Example 1, 14 tons of oil had an acid value of 120 mgKOH / g, an impurity content of 1%, a moisture content of 5%, a saponification value of 190 mgKOH / g, and a density of 0.91 kg / m 3 Put the waste oil into the raw oil pretreatment kettle 13, add 2.1 tons of water, turn on the stirring device of the raw oil pretreatment kettle 13, and supply steam to the raw oil pretreatment kettle 13 at the same time, heat the waste oil to 80 ° C, and continue to pass steam Keep constant temperature, after stirring for 20 minutes, add 70kg methanesulfonic acid, continue to stir at constant temperature for 30 minutes, then add 1.4kg of polyacrylamide with a molecular weight of 18 million, stir at constant temperature for another 30 minutes, open the valve at the bottom of raw material oil pretreatment kettle 13, The waste oil is pumped into No. 1 butterfly centrifuge 12 with an oil pump for centrifugal separation, and the waste oil that rem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com