Reflector attaching equipment

A reflective sheet and sticking technology, applied in the direction of layered products, lamination devices, lamination, etc., can solve the problems of product yield dependence, increase labor costs, poor continuous working ability, etc., to improve accuracy and stability, The effect of improving attachment efficiency and improving output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with various embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

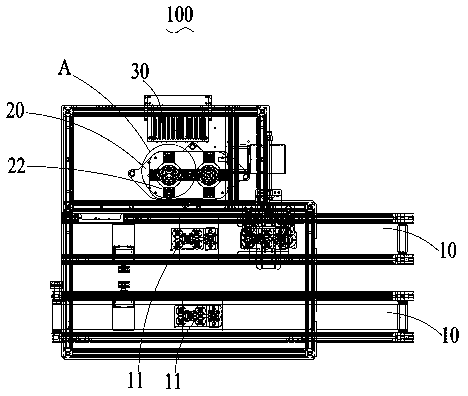

[0024] ginseng figure 1 As shown, the reflective sheet attachment equipment 100 provided by the present invention includes:

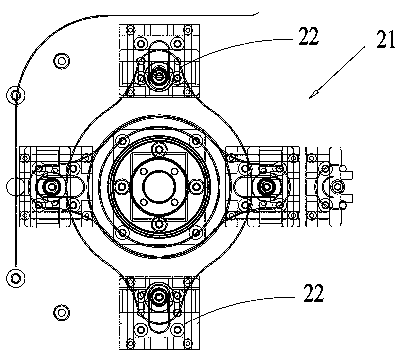

[0025] Attachment assembly 20, the attachment assembly 20 includes a correction member 21 and a manipulator connected to the correction member 21, the correction member 21 includes a number of correction blocks 22, and an additional working area is defined between the several correction blocks 22, so The attaching additional working area accommodates optical film materials, and the manipulator is used to attach reflective sheets to the optical film materials;

[0026] The assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com