Automatic locking screw device

An automatic locking screw and screw technology, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of high difficulty of locking, inability to clamp and arrange, and affect the correctness of assembly tightness and assembly, so as to reduce the Labor cost, the effect of mass production labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Relevant detailed description and technical contents of the present invention are as follows with regard to coordinating illustrations now:

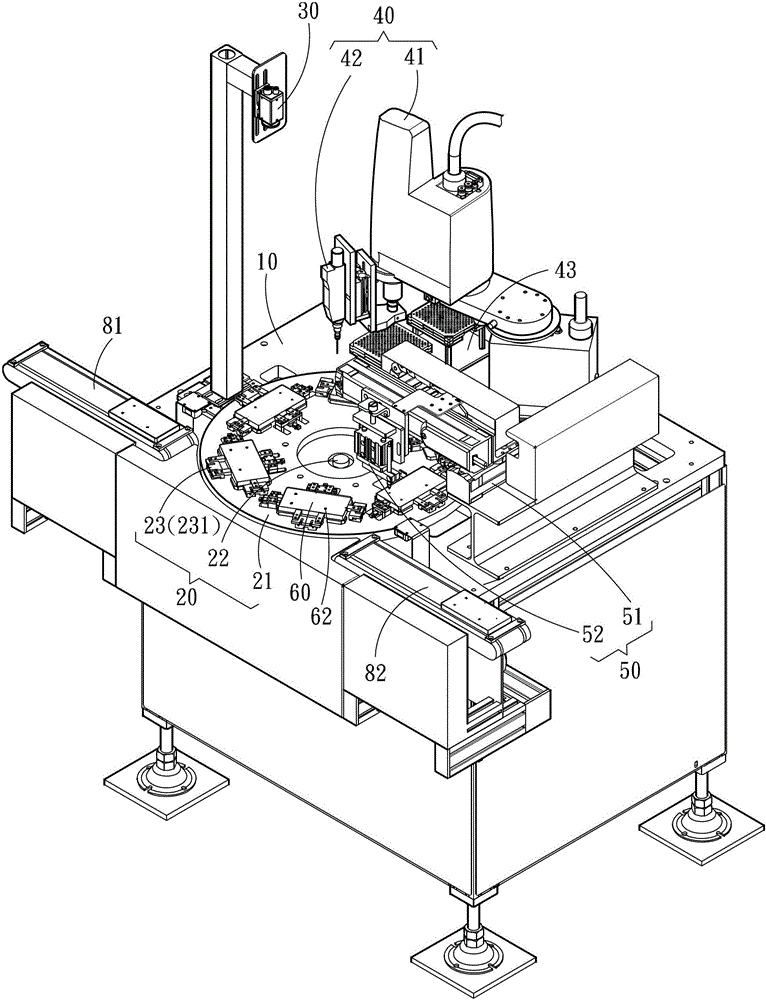

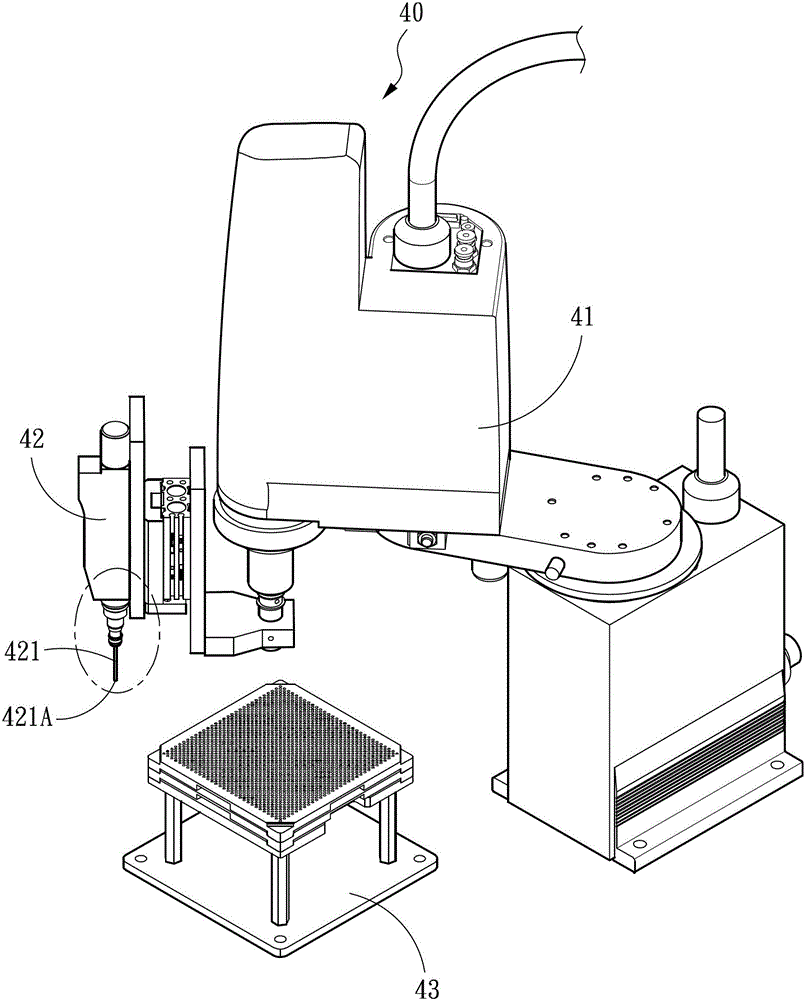

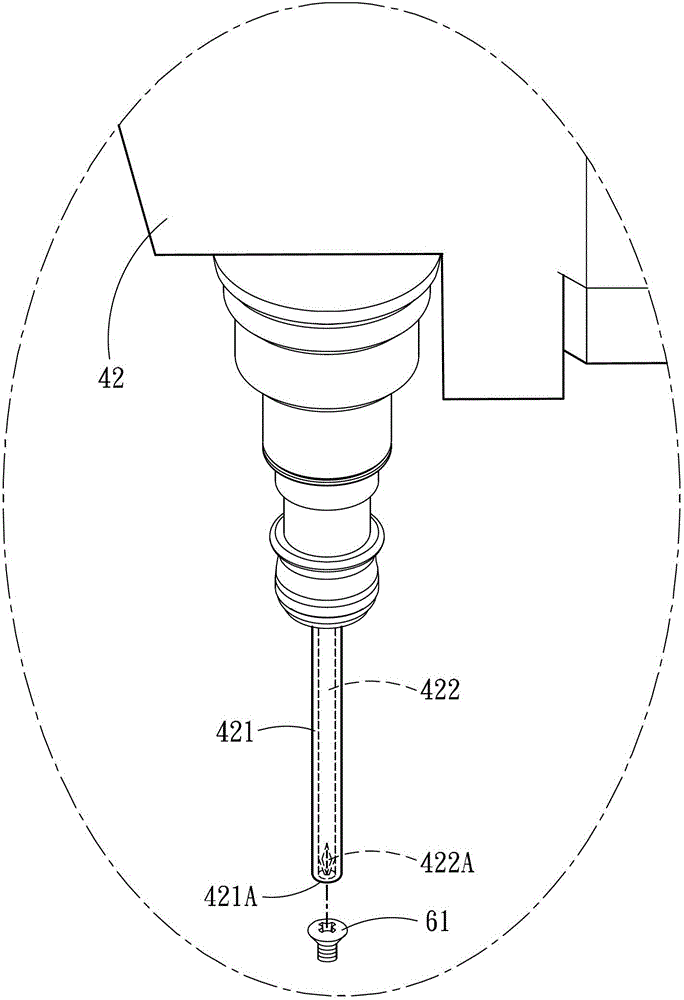

[0024] see figure 1 and Figure 4A to Figure 4C As shown, the present invention is an automatic locking screw device, which is used to lock at least one screw 61 (shown in Figure 2B ) into a screw hole 62 on a working object 60, the automatic screw locking device includes a working platform 10, a carrying mobile platform 20, an image observation module 30 for observing the position of the screw hole on the working object 60, together with A screw placement part 43 obtains the at least one screw 61 and locks it into the screw locking module 40 of the working object 60 , and a locking detection module 50 checks whether the screw 61 is locked correctly.

[0025] The carrying mobile platform 20 has a carrying part 21 for carrying and fixing the working object 60, and a moving part 22 connected with the carrying part 21. In this emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com