Traditional Chinese medicine composition for treating diabetes

A technology of composition and diabetes, which is applied in the direction of drug combination, metabolic disease, medical formula, etc., and can solve problems such as unproposed prescriptions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

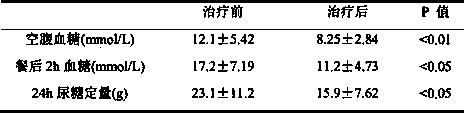

Image

Examples

Embodiment 1

[0016] The preparation of embodiment 1 granule of the present invention

[0017] Take 300g of silkworm chrysalis, 500g of cinnamon, 350g of bitter gourd, 450g of mulberry leaves, and 400g of spoon soup, cut into coarse grains, add 10 times the amount of water, heat at 90°C, keep stirring and extracting for 2 hours, coarsely filter and separate the medicinal residues, centrifuge the liquid at high speed, micro Porous filter membrane filtration, the filtrate depressurizes the concentrate to a clear paste with a relative density of about 1.20 (60°C), using starch and dextrin as auxiliary materials, and the weight ratio of the clear paste to auxiliary materials is 2:1, and passes through a fluidized fluidized bed , complete the spray drying at one time, and then pack it into a bag.

Embodiment 2

[0018] The preparation of embodiment 2 capsules of the present invention

[0019] Take 300g of silkworm chrysalis, 500g of cinnamon, 350g of bitter gourd, 450g of mulberry leaves, and 400g of spoon soup, cut into coarse grains and add 8 times the amount of water, heat at 80°C, stir and extract for 2 hours, separate the dregs by coarse filtration, centrifuge the liquid at a high speed, microporous Membrane filtration, the filtrate depressurizes the concentrated liquid to a clear paste with a relative density of about 1.05 (60°C), sprays and dries it once, and packs it into capsules.

Embodiment 3

[0020] The preparation of embodiment 3 tablet of the present invention

[0021] Take 300g of silkworm chrysalis, 500g of cinnamon, 350g of bitter gourd, 450g of mulberry leaves, and 400g of spoon soup, cut into coarse grains and add 12 times the amount of water, heat at 60°C, stir and extract for 2 hours, separate the dregs by coarse filtration, centrifuge the liquid at high speed, microporous Membrane filtration, the filtrate depressurizes the concentrated liquid to a clear paste with a relative density of about 1.30 (60°C), completes spray drying at one time, and compresses into tablets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com