Lower drying type automatic soya milk film forming machine

An automatic forming machine and tofu skin technology, applied in cheese substitutes, dairy products, applications, etc., can solve the problems of low production efficiency, poor product quality and hygiene standards, high labor intensity, etc., and achieve high production efficiency and convenient operation. , the effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

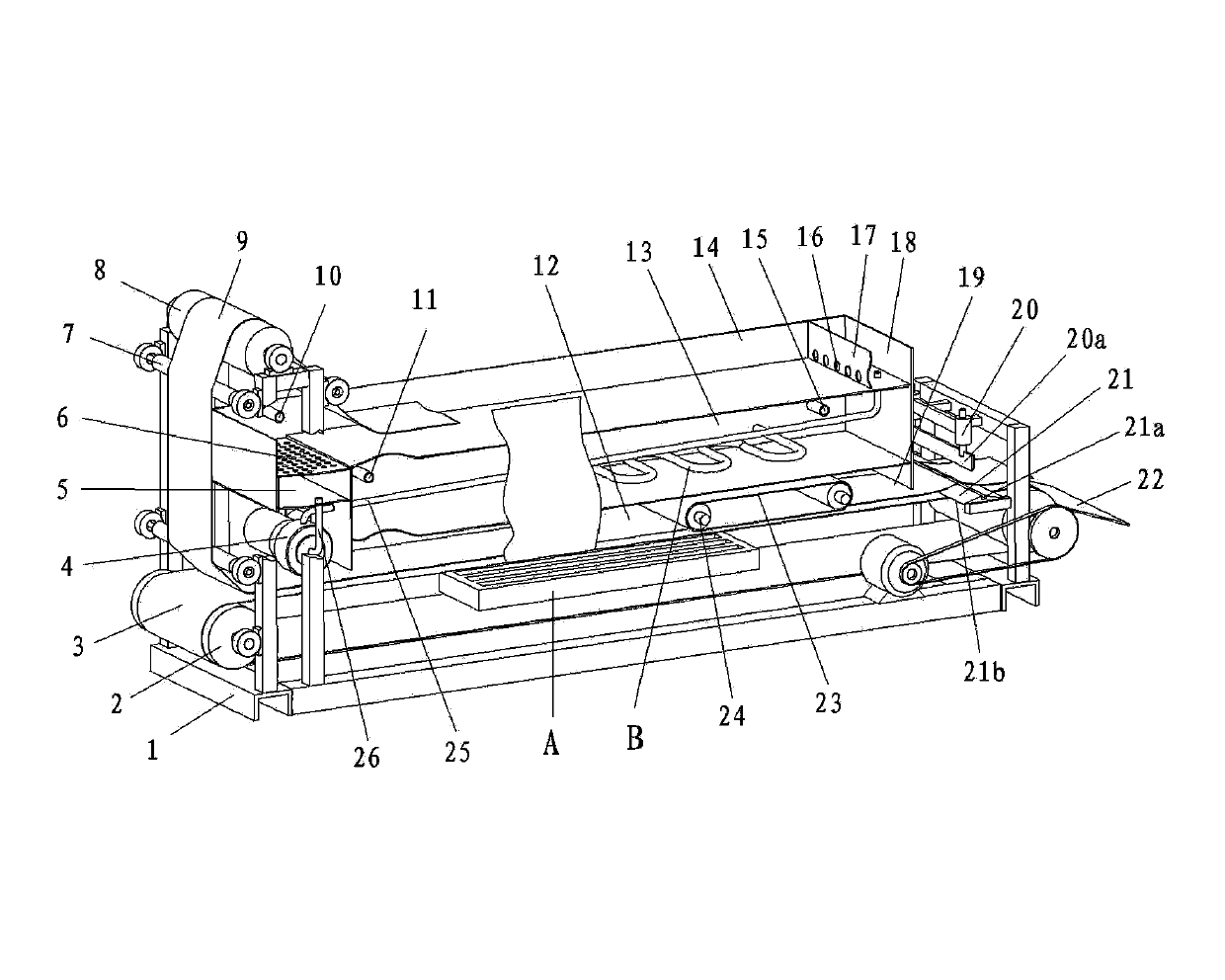

[0020] Embodiment 1: as figure 1 Shown, a kind of bottom drying type bean curd skin automatic molding machine provided by the present invention is characterized in that it comprises: frame 1, is provided with conveying device on frame 1, and it comprises: the conveying roller 2 that is arranged on frame two ends, The two ends of the conveying roller are connected with the supporting seat on the frame, and the conveying roller at one end is connected with a motor, and a conveying belt 3 is connected between the conveying rollers; the upper part of the conveying device on the frame 1 is sequentially provided with a drying tank 12 upwards , heating chamber 13, crusting tank 14, their main bodies are configured by H-shaped steel into three layers and welded with the baffle plates at both ends to be connected on the frame as a whole, the upper layer is used as a crusting tank for easy operation and cleaning, and the middle part is used as Heating chamber, the lower layer is the dry...

Embodiment 2

[0024] Embodiment 2: The difference from Embodiment 1 is that coil B is arranged in the heater, steam is passed into the coil, water is filled in the heater 13, the steam in the coil heats the water, and the circulating soybean milk passes through the heat of the heating chamber. Water is used for heating, and others are the same as in Example 1, and are not described again, and this structure is also applicable.

Embodiment 3

[0025] Embodiment 3: the difference with embodiment 1 is that heater A is set between the upper and lower sides of the conveyor belt, and the bean curd skin on the conveyor belt is dried by heater A. Others are the same as embodiment 1, and are not carried out Description, this structure can also be adopted.

[0026] Due to the adoption of the above technical solution, the present invention has simple structure, high production efficiency, low labor intensity, easy implementation, improved sanitary environment and product quality, suitable for large-scale production needs, and has the advantages of low processing cost and convenient operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com