Intensive supply system for cultivation feeding fodder and application method

A supply system and feed technology, applied in the field of livestock and poultry breeding, can solve the problems of difficult to grasp the accuracy of artificial feeding, unbalanced individual development, inconsistent feed intake, etc. The effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

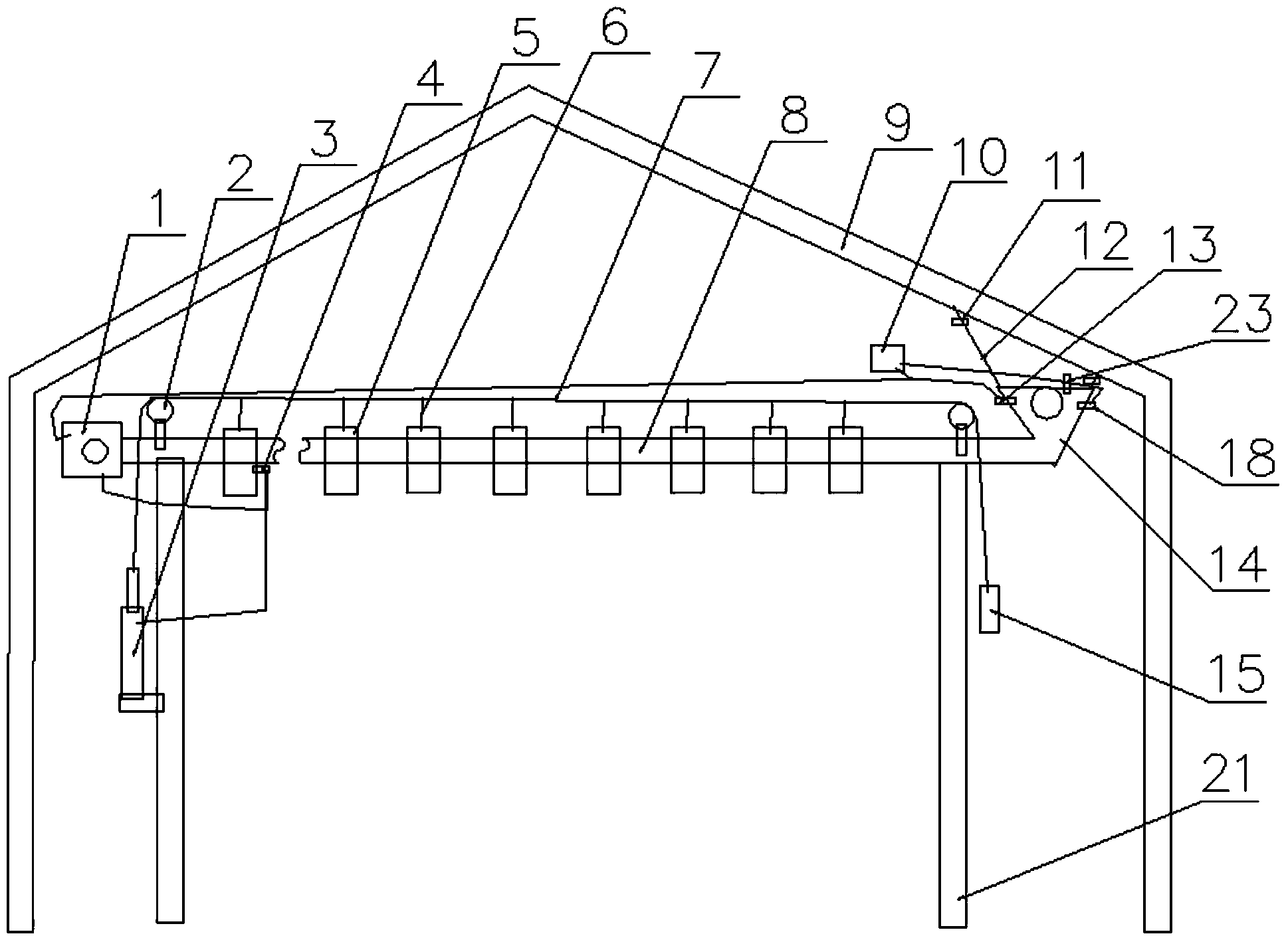

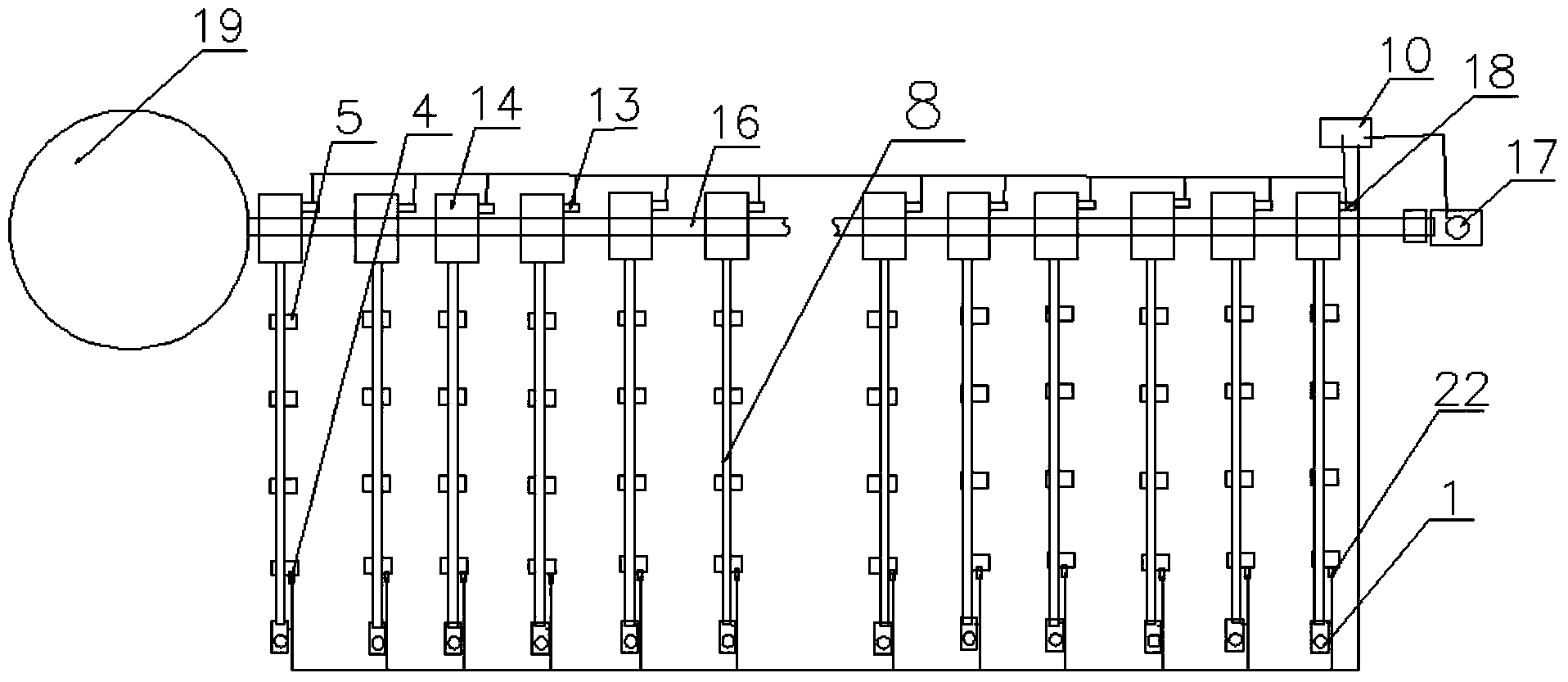

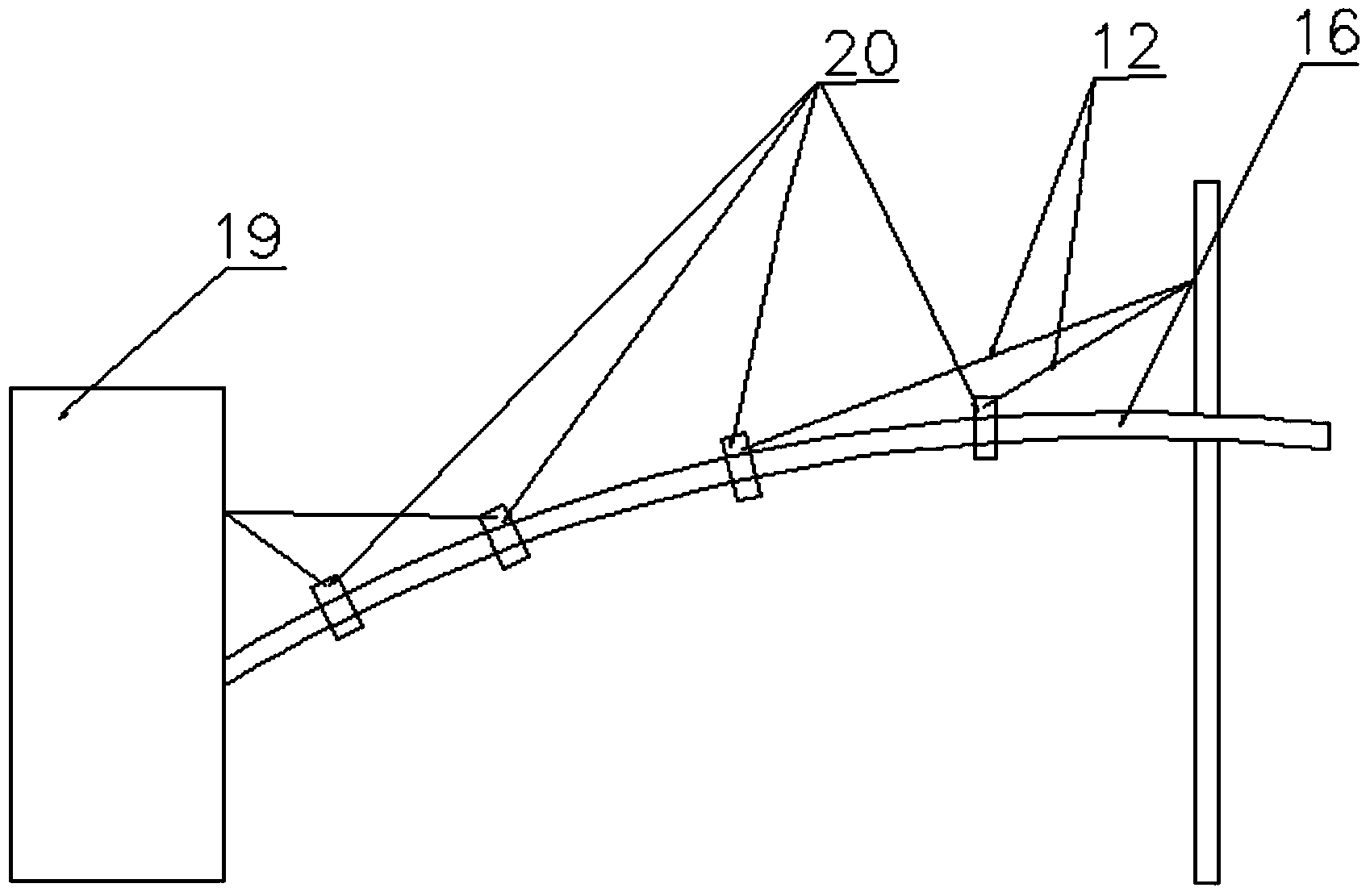

[0042] Such as Figure 1-7 As shown, a centralized supply system for aquaculture feeding feed includes a feeding device, a feeding device, a blanking device and an electric control device, and the feeding device includes at least one feed tank 19 and a screw feeding mechanism, and the screw feeding mechanism includes Feeding spring auger, the feeding motor 17 that is connected with feeding spring auger and the feeding pipe 16 that is sleeved on the feeding spring auger, described material dispensing device includes several turning hoppers 14 that are arranged on feeding pipe 16, and described rotating A material distribution pipe 8 with a material distribution spring auger is arranged on the hopper 14, and one end of the material distribution spring auger is connected to a material distribution motor 1; the blanking device includes several quantitative cups 5 arranged on the material distribution pipe 8 ; The electric control device includes a programmable controller 10 and se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com