Alternating-current deicing method based on flow cell

A technology of liquid flow battery and ice-melting method, which is applied in the installation of cables, electrical components, overhead installation, etc. It can solve the problems of ice-coated dancing wires, uneven tension of wires, and reduced insulation strength of insulators, so as to ensure safety and stability. , Improve ice-melting power and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

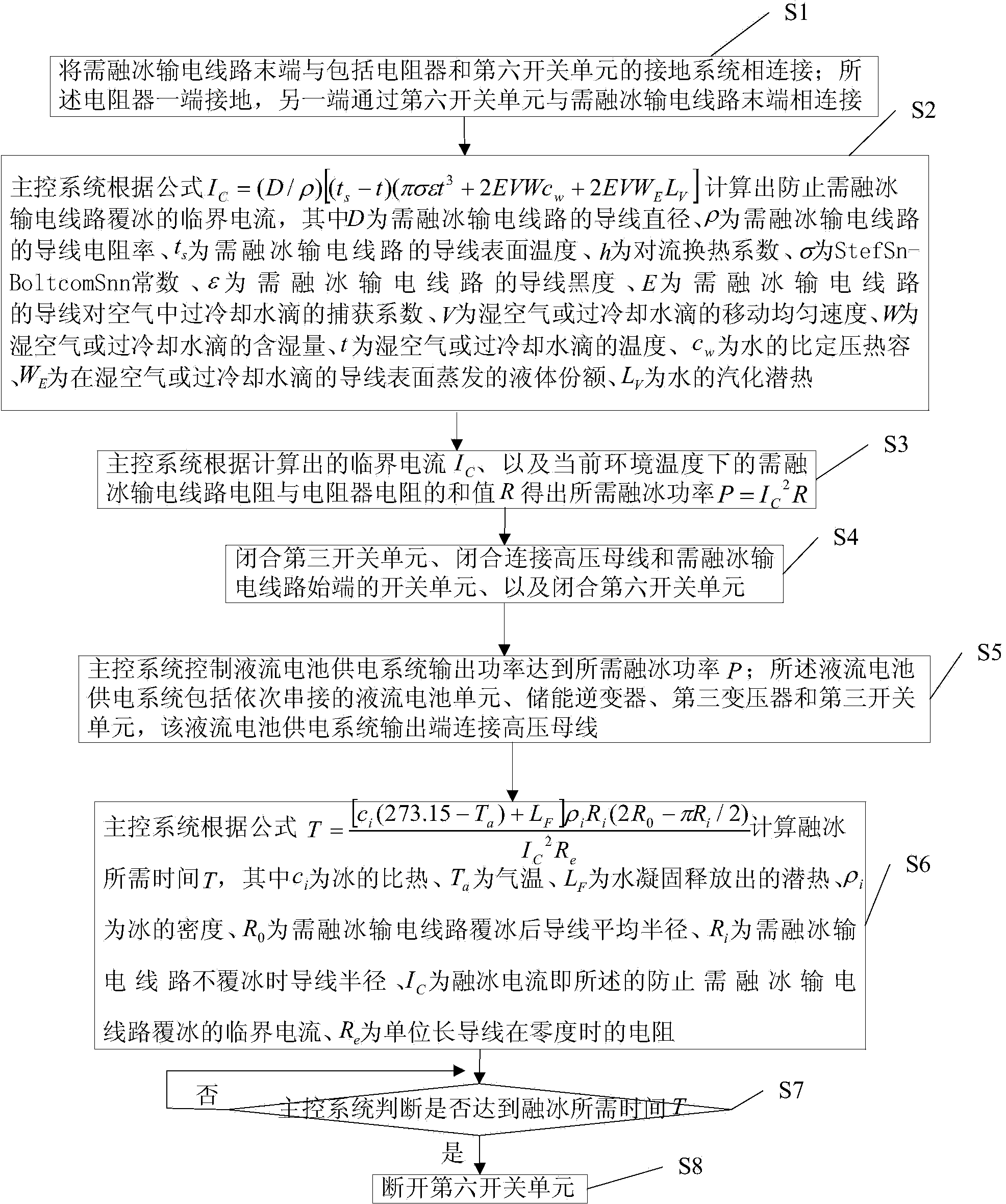

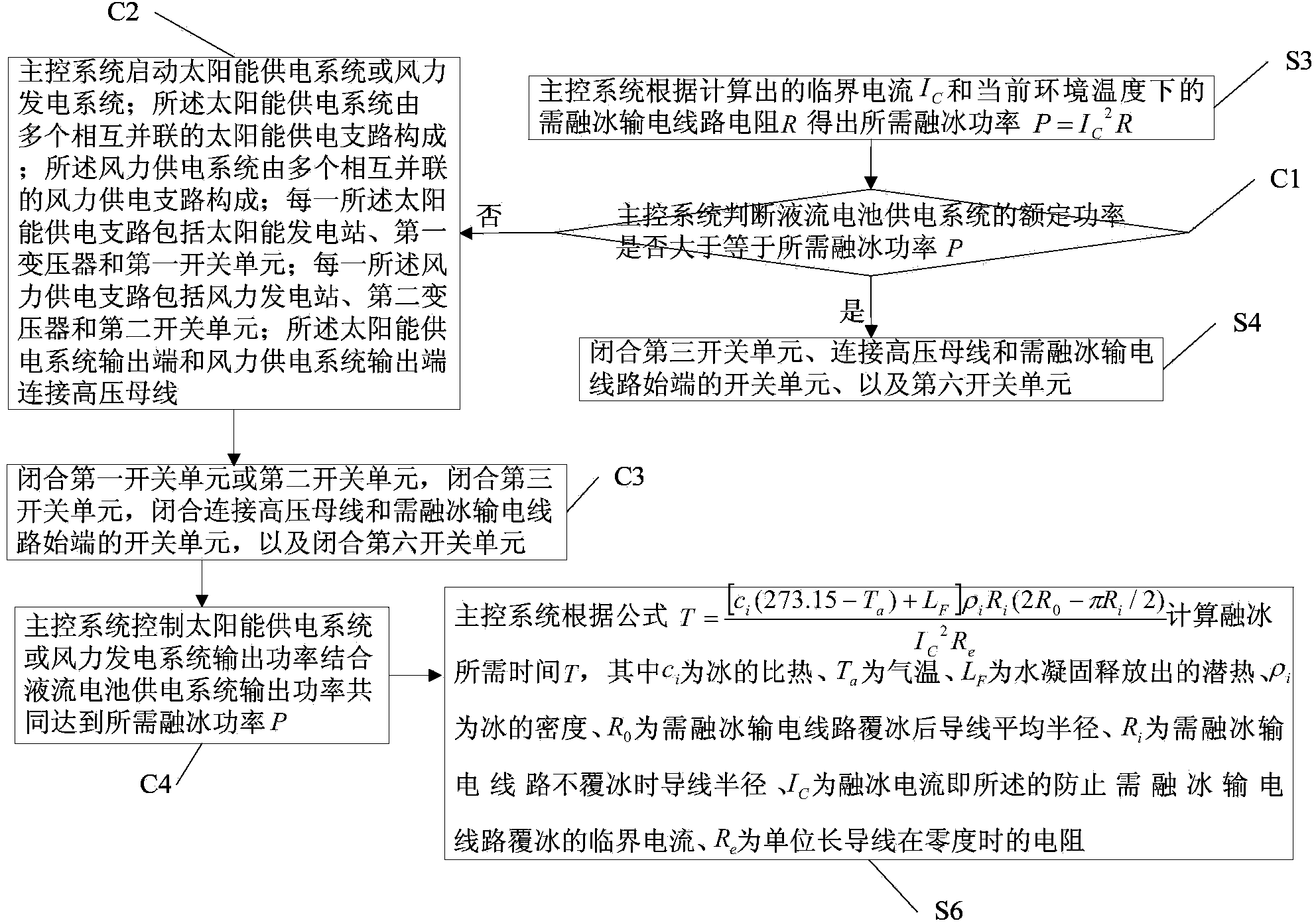

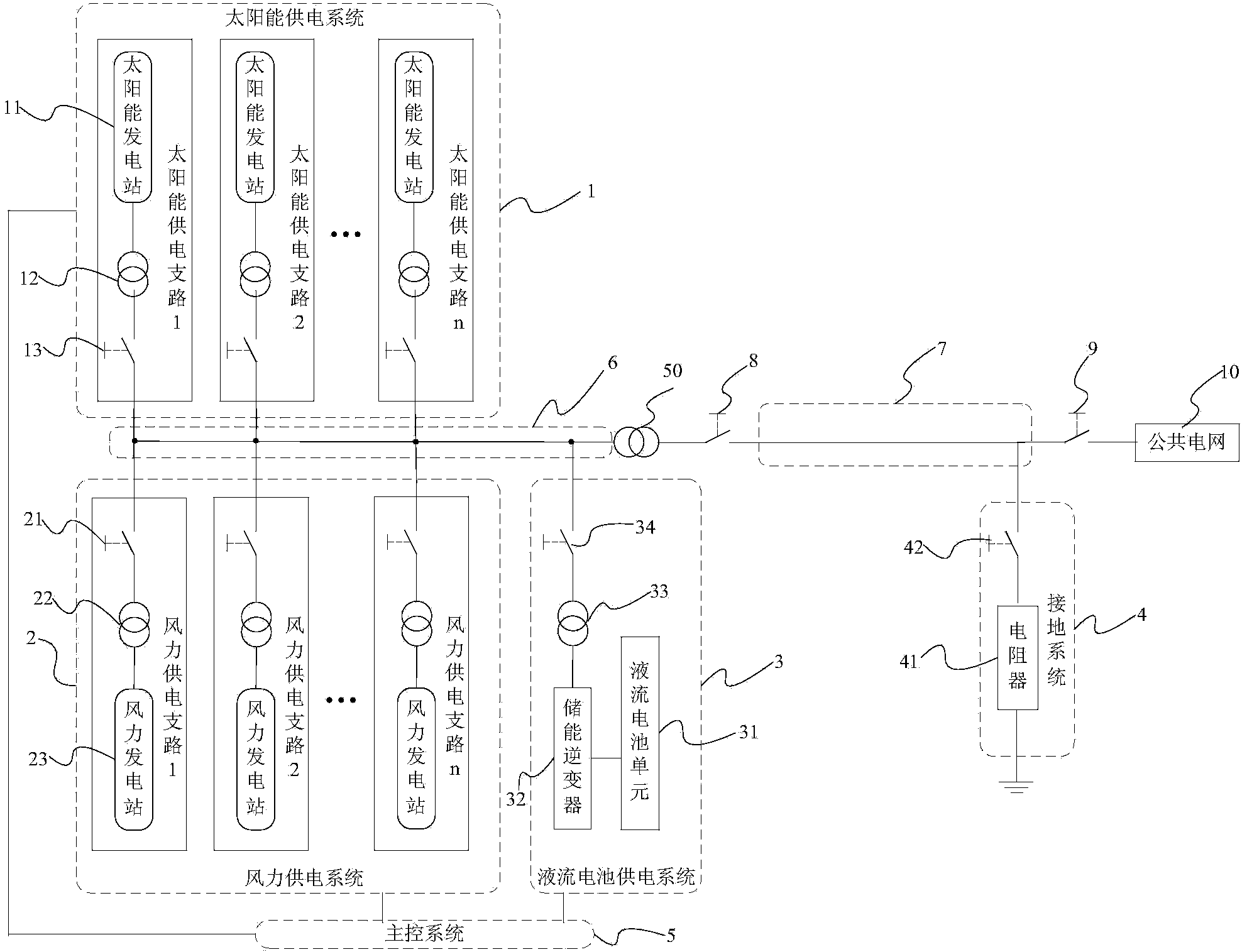

[0044] Such as figure 1 , figure 2 with image 3 A flow battery-based AC ice-melting method shown includes the following steps:

[0045] S1: Connect the end of the power transmission line to be thawed with the grounding system 4 including the resistor 41 and the sixth switch unit 42; one end of the resistor 41 is grounded, and the other end is connected to the end of the power transmission line to be thawed through the sixth switch unit 42 connected, execute S2;

[0046] S2: The main control system 5 according to the formula I C =(D / ρ)[(t s -t)(πh+πσεt 3 +2EVWc w +2EVW E L V ]Calculate the critical current I to prevent icing on the transmission line that needs to be melted C , where D is the wire diameter of the transmission line to be ice-melted, ρ is the resistivity of the wire of the power transmission line to be ice-melted, and t s is the surface temperature of the conductor of the transmission line that needs to be iced, h is the convective heat transfer coeffi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com