Groove-type Schottky power device structure and method for manufacturing same

A technology of power devices and manufacturing methods, applied in the field of trench-type Schottky power device structures and their manufacturing, can solve problems that are difficult to improve, and achieve improved endurance and antistatic capabilities, low leakage, and bidirectional optimization of operating characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

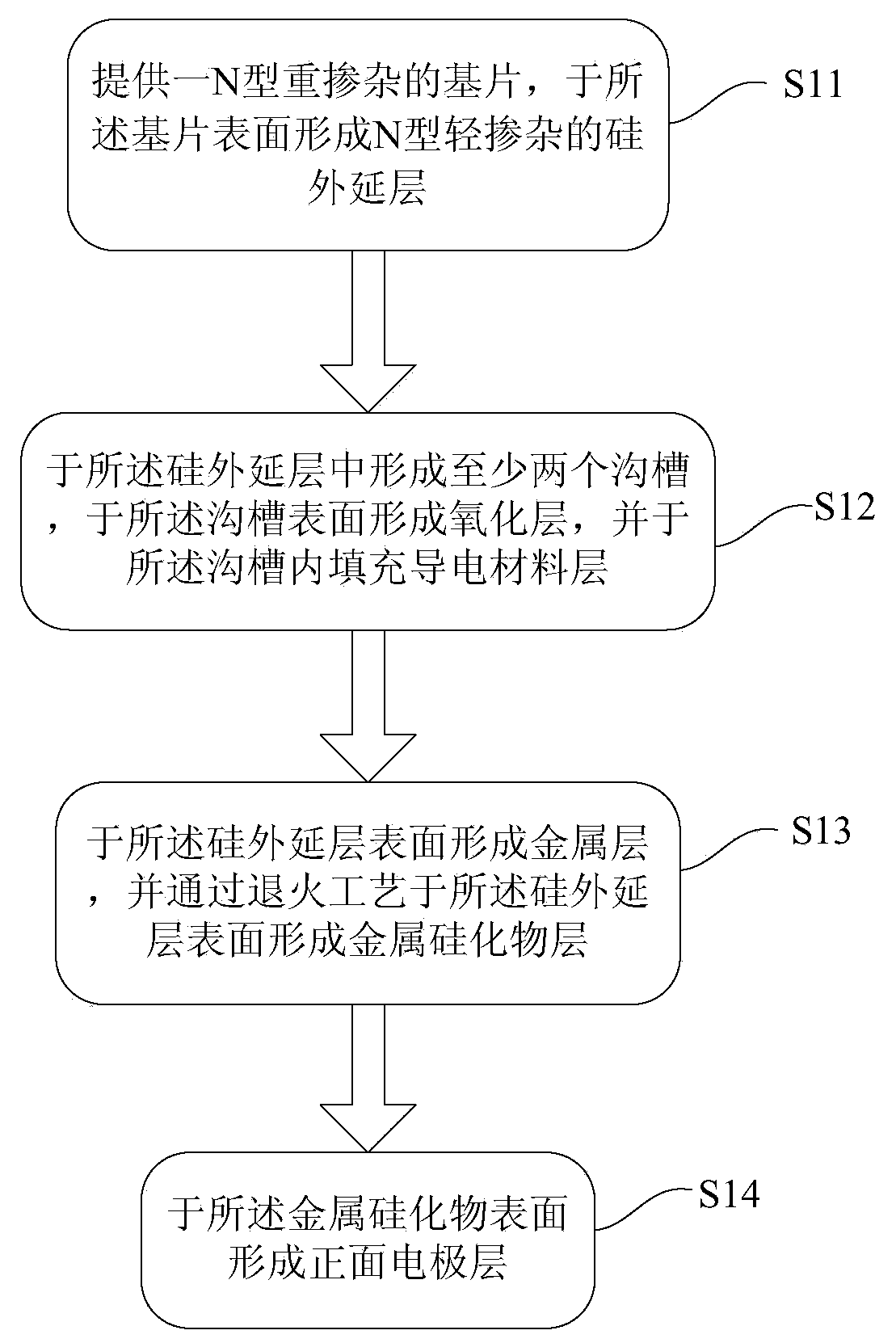

[0089] like Figure 1 to Figure 9 and Figure 11 As shown, this embodiment provides a method for manufacturing a trench Schottky power device structure, the basic steps of which are the same as those of TiN / Ti / Ni / Ag stack, that is, the front electrode is TiN layer 108 , AlSi layer 201 , Ti layer 110 , TiN layer 111 , Ti layer 112 , Ni layer 113 , and Ag layer 114 in order from bottom to top.

[0090] like Figure 11 As shown, this embodiment also provides a trench-type Schottky power device structure, the basic structure of which is the same as that of Embodiment 1, wherein the front electrode is TiN / AlSi / Ti / TiN / TiN / AlSi / TiN / TiN / Ti / Ni / Ag stack, that is, the front electrode is TiN layer 108 , AlSi layer 201 , Ti layer 110 , TiN layer 111 , Ti layer 112 , Ni layer 113 , and Ag layer 114 in order from bottom to top.

Embodiment 3

[0092] like Figure 1 to Figure 9 and Figure 12 As shown, this embodiment provides a method for manufacturing a trench Schottky power device structure, the basic steps of which are the same as those in Embodiment 1, wherein the front electrode is TiN / Al / Ti / TiN / Al / Ti / TiN / Ti / Ni / Ag stack, that is, the front electrode is TiN layer 108 , Al layer 301 , Ti layer 110 , TiN layer 111 , Ti layer 112 , Ni layer 113 , and Ag layer 114 in order from bottom to top.

[0093] like Figure 12 As shown, this embodiment also provides a trench-type Schottky power device structure, the basic structure of which is the same as that of Embodiment 1, wherein the front electrode is TiN / Al / Ti / TiN / TiN / Al / TiN / TiN / Ti / Ni / Ag stack, that is, the front electrode is TiN layer 108 , Al layer 301 , Ti layer 110 , TiN layer 111 , Ti layer 112 , Ni layer 113 , and Ag layer 114 in order from bottom to top.

[0094]As mentioned above, the present invention provides a trench type Schottky power device structure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com