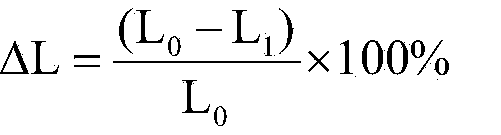

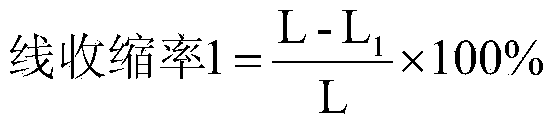

Linear shrinking percentage test method for room temperature vulcanization of liquid silicone rubber

A technology of liquid silicone rubber and linear shrinkage, applied in the direction of material inspection products, etc., can solve the problems of mold size limitation, poor repeatability, insufficient stability, etc., and achieve good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A method for testing the linear shrinkage rate of liquid silicone rubber room temperature vulcanization, comprising the steps of:

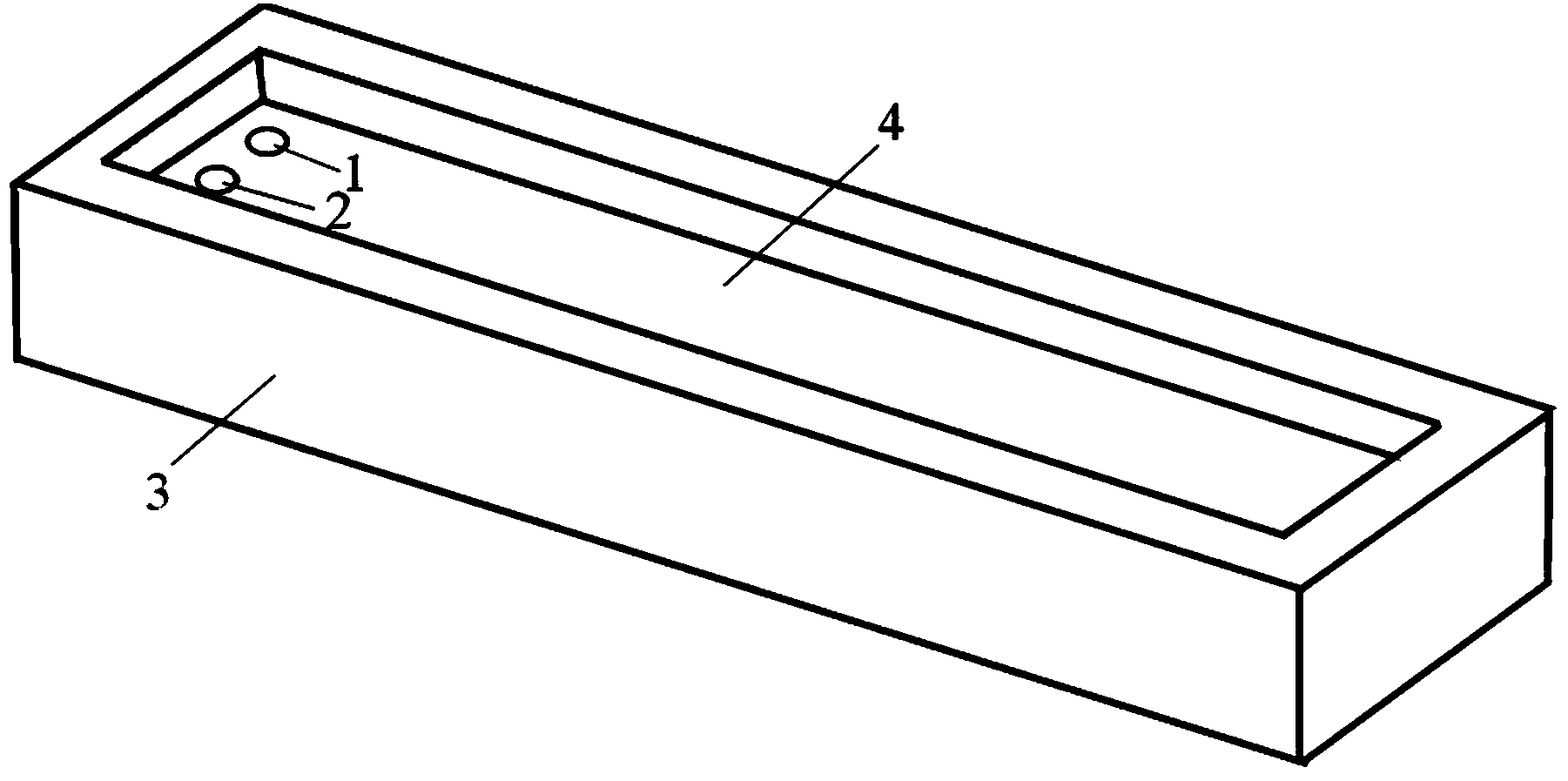

[0047] ①Choose liquid silicone rubber, that is, an appropriate amount of A glue, and then choose B glue, mix and stir evenly, put it into a vacuum defoaming box for 2 to 5 minutes, and put such figure 1 The mold 3 shown is coated with release agent and blown dry with a blower, then pour the defoamed glue into it, scrape the surface of the mold with a scraper, and make the glue level evenly, without pits on the surface, place In a space with a constant temperature of 20-35°C; the test bench where the mold 3 is placed must be horizontal and cannot be tilted;

[0048] Select at least 3 groups of samples, and take different additions of B glue.

[0049]②After 12 to 18 hours of storage, the glue has cured and is not sticky. Gently lift it from the end without fixing holes to the position with holes, but do not destroy the position where the glu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com