Experiment system for measuring migration and sedimentation of granular corrosion products in pipeline

A technology of corrosion products and experimental systems, applied in the field of multiphase flow measurement, can solve problems that have not been disclosed before

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

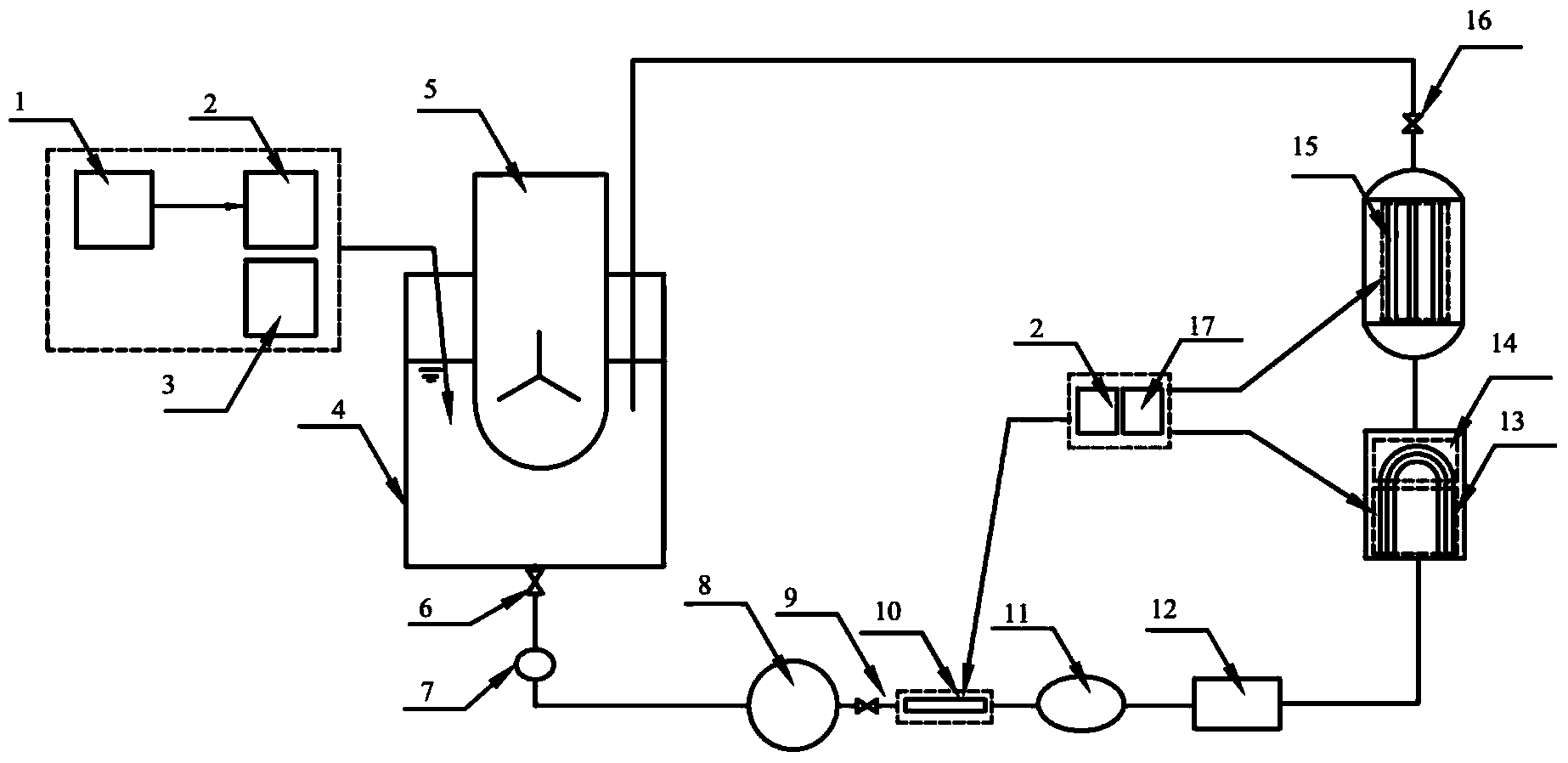

[0025] The invention provides an experimental system for measuring the migration and deposition of granular corrosion products in pipelines. The invention will be further described below in conjunction with the accompanying drawings and specific examples.

[0026] like figure 1 As shown, a mixing device 5 is set in the water tank 4, and a pipeline is set at the bottom of the water tank 4, which is connected with the first valve 6, the transition section 7, the pump 8, the gate valve 9, the first test section 10, the turbine flowmeter 11, the pressure gauge 12, The second test section 13 , the third test section 14 , the fourth test section 15 , and the second valve 16 are sequentially connected and connected back to the water tank 4 .

[0027] Obtain the desired particle size range through a specific mesh 1, and weigh it with a precision balance 2 (with an accuracy of 1 / 10,000), and place the particles to be tested with known particle size and mass in the water tank 4, The ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com