Drawing force testing mechanism and drawing force testing method

一种测试机构、拉拔力的技术,应用在使用施加稳定的张力/压力测试材料强度、力/扭矩/功测量仪、测量力等方向,能够解决设备成本上升、测试结果偏差、拉拔力测试机构零件繁多等问题,达到控制设备成本、保证准确性、简化拉拔力测试机构的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

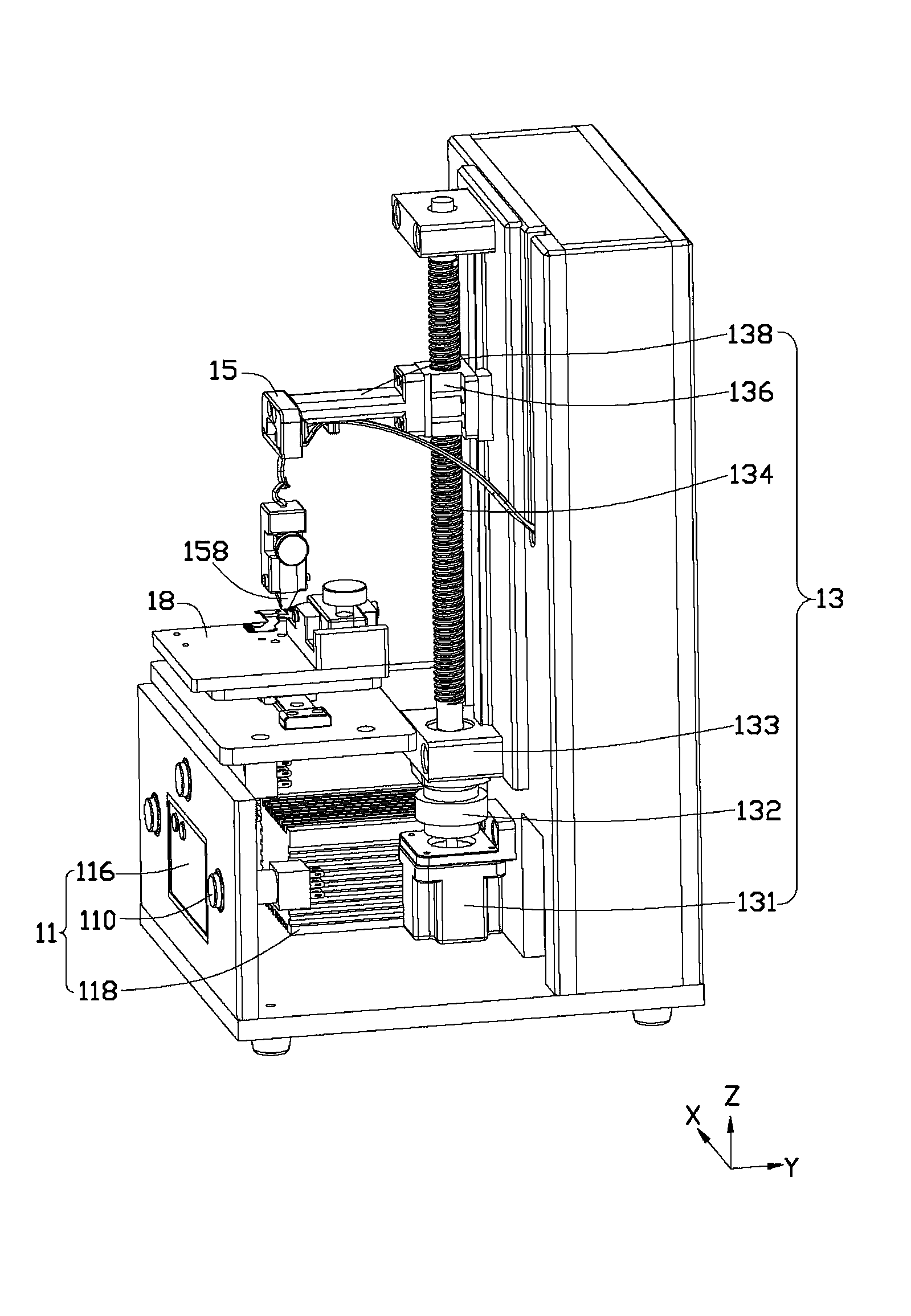

[0063] see figure 1 and figure 2 , figure 1 It is a three-dimensional schematic diagram of a preferred embodiment of the pulling force testing mechanism of the present invention. figure 2 yes figure 1 A three-dimensional schematic diagram of the internal structure of the pull-out force testing mechanism shown. The pull-out force testing mechanism 1 is used to verify the reliability of the product to be tested that is integrated by welding, for example, the reliability between the cable and the cable, the motherboard and the cable that are integrated by welding. This embodiment is described by taking the welding of the cable and the main board as an example, wherein one end of the cable to be tested is welded to the main board to be tested by a welding method.

[0064] The pull-out force testing mechanism 1 includes a housing 10 , a control system 11 , a driving and transmission device 13 , a loading device 15 and a material clamping device 18 .

[0065] The housing 10 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com