Hole bottom vibration simulation test bed

A technology for simulating test benches and hole bottoms, applied in the field of test benches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing, the present invention will be further described:

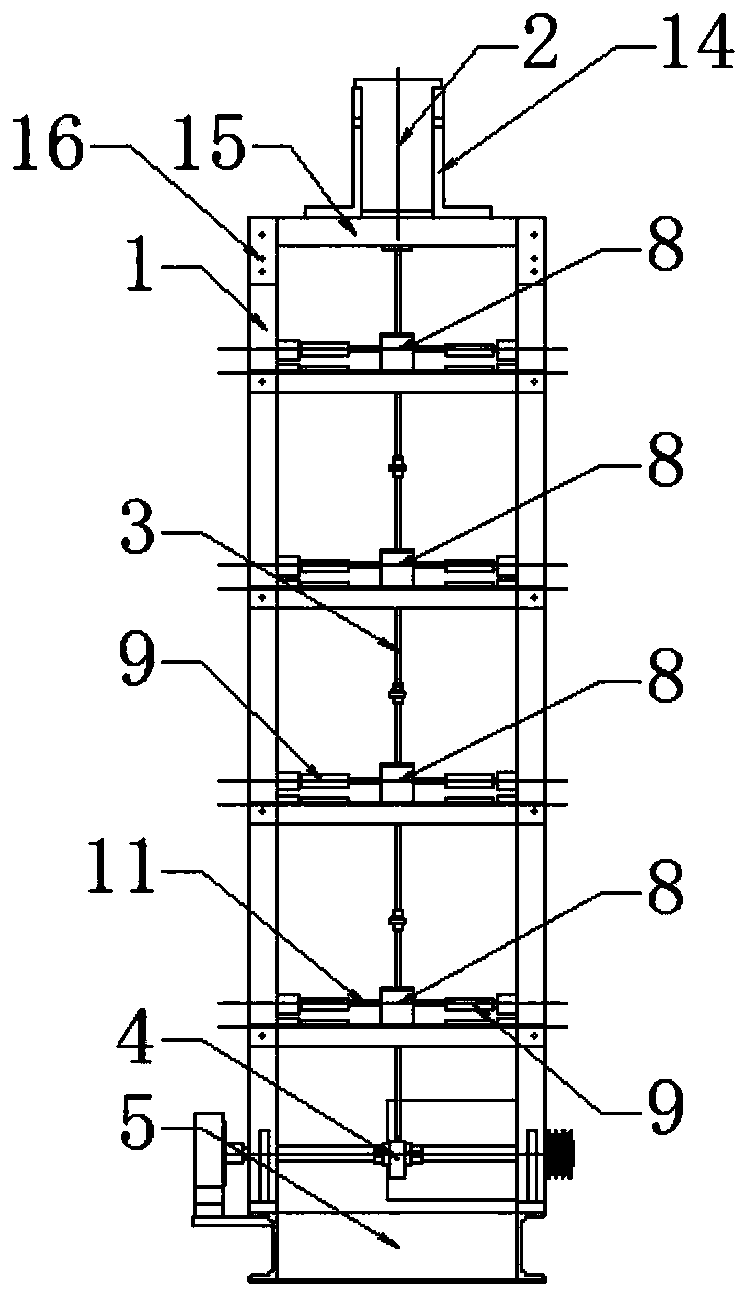

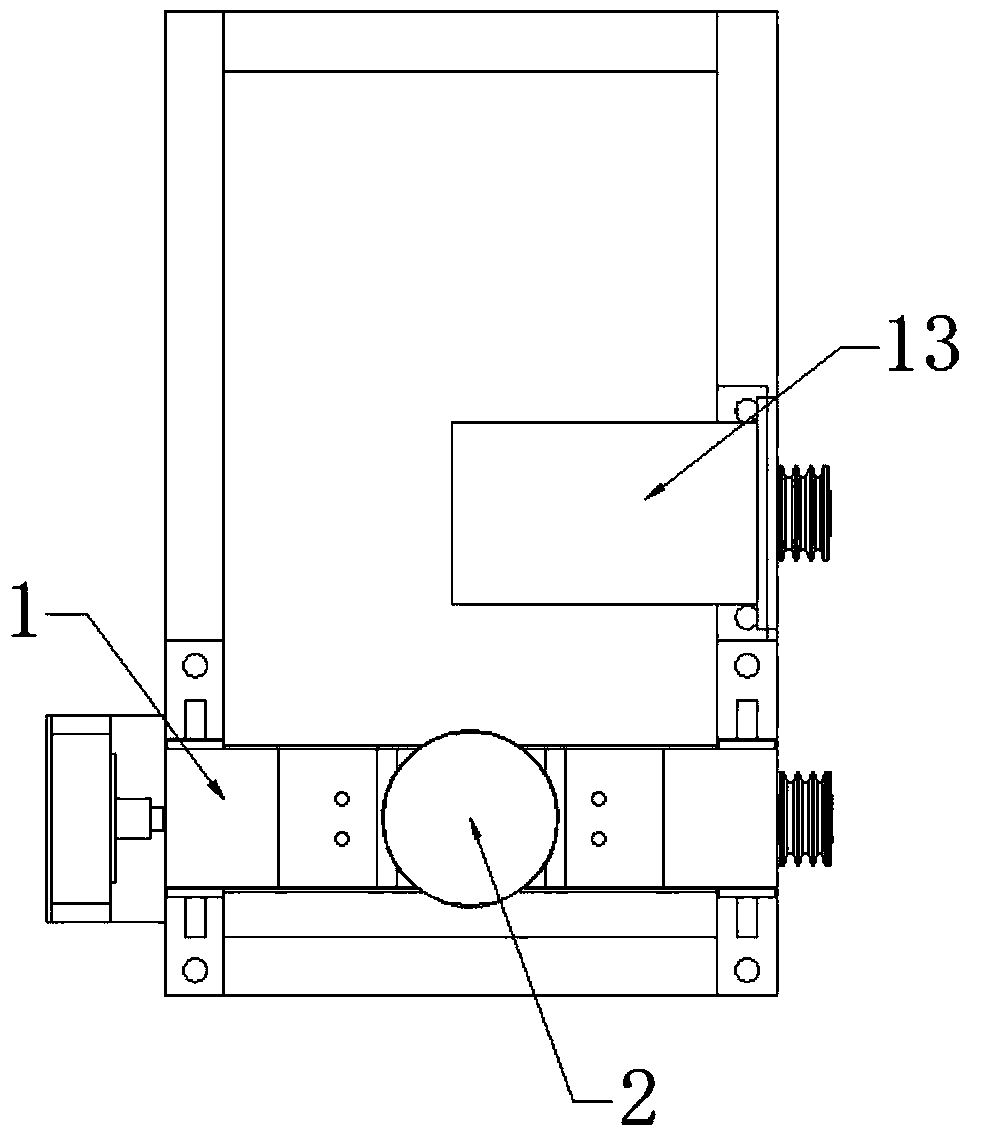

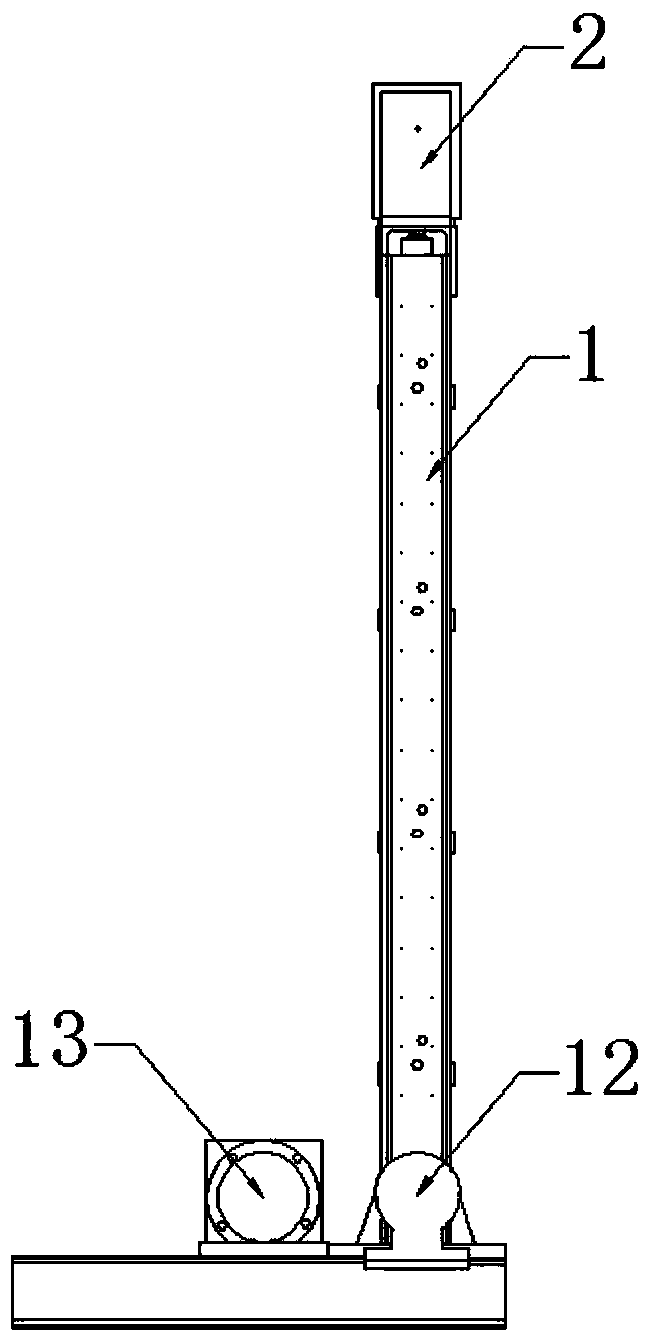

[0028] Please refer to figure 1 with image 3 , figure 1 It is a schematic structural diagram of the front view of the hole bottom vibration simulation test bench of the present invention; image 3 It is a side view structural schematic diagram of the hole bottom vibration simulation test bench of the present invention.

[0029] A hole bottom vibration simulation test bench, comprising an upper vibration source, a lower vibration source, a supporting platform 1 and a measurement and control unit, the upper vibration source is arranged above the supporting platform 1, and the lower vibration The source is arranged below the support platform 1, and a simulated drilling tool 3 is arranged in the support platform 1, the upper end of the drilling tool 3 is connected to the upper excitation source, and the lower end of the drilling tool 3 is connected to the upper vibration s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com