Chain tensioning gear and method for slag removing machine

A technology of chain tensioning device and slag scraper, which is applied in the direction of transmission device, belt/chain/gear, mechanical equipment, etc. The effect of alleviating shock loads, improving service life and operating reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

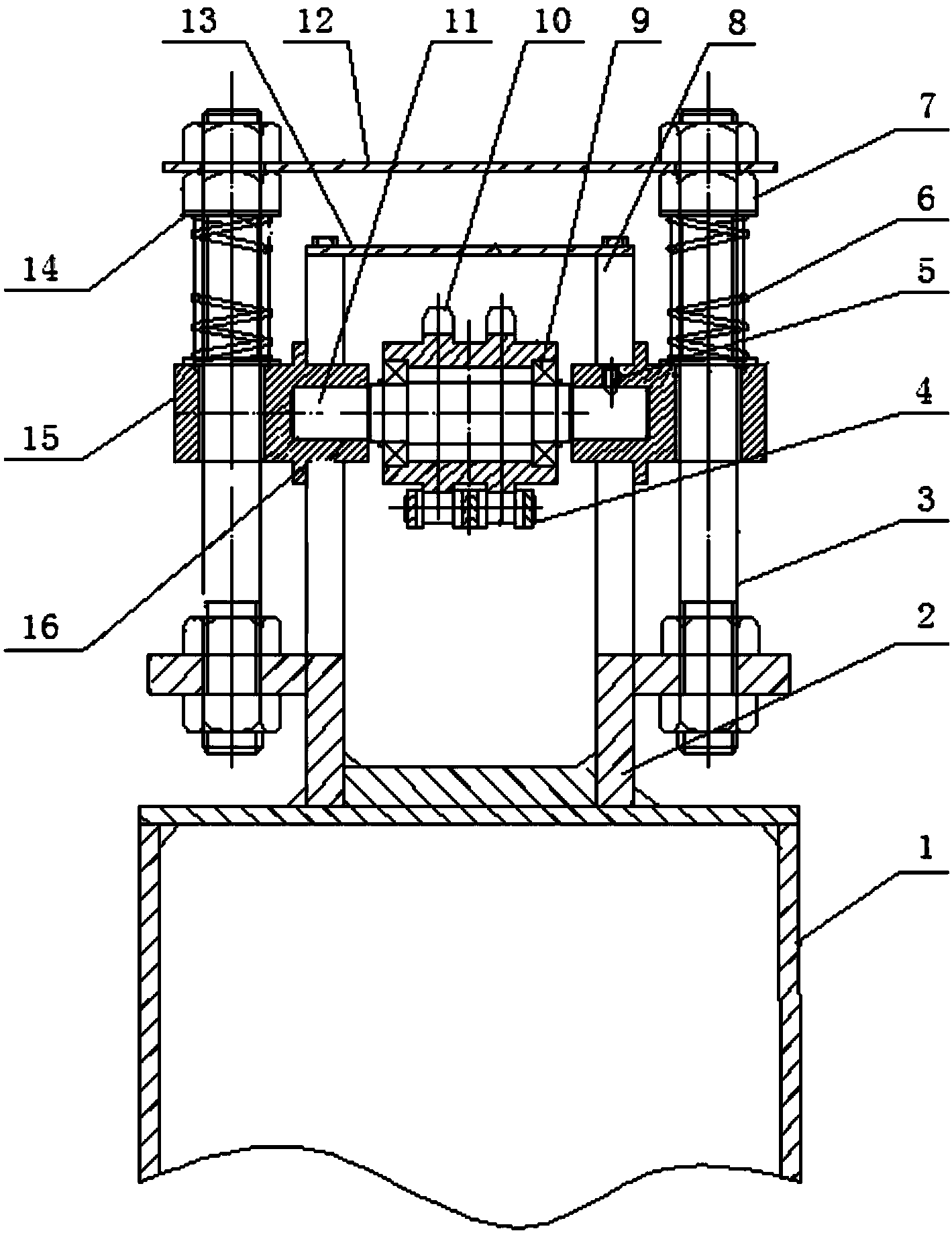

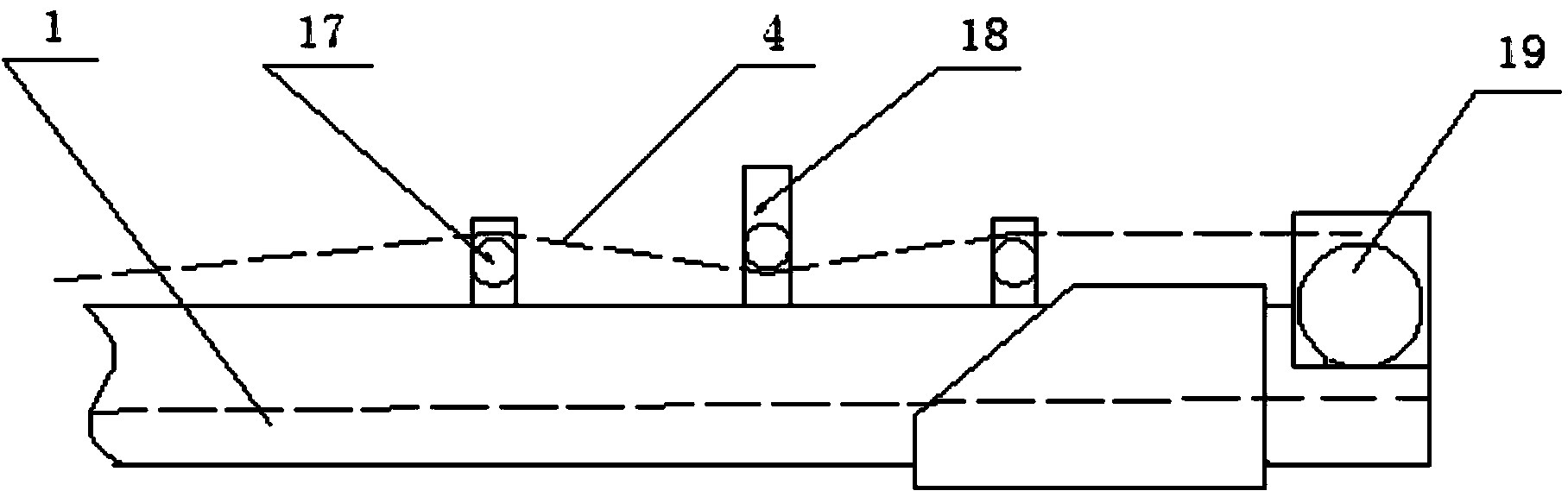

[0020] Depend on figure 1 It can be seen that the chain tensioning device of the slag removal machine of the present invention is mainly composed of a support cross arm 1, a fixed seat 2, a support screw 3, a chain 4, a spring 6, an adjustment nut 7, a slideway support 8, a bearing 9, and a tensioning sprocket 10. It is composed of sprocket shaft 11, screw connecting plate 12, support connecting plate 13, slide block 15 and related connectors.

[0021] Slide block 15 is two, is processed with circular end hole in the inner end of slide block 15, is provided with a limit stop 16 in the middle, and the outside has the screw rod hole that supports screw rod 3 is installed. The fixed seat 2 is in the shape of a "U" as a whole, and a horizontal plate protruding outward is welded on the upper end of the "U" shape. A slideway support 8 is respectively fixed on the inner side of the horizontal plate, and the two slideway support 8 The upper ends are fixed together by the support conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com