Bladeless fan structure

A bladeless fan and fan assembly technology, which is applied to liquid variable volume machinery, non-variable volume pumps, variable volume pump components, etc. Effects of flow and noise, low noise, low wind loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

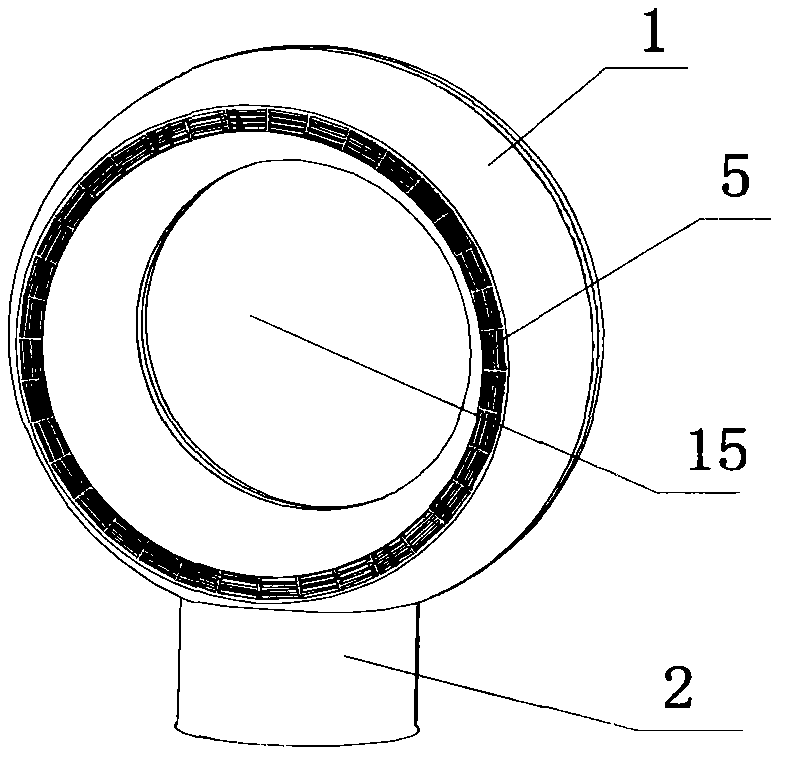

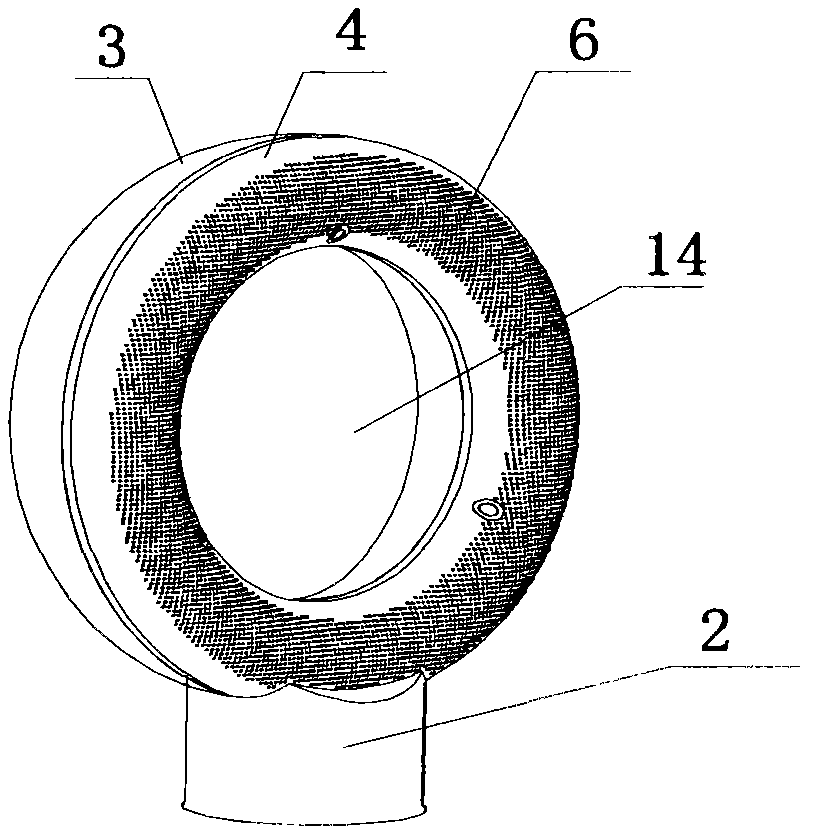

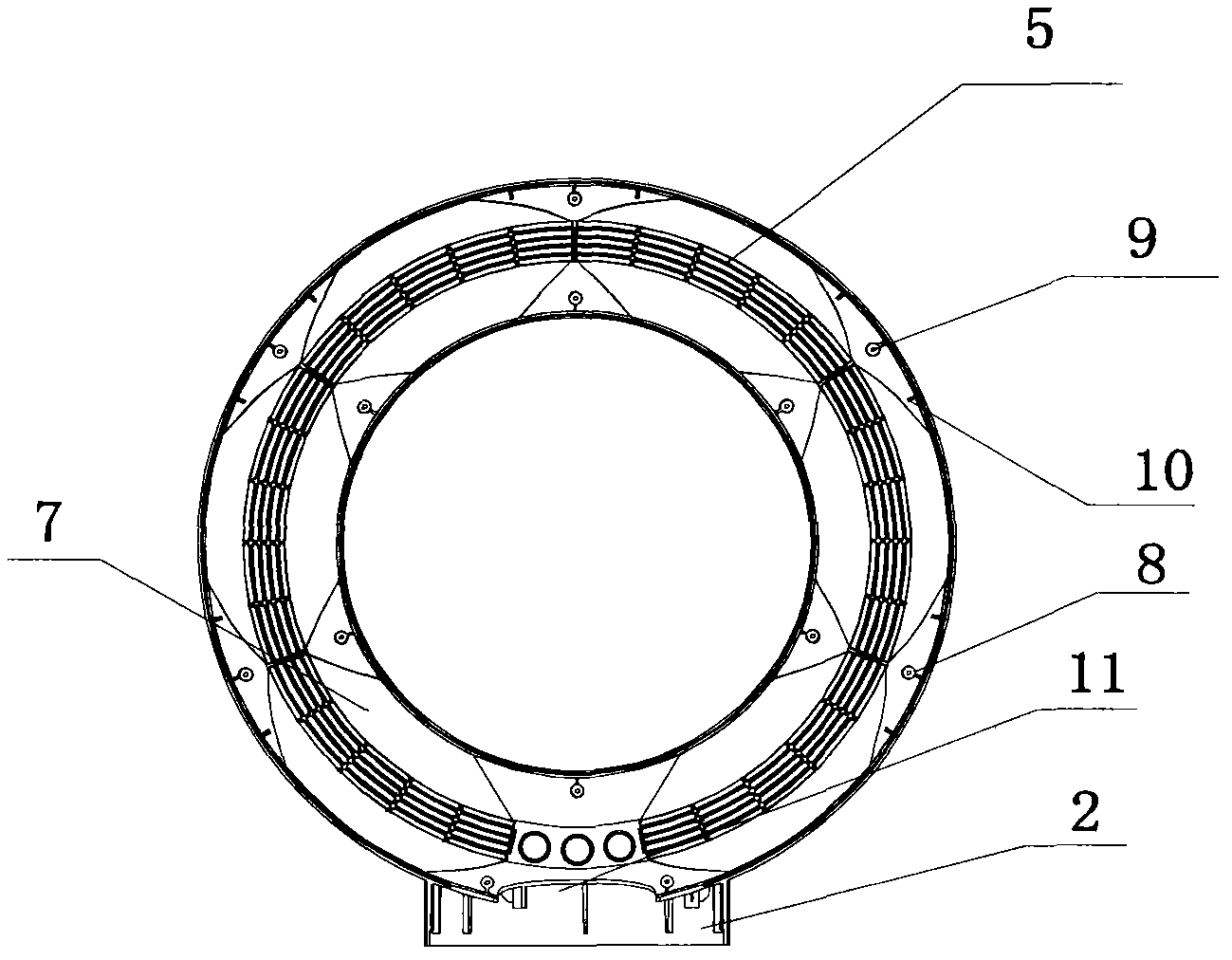

[0021] like figure 1 and 2 As shown, a bladeless fan structure includes a circular housing 1, a cylindrical connection body 2 is connected below the housing 1, and the axis of the housing 1 and the axis of the connection body 2 are perpendicular to each other. The case 1 is composed of a front case 3 and a rear case 4 . Both the front casing 3 and the rear casing 4 are circular. The cross-sections of the front housing 3 and the rear housing 4 are "U"-shaped, and the width of the cross-section of the front housing is narrowed from the opening end of the "U" shape to the connecting end of the "U" shape. The width of the cross section is the same. An air outlet 5 is provided on the front housing 3 . The air outlet 5 is annular. The rear housing 4 is provided with an air inlet 6, the air inlet 6 is annular, the air inlet 6 and the air outlet 5 are parallel to each other, and the air inlet 6 is formed by uniformly distributed circular holes arranged on the rear housing. The wi...

Embodiment 2

[0025] like Figure 7 As shown, a bladeless fan structure includes an annular casing 1, and the casing 1 is composed of a front casing 3 and a rear casing 4. The front casing 3 and the rear casing 4 have the same shape and are also circular. Different from Embodiment 1, a square notch 16 is provided on the bottom surface of the "U"-shaped inner wall of the front housing 3 and the rear housing 4, which has a larger diameter. The square notch 16 forms a plane, so that form a support.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com