Bevel gear set reversing underground pulse jet supercharging device

A technology of pressurization device and pulse jet, which is applied in the direction of drilling with vibration, drilling with liquid/gas jet, etc., can solve the problems of short life, reduction, and inability to continuously provide pressurization effect, etc., and achieve long service life, low wear and tear. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

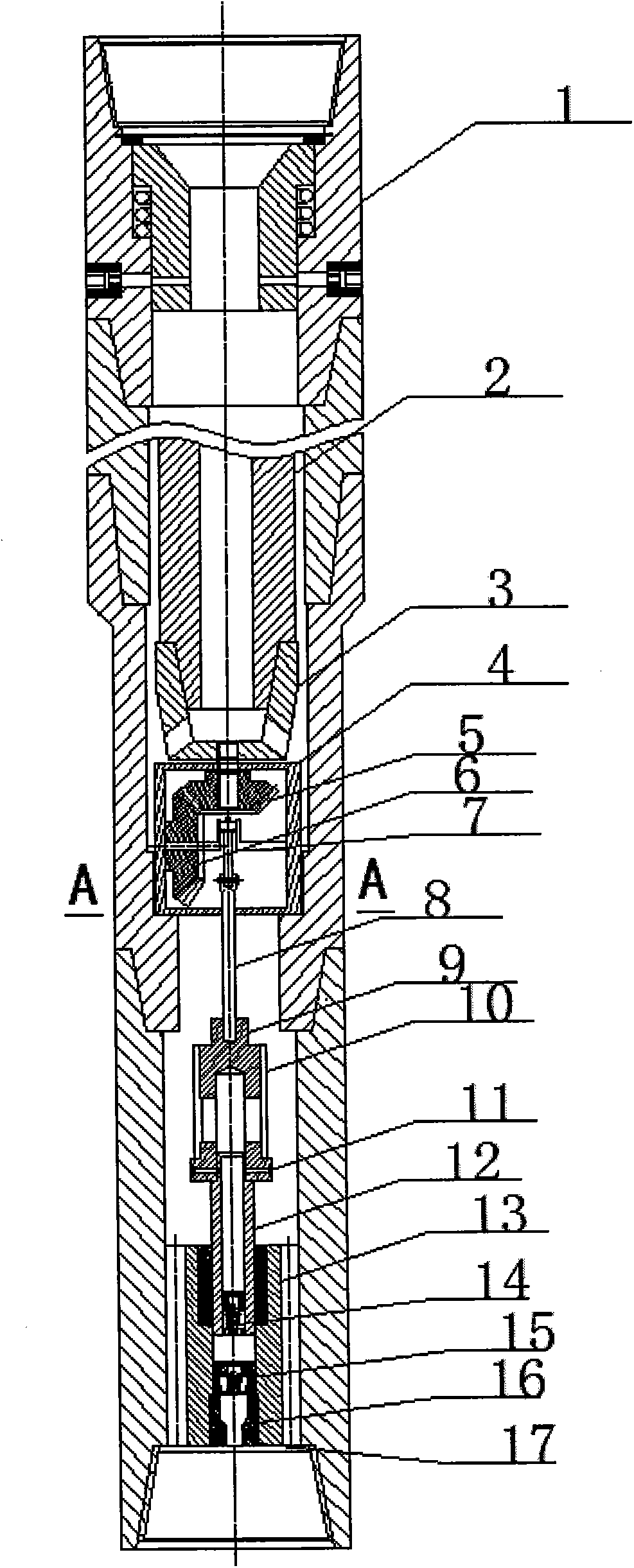

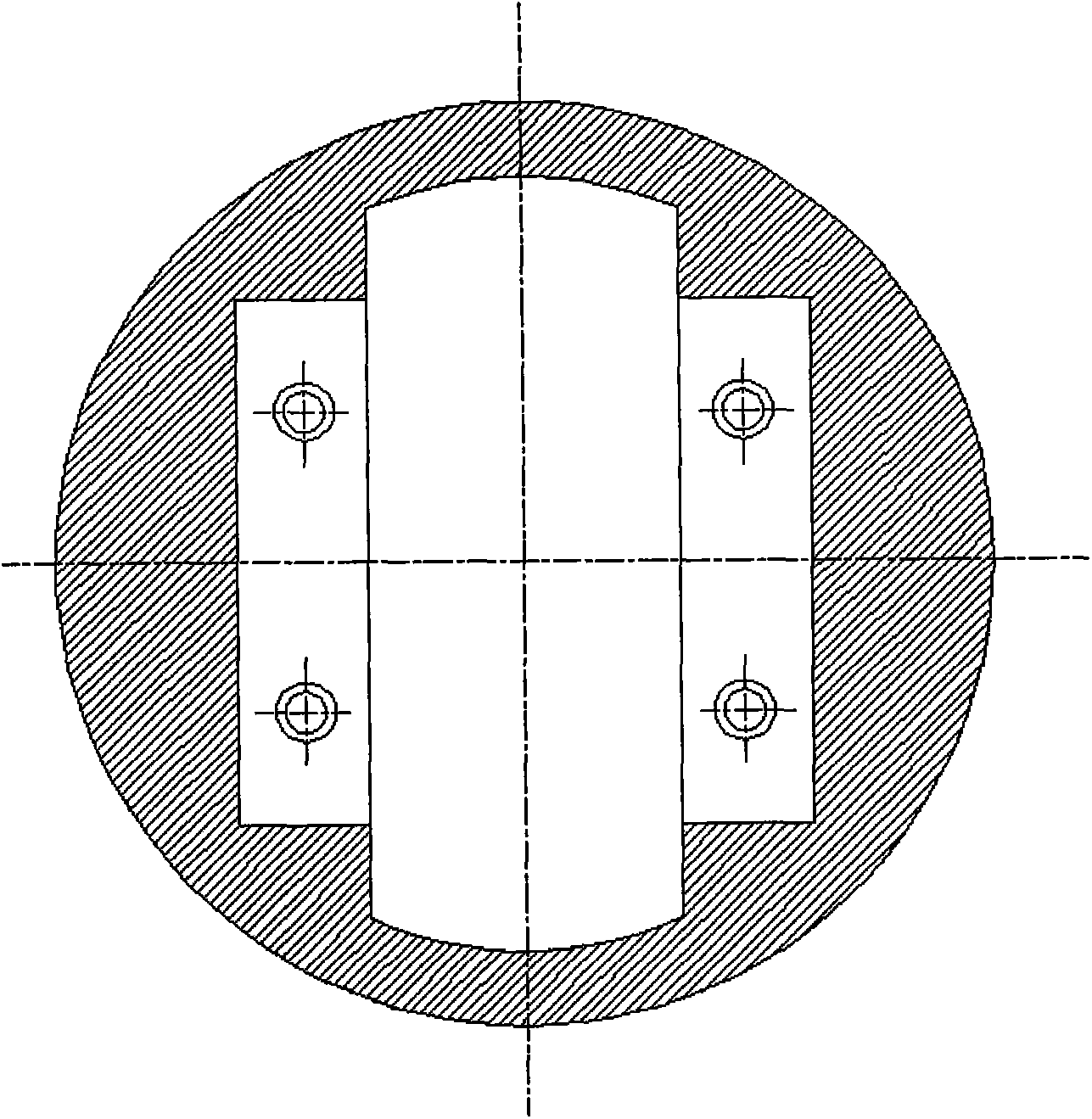

[0012] exist figure 1 Among them, the lower end of the bypass valve (1) is connected with the upper end of the screw motor (2) through a screw, the lower end of the power source screw motor (2) is connected with the transmission device (3) through a screw, and the transmission device (3) is connected with the bevel gear set The driving gear (5) of the reversing mechanism (4) is connected and rotates together with the screw motor (2), and the drilling fluid flows into the tool through the liquid outlet on the transmission device (3); the conical gear set reversing mechanism (4 ) The internal driving gear (5) is coaxially connected with the transmission device (3), the driving gear (5) drives the driven gear (6) to move, the crankshaft (7) is coaxially connected with the driven gear (6), and the driven gear ( 6) Drive the crankshaft (7) to move, thereby driving the connecting rod (8) to reciprocate up and down, the crankshaft (7) rotates once, and the plunger (12) completes a re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com