Shielding box for vacuum coating

A technology of vacuum coating and shielding box, which is applied in vacuum evaporation coating, sputtering coating, ion implantation coating, etc. It can solve the problems of unstable metal layer adhesion, difficult cleaning, coating defects of the coated workpiece, etc., to achieve Improve optical and mechanical properties, reduce the loss of manpower and material resources, and reduce the effect of coating defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

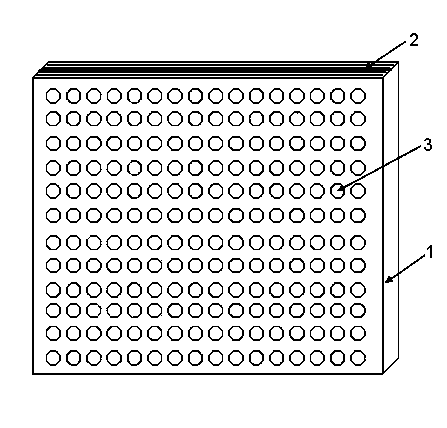

[0015] like figure 1 Shown: a shielding box for vacuum coating, including a casing 1 and a shielding sheet 2, the casing 1 and the shielding sheet 2 are made of steel, copper, aluminum or alloy materials, and inside the casing 1 there are multiple Independently arranged shielding sheets 2, the shielding sheets 2 are arranged in parallel with each other and each shielding sheet 2 is provided with a plurality of through holes 3, the through holes 3 are evenly distributed on the shielding sheets 2 and the through holes on any two shielding sheets 2 The holes 3 are all corresponding to each other. Specifically, the housing 1 is shaped like an “凵” and grooves are formed on the inner wall of the housing 1 , and each shielding piece 2 is inserted into the housing 1 along the corresponding groove.

[0016] The shielding box adopted in the present invention ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com