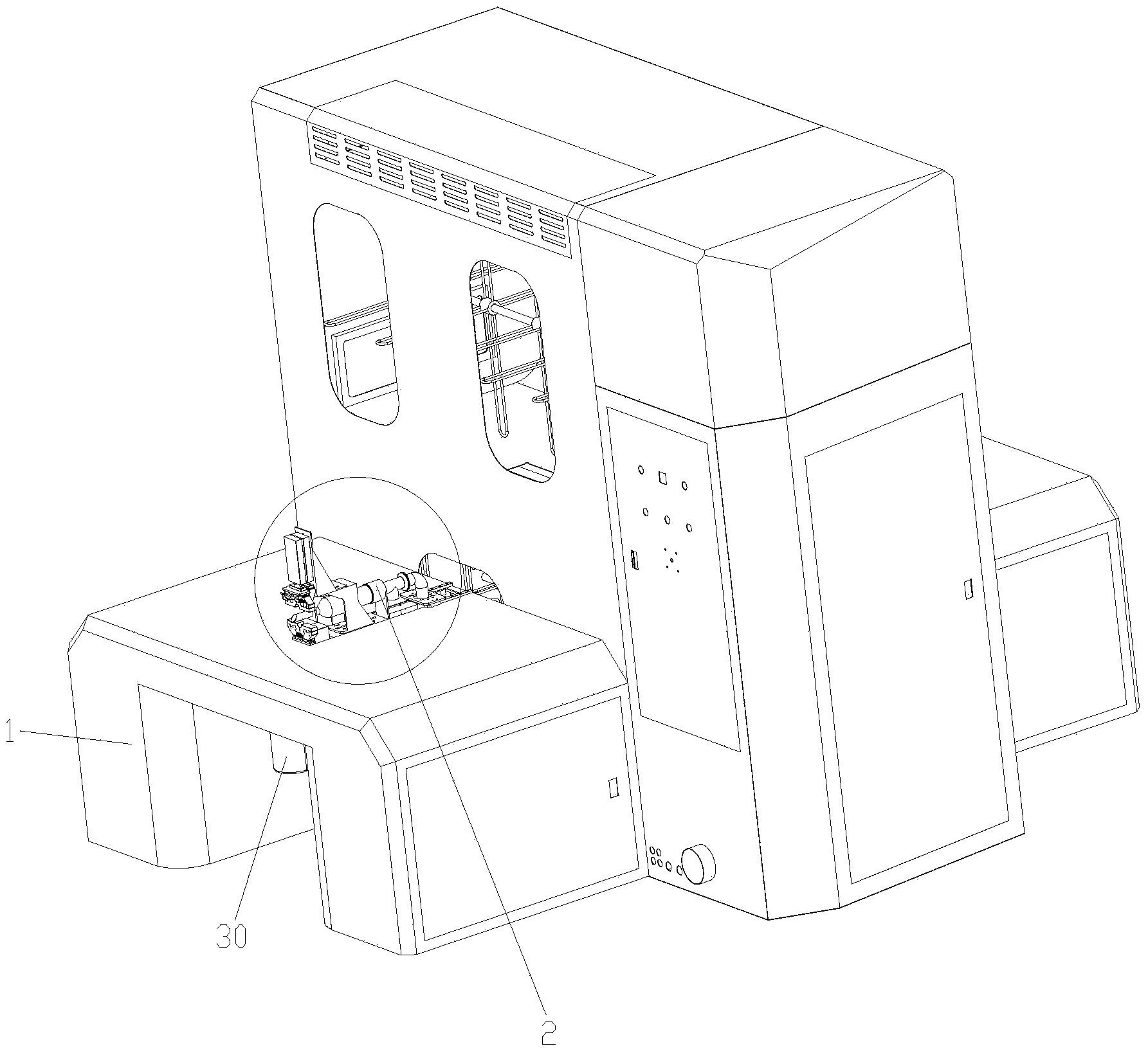

Novel full-automatic down filling machine

A fully automatic and new type of technology, which is applied to household appliances, tools for sewing clothes, and the production of furniture covers. Guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

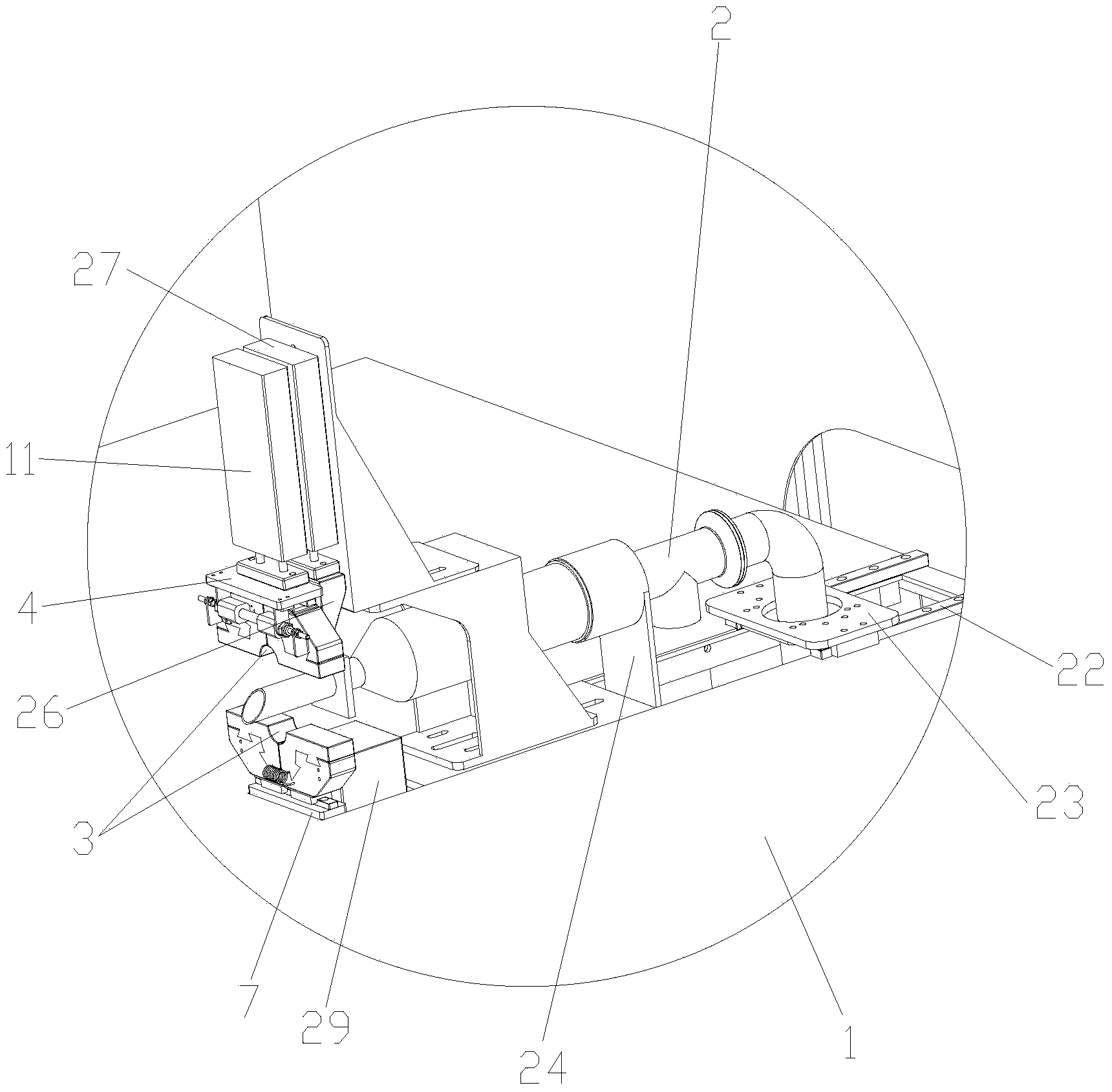

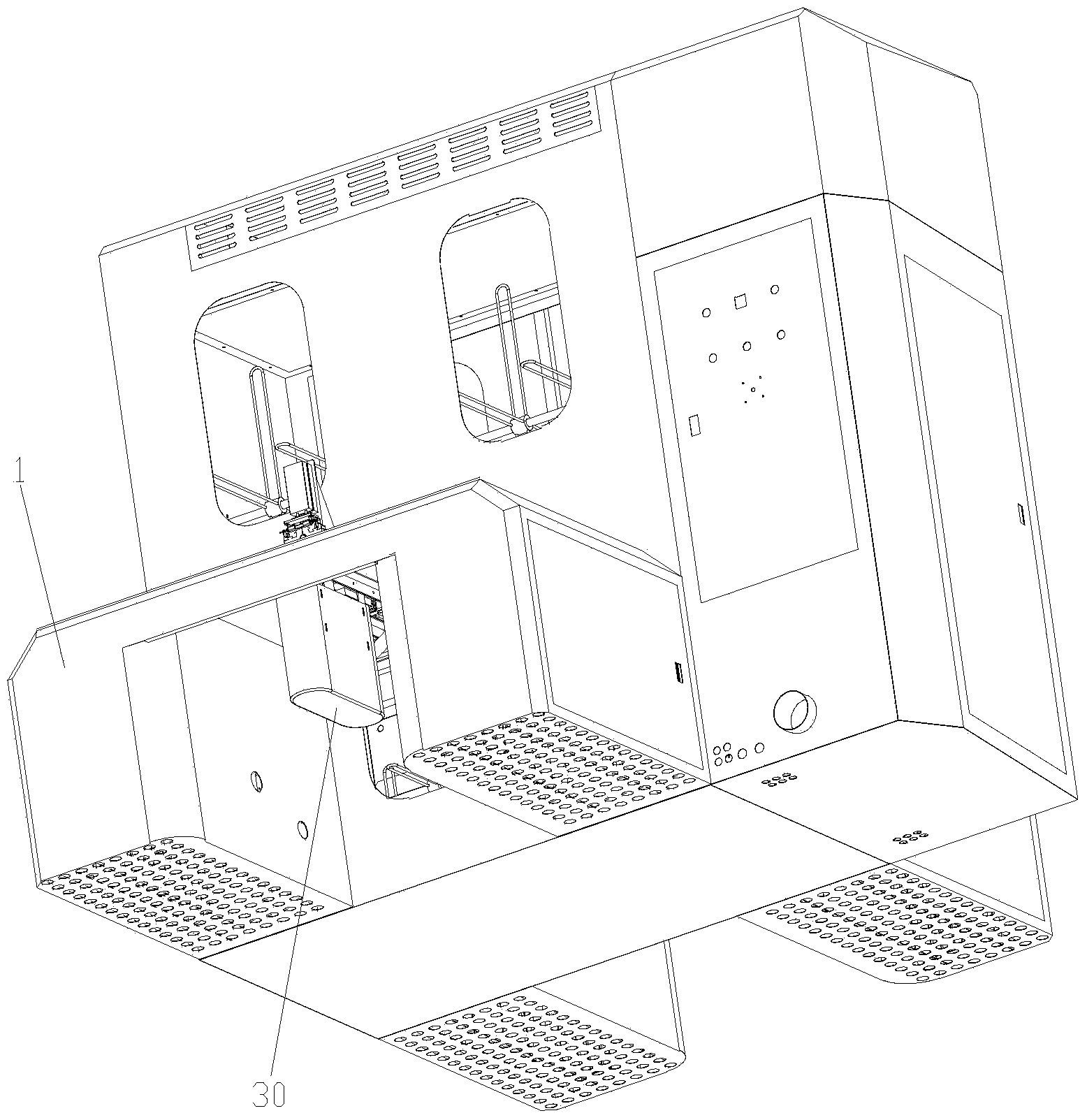

Embodiment 1

[0029] as attached Figure 1-6 As shown, the sealing device is located inside the locking clip device; the telescopic device includes a second slide rail 22, a slide piece 23, a connecting piece 24 and a fifth cylinder 25 that controls the horizontal movement of the connecting piece; the second slide rail 22 Set on the table top of the weighing cabinet 1; the sliding piece 23 is connected to the tail of the down filling tube 2 and arranged on the second slide rail 22; the connecting piece 24 is arranged on the down filling tube 2; the connecting piece 24 The lower end of the lower end of the weighing cabinet is located below the table top of the weighing cabinet 1; the fifth cylinder 25 is arranged below the weighing cabinet 1; the fifth cylinder 25 is connected to the connecting piece 24; when the fifth cylinder 25 is started, it drives the filling The tube 2 moves inward; the sealing device includes an upper pressing block 26, a sixth cylinder 27 that controls the upper pres...

Embodiment 2

[0032] The sealing device is located outside the clamping device, and the telescopic device controls the outward movement of the sealing device. The other principles are the same as those in Embodiment 1.

[0033] In the novel fully automatic down filling machine of the present invention, after the filling of the feather cuttings is completed, the portion to be sealed of the cuttings is flattened, and then the sealing device seals the cuttings, thereby ensuring the quality of the sealing and further ensuring the quality of down products. the quality of.

[0034] In the new full-automatic down filling machine mentioned above, rubber pads are provided under the first clamping block and the second clamping block, and above the third clamping block and the fourth clamping block, which increases the first clamping The friction force between the lower surface of the block and the second clamping block, and the upper surface of the third clamping block and the fourth clamping block m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com